Water faucet convenient to mount

A faucet, a convenient technology, applied in the field of faucets, can solve problems such as low production efficiency, high process requirements, and large labor investment, and achieve the effects of saving manpower and material resources, simplifying the installation process, and reducing errors and omissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

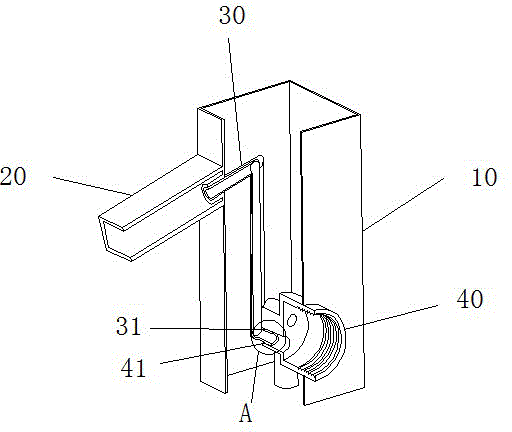

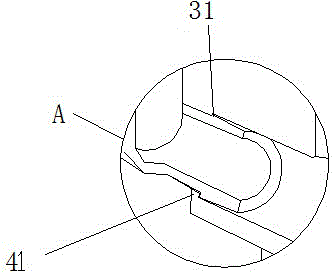

[0014] Such as figure 1 , 2 As shown, the conveniently installed water faucet of this embodiment includes an outer cavity 10, a drain port 20, a water outlet pipe 30 and a valve seat 40 arranged inside the outer chamber 10, and a convex rib 31 is provided at the joint between the water outlet pipe 30 and the valve seat 40. , the valve seat 40 is provided with a groove 41 at the junction of the water outlet pipe 30 . The length of the rib 31 is 10mm, and the depth of the groove 41 is 10mm. Both the valve seat (40) and the water outlet pipe (30) are made of plastic. When installing, squeeze the water outlet pipe 30 into the valve seat 40 until the convex rib 31 is firmly engaged with the groove 41, and then pull it outward until it is confirmed that the convex rib 31 and the groove 41 are tightly combined before installing other components. . The conveniently installed faucet of this embodiment adopts the core-pulling process and does not need to use the foundry process, so ...

Embodiment 2

[0016] Such as figure 1 , 2 As shown, the conveniently installed water faucet of this embodiment includes an outer cavity 10, a drain port 20, a water outlet pipe 30 and a valve seat 40 arranged inside the outer chamber 10, and a convex rib 31 is provided at the joint between the water outlet pipe 30 and the valve seat 40. , the valve seat 40 is provided with a groove 41 at the junction of the water outlet pipe 30 . Both the valve seat 40 and the water outlet pipe 30 are made of plastic. When installing, squeeze the water outlet pipe 30 into the valve seat 40 until the convex rib 31 is firmly engaged with the groove 41, and then pull it outward until it is confirmed that the convex rib 31 and the groove 41 are tightly combined before installing other components. . The conveniently installed faucet of this embodiment adopts the core-pulling process and does not need to use the foundry process, so it can save a lot of manpower and material resources, and reduce the production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com