Control grip clutch mechanism of processing machinery

A technology of processing machinery and clutch mechanism, which is applied in the direction of mechanically driven clutches, mutually meshing clutches, clutches, etc., and can solve problems such as personnel injury, tripping, and item damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples illustrate possible implementations of the present invention, but they are not intended to limit the protection scope of the present invention and are described in advance.

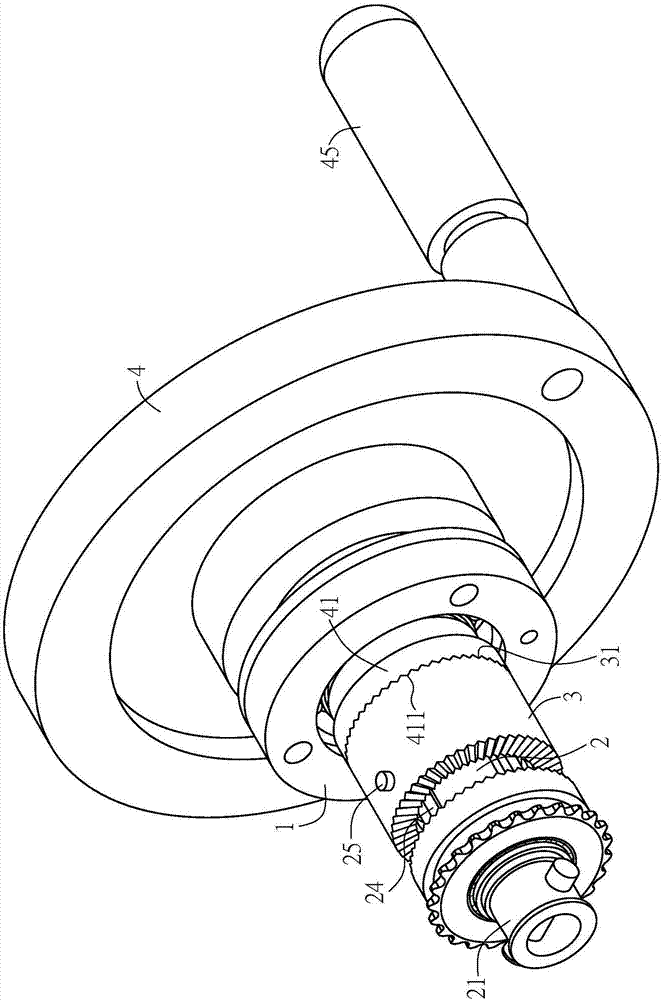

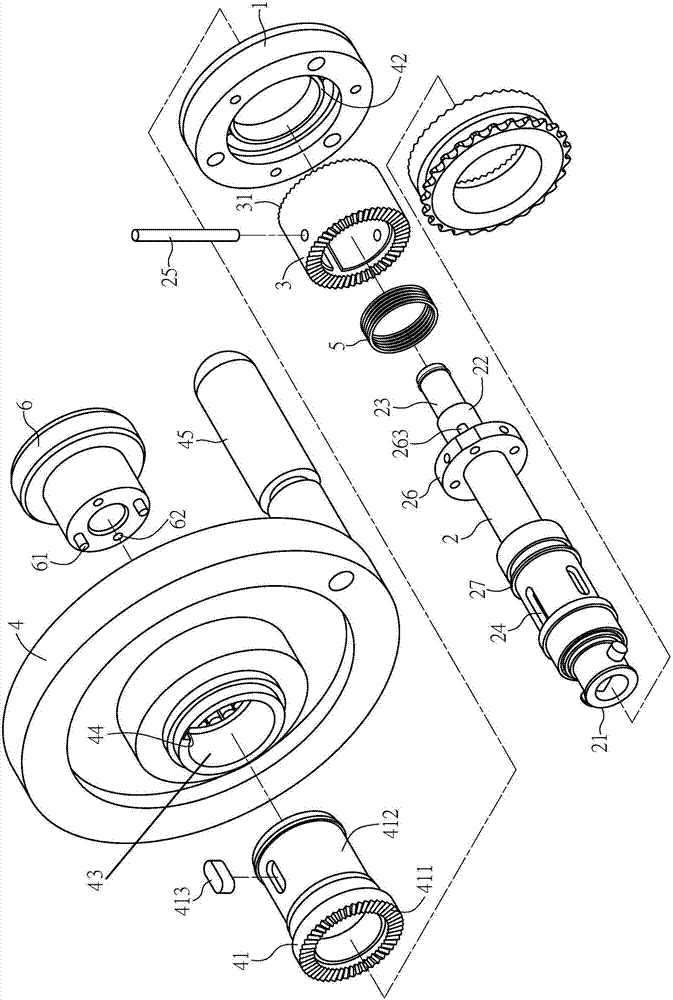

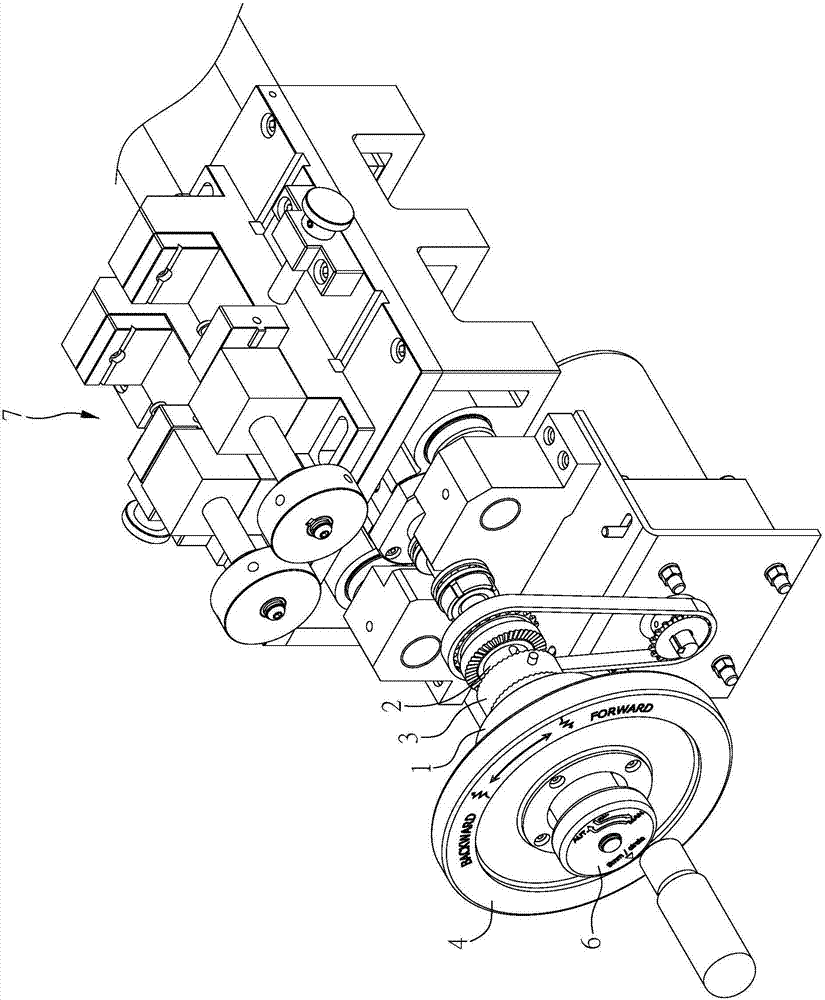

[0033] see Figure 1 to Figure 8 What is shown in the figure is the selected embodiment structure of the present invention, which is for illustration only, and is not limited by this structure in the patent application.

[0034] This embodiment provides a control handle clutch mechanism of a processing machine, such as Figure 1 to Figure 2 As shown, it includes a pivot joint seat 1, an axial tube 2, a movable block 3, an operation wheel 4, an elastic member 5, and a control member 6. The aforementioned processing machine takes a cutting machine as an example in this embodiment, as image 3 As shown, the flying control grip clutch mechanism of this embodiment is combined with the transmission mechanism 7 of the cutting machine, wherein:

[0035] Such as figure 2 and Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com