A new type of plate pump type oil retaining cylinder oil retaining structure for vertical hydro-generator

A hydro-generator and oil-blocking cylinder technology is applied in the directions of hydropower generation, engine components, machines/engines, etc., to achieve the effects of good oil-blocking effect, easy processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

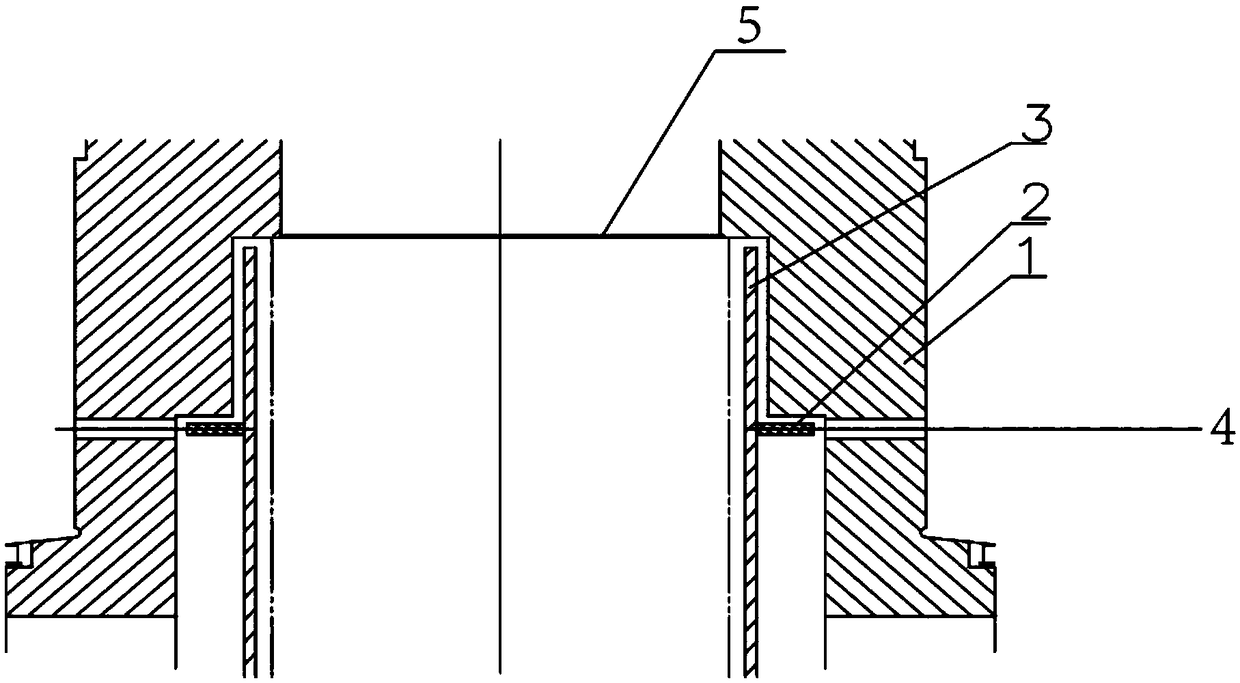

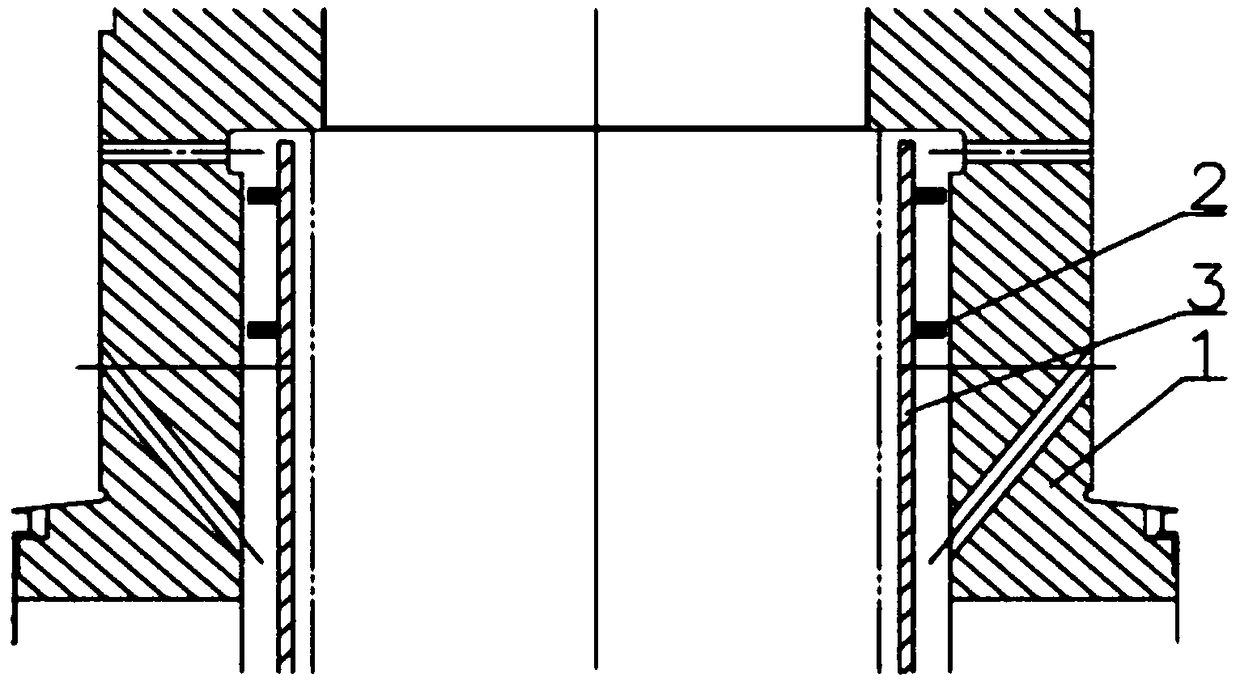

[0011] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0012] A new type of plate-pump type oil-retaining cylinder oil-retaining structure for a vertical hydro-generator, comprising: a thrust head 1, a ring 2, an oil-retaining cylinder 3 and an upper frame 5, characterized in that the center of the upper guide pad of the thrust head A circle of holes is evenly opened at the line height, and an oil retainer 3 is arranged on the upper frame 5, and the oil retainer 3 and the upper frame 5 are fixed and welded to each other, and a ring is arranged on one side of the oil retainer 3. 2. The ring 2 and the oil retaining cylinder 3 are fixed and welded to each other 3, and the ring 2 is flush with the center line 4 of the guide bearing bush. Such as figure 1 , the key points of the design of the present invention are: the present invention opens a circle of holes at the height of the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com