Positioning tile laying device for tile laying machine

A brick laying device and brick laying machine technology, which is applied in the direction of construction and building construction, can solve the problems of accurate positioning of difficult tiles, placing them in designated positions, and difficult tiles, achieving accurate positioning, high degree of automation, and easy use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

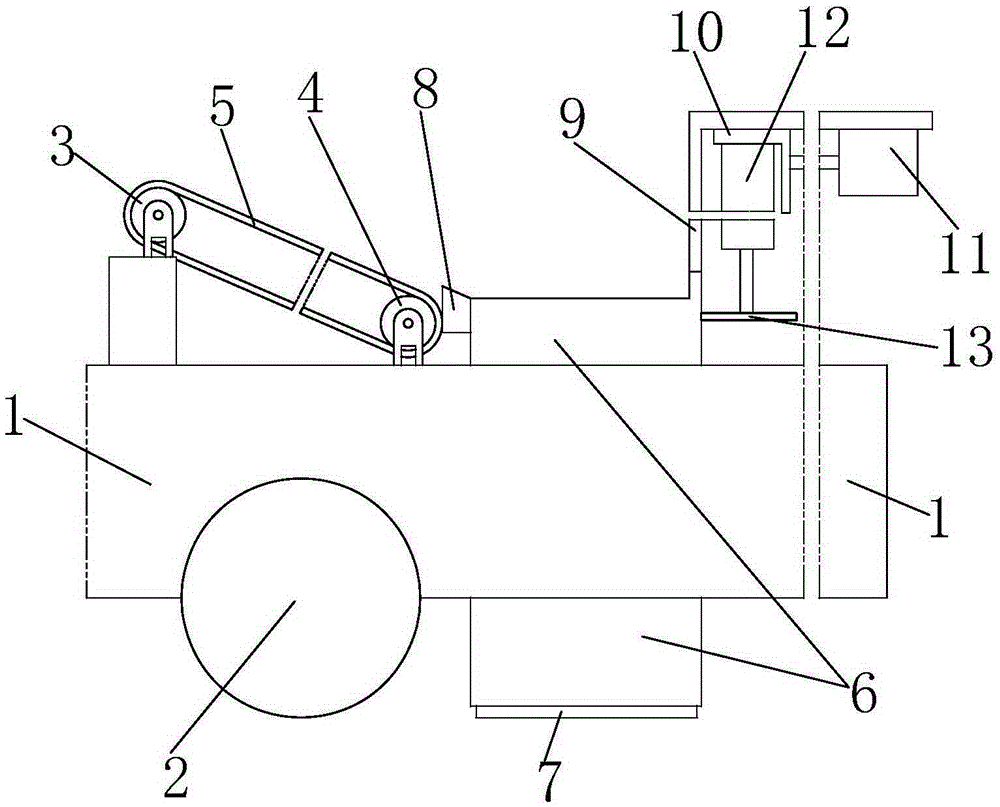

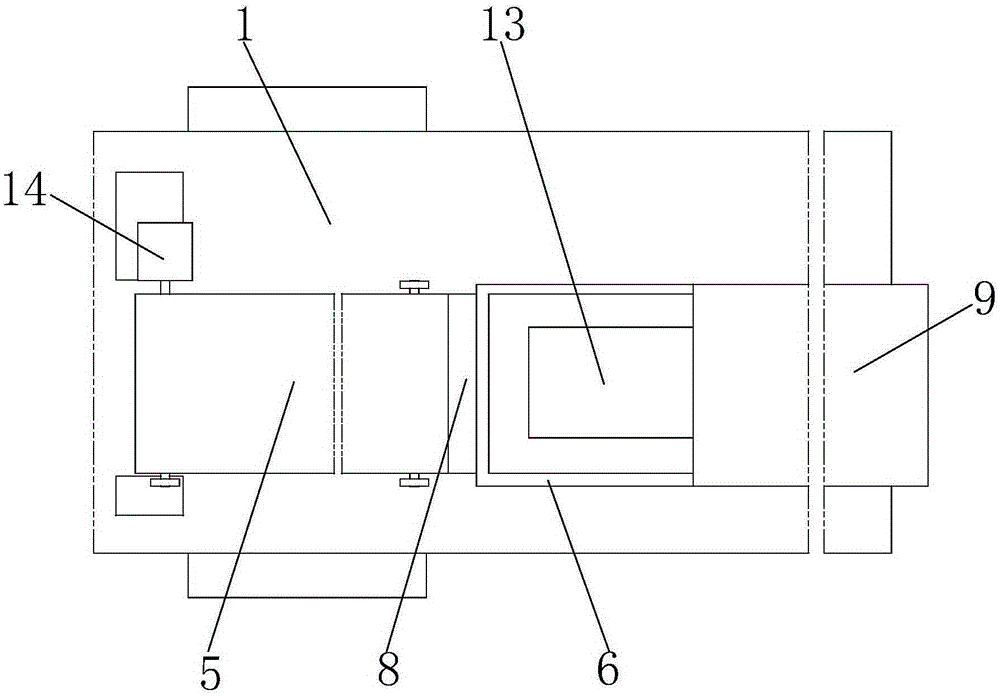

[0018] like Figure 1 to Figure 2 As shown, a positioning brick laying device for a brick laying machine mainly includes a wheel 1 and a car body 2, a No. 1 roller 3 and a No. 2 roller 4 are installed on the car body 2, and the No. 1 roller 3 and the No. 2 roller A belt 5 is connected between the 4, and a motor 14 is connected to the No. 1 roller 3.

[0019] The belt 5 is inclined to the right and down along the horizontal direction, and the right side of the belt 5 is provided with a guide plate cover 6 installed in the car body 2 in a longitudinal sliding manner, and the lower end of the iron cover 6 is fixedly connected with an iron cover 7 , the lower end of the iron sheath 6 is flush with the lower end of the wheel 1, the upper left end of the iron sheath 6 is provided with a bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com