Longitudinal penetrating multiple hydrophilic agent for polyolefin nonwovens

A non-woven fabric, permeable technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of excessive expansion of water, partial conduction obstruction, easy side leakage, etc., to reduce the wetted area and atomic utilization rate. The effect of high and reducing the probability of side leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] raw material:

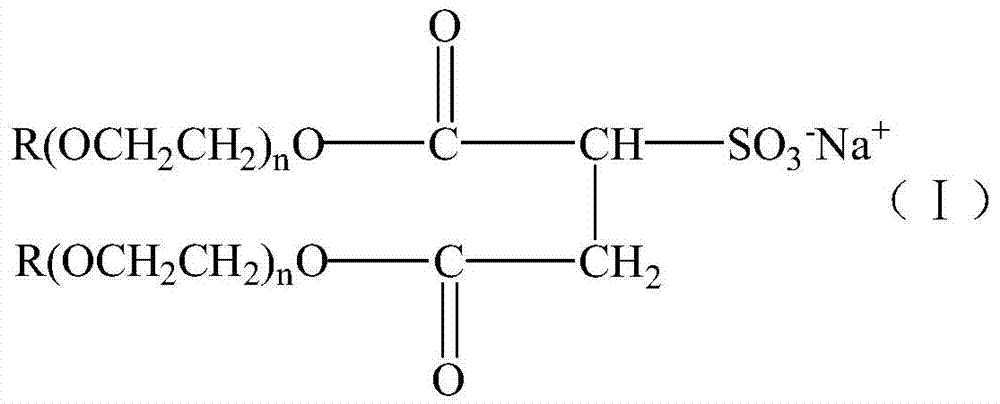

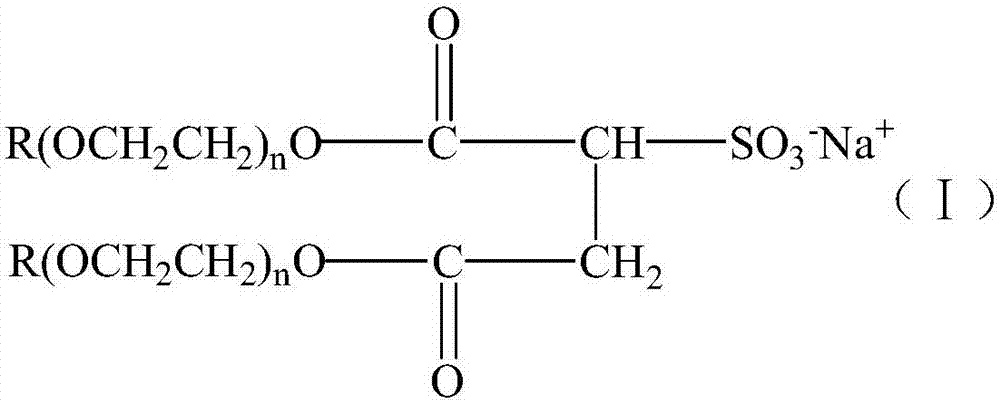

[0040] a. Sodium salt of diisooctyl polyoxyethylene ether (2) sulfosuccinate (content 70%) 38%,

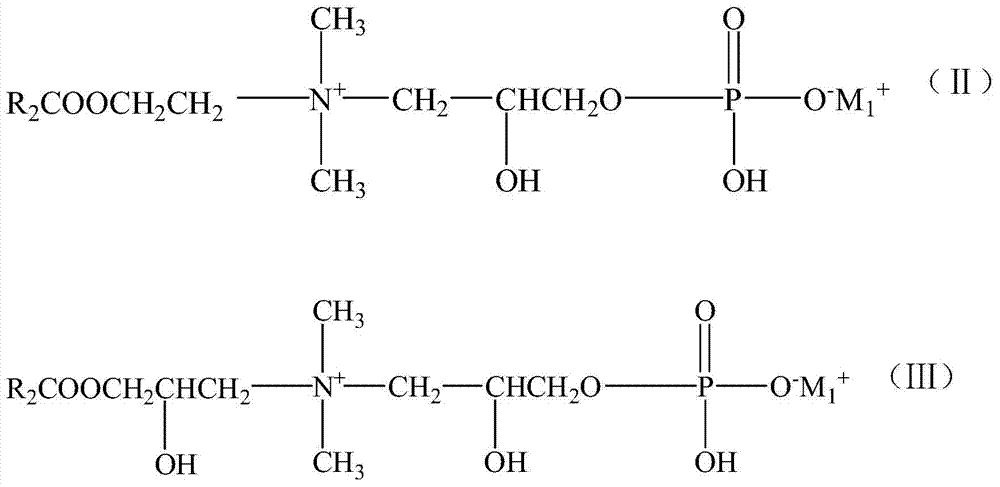

[0041] b.3-{N-(2-lauroyloxyethyl)-N,N-dimethylammonium}-2-hydroxypropyl acid phosphate betaine 7%,

[0042] c. Polyoxyethylene ether (800) oleic acid diester 20%,

[0043] d. Dipolyglycerol diester polyoxyethylene ether (6) 35%.

[0044] Preparation: Add component (a), component (b), component (c) and component (d) in the formula to the reaction kettle in sequence, start stirring and heat up to 50°C, continue stirring for 10 minutes, the kettle liquid is Pale yellow transparent liquid, discharging, filtering and packaging.

Embodiment 2

[0046] raw material:

[0047] a. Maleic acid diisomeric tridecanol polyoxyethylene ether (4) ester sulfonic acid sodium salt (content 70%): 38%,

[0048] b.3-{N-(2-oleoyloxyethyl)-N,N-dimethylammonium}-2-hydroxypropyl acid phosphate betaine: 7%,

[0049] c. Polyoxyethylene ether (600) laurate diester 20%,

[0050] d. Sorbitan diester polyoxyethylene ether (6): 35%.

[0051] Preparation: Add component (a), component (b), component (c) and component (d) in the formula to the reaction kettle in sequence, start stirring and heat up to 50°C, continue stirring for 10 minutes, the kettle liquid is Pale yellow transparent liquid, discharging, filtering and packaging.

[0052] Existing recipe:

[0053] raw material:

[0054] a. Dioctyl sulfosuccinate sodium salt (74%): 40,

[0055] b. Lauryl dimethyl betaine (50%): 20%,

[0056] c. Polyoxyethylene (20) sorbitan monooleate: 20,

[0057] d. Polyether modified silicone oil: 20.

[0058] Preparation: Add component (a), component (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com