Flame-retardant finishing agent and use thereof

A finishing agent and flame retardant technology, which is applied in the field of flame retardant finishing agents, can solve the problems that the flame retardant durability of textiles cannot meet the demand, and achieve the effect of simple and easy processing method, good flame retardant performance, and easy process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

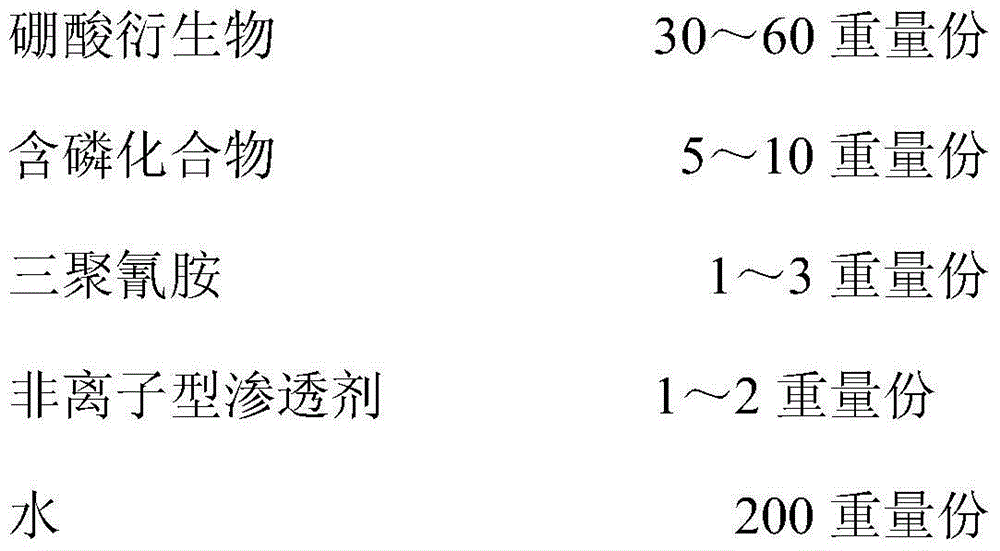

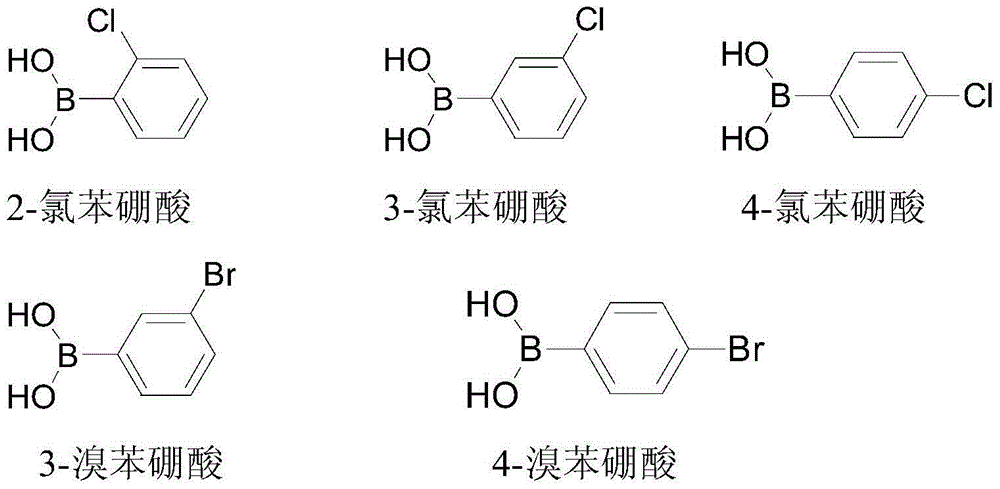

[0033] 1) According to the ratio of 30 parts by weight of 3-chlorophenylboronic acid, 8 parts by weight of amine dihydrogen phosphate, 2 parts by weight of melamine, and 1.5 parts by weight of penetrant JFC, mix the components, add 200 parts by weight of water, stir for 10 minutes, and then Ultrasound for 15 minutes, and stand still to obtain a highly flame-retardant finishing agent;

[0034] 2) Use acetic acid to adjust the finishing agent to a pH of 4.5, put the textile into a highly flame-retardant finishing agent at 40°C (bath ratio 1:60, dipping and shaking for 15 minutes, then dipping and rolling twice, and the excess rate is 70% , pre-baked at 80°C for 8 minutes, then baked at 160°C for 5 minutes, ultrasonically washed 5 times, and dried to obtain a high flame-retardant fabric. Samples were taken for flame-retardant performance testing, and the test results are shown in the table below:

[0035]

[0036] It can be seen from the above table that when the above ratio a...

Embodiment 2

[0038] 1) According to the ratio of 30 parts by weight of 3-bromophenylboronic acid, 8 parts by weight of ammonium dihydrogen phosphate, 2 parts by weight of melamine, and 1.5 parts by weight of penetrant JFC, mix the components, add 200 parts by weight of water, stir for 10 minutes, and then Ultrasound for 15 minutes, and stand still to obtain a highly flame-retardant finishing agent;

[0039] 2) Use acetic acid to adjust the finishing agent to a pH of 4.5, put the textile into a highly flame-retardant finishing agent at 40°C (bath ratio 1:60, dipping and shaking for 15 minutes, then dipping and rolling twice, and the excess rate is 70% , pre-baked at 80°C for 8 minutes, then baked at 160°C for 5 minutes, ultrasonically washed 5 times, and dried to obtain a high flame-retardant fabric. Samples were taken for flame-retardant performance testing, and the test results are shown in the table below:

[0040]

[0041] It can be seen from the above table that when the above ratio...

Embodiment 3

[0043] 1) According to the ratio of 50 parts by weight of 3-chlorophenylboronic acid, 8 parts by weight of amine dihydrogen phosphate, 2 parts by weight of melamine, and 1.5 parts by weight of penetrant JFC, mix the components, add 200 parts by weight of water, stir for 10 minutes, and then Ultrasound for 15 minutes, and stand still to obtain a highly flame-retardant finishing agent;

[0044] 2) Use acetic acid to adjust the finishing agent to a pH of 4.5, put the textile into a highly flame-retardant finishing agent at 40°C (bath ratio 1:60, dipping and shaking for 15 minutes, then dipping and rolling twice, and the excess rate is 70% , pre-baked at 80°C for 8 minutes, then baked at 160°C for 5 minutes, ultrasonically washed 5 times, and dried to obtain a high flame-retardant fabric. Samples were taken for flame-retardant performance testing, and the test results are shown in the table below:

[0045]

[0046] It can be seen from the above table that when the above ratios ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com