Pipe continuous cutting method

A cutting method and pipe technology, applied in the direction of tubular objects, applications, laser welding equipment, etc., can solve the problems of decreased processing efficiency of CNC laser cutting machines, and achieve the effects of saving processing time, reducing feeding times, and improving feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

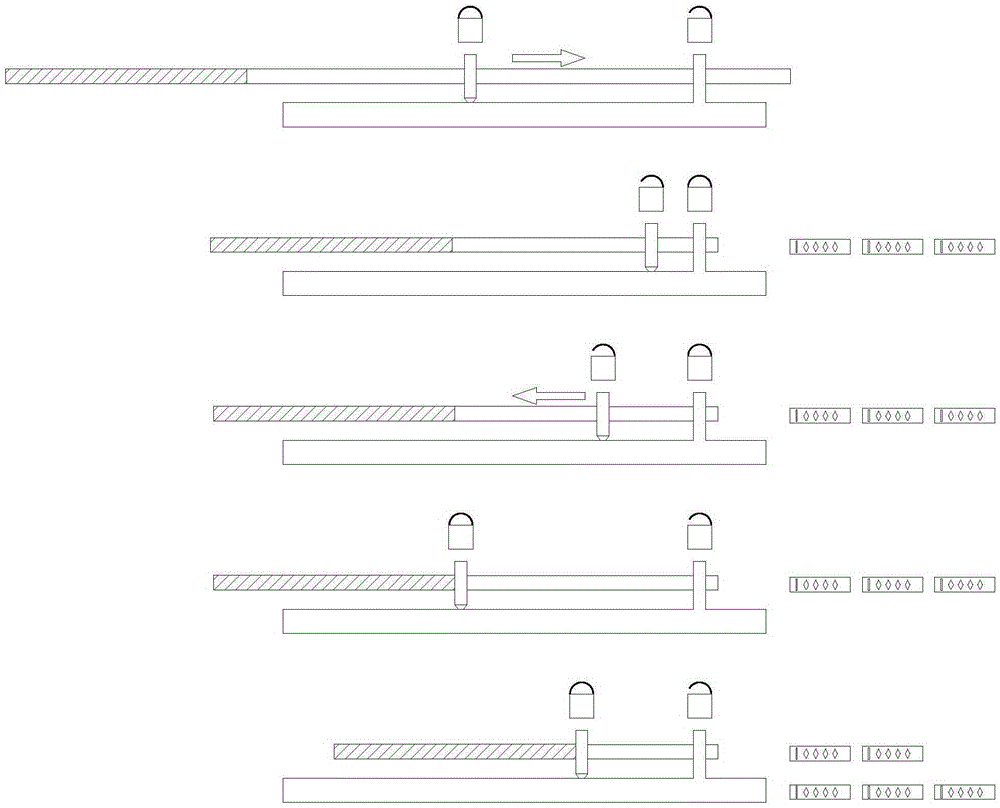

[0017] The present invention will be further described below according to the accompanying drawings.

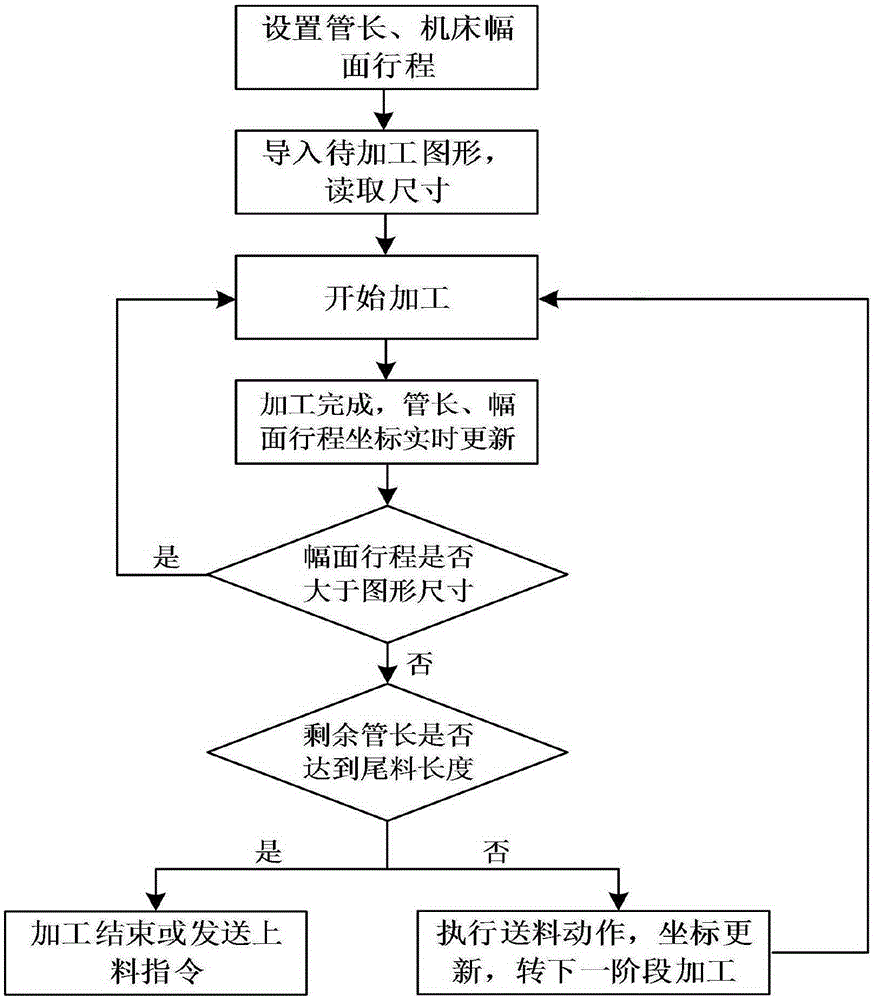

[0018] Such as figure 1 As shown, first start the processing software of the laser cutting machine, and set the length of the pipe and the stroke of the machine tool width in the software, and then import the size data of the graphics into the processing software according to the graphics to be processed.

[0019] Start processing. During the processing, the cutting direction Y of the pipe axis increases, the part coordinate P increases, the feed length LengthFeeded remains unchanged, the cutting head coordinate FirstHeadDist remains unchanged, and the remaining length of the pipe to be processed decreases. At the same time, during the processing, the coordinates change in real time , but equation (1) maintains the balance:

[0020] Y+LengthFeeded=P+FirstHeadDist formula (1);

[0021] After the processing is completed, judge the relationship between the remaining stroke of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com