Gear grinding running-in and extruding type feed grinder

An extrusion and pulverizer technology, applied in feed, food science, application and other directions, can solve the problems of long processing cycle of raw materials, high labor intensity, complex structure, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

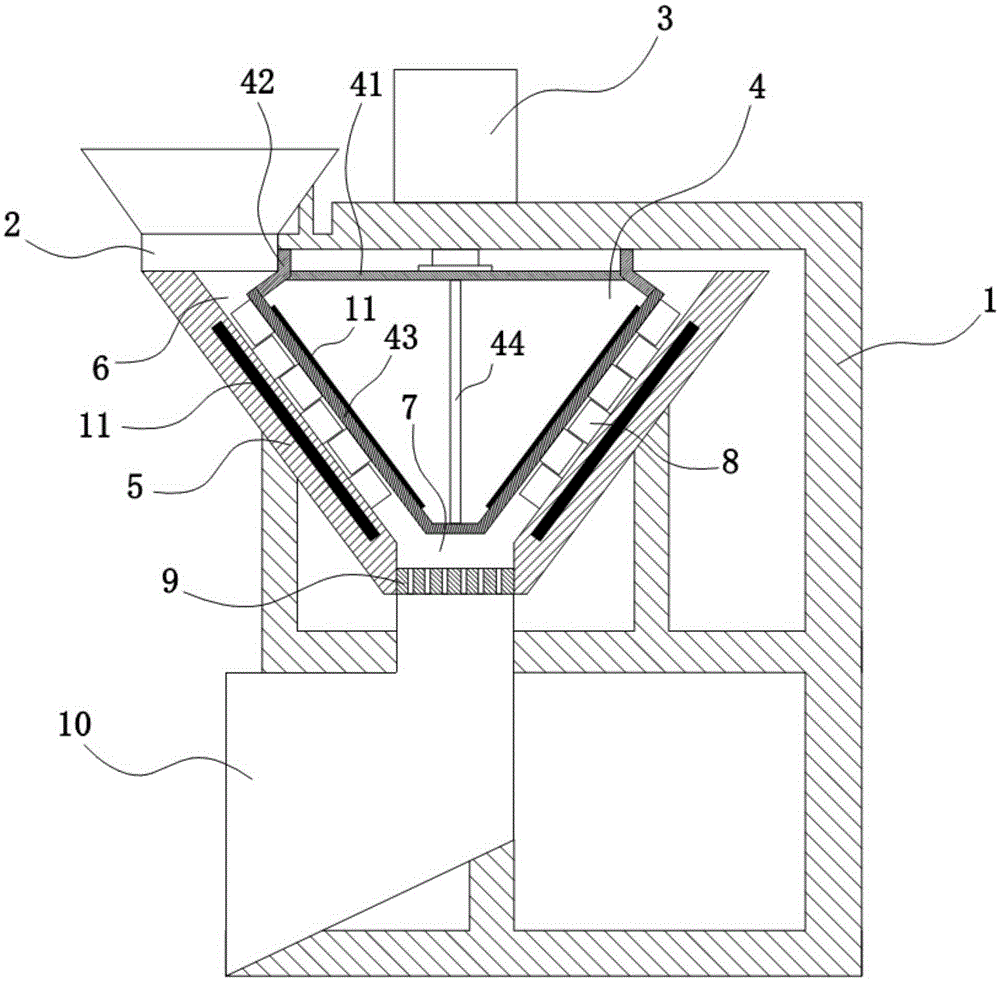

[0011] Such as figure 1 As shown, the grinding-tooth grinding-in extrusion type feed grinder of the present embodiment comprises a feed hopper 2 installed on a frame 1, a discharge hopper 10, a motor 3 and a grinding and mixing device, and the grinding and mixing device includes a motor driven by the motor 3. The inner grinding shell 4 and the outer grinding barrel 5 installed on the periphery of the inner grinding shell 4, the outer grinding barrel 5 is installed on the frame 1; the inner grinding shell 4 includes a cover plate 41 fixedly connected with the drive shaft of the motor 3, and a The connecting ring 42 is fixedly connected to the grinding sleeve 43 with the cover plate 41, and a reinforcing rod 44 is installed between the lower end of the grinding sleeve 43 and the cover plate 41; The inner wall of the outer grinding barrel 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com