Tobacco products that can be heated by induction

A technology for tobacco products and tobacco, which is applied in the fields of tobacco, tobacco processing, and tobacco preparation, and can solve problems such as the scheme for heating tobacco molded parts that has not been proposed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

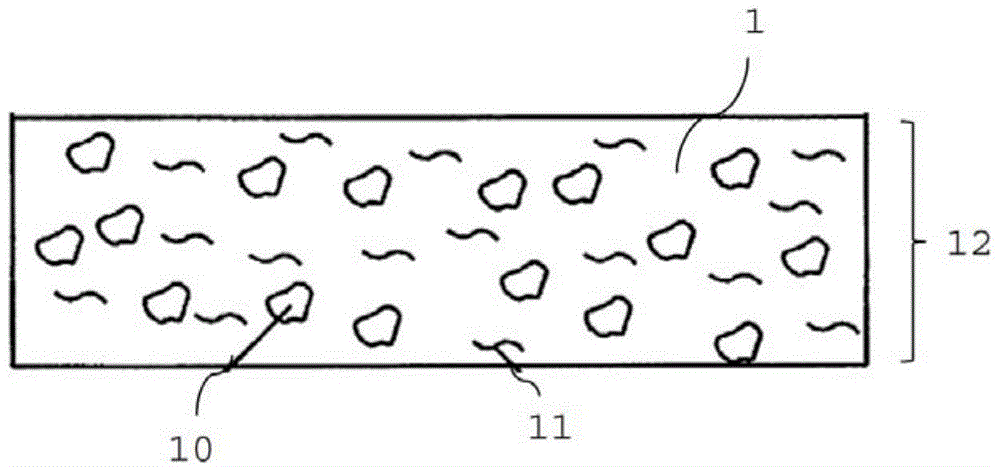

[0043] figure 1 An aerosol-forming substrate in the form of a tobacco sheet 1 is schematically shown. The tobacco sheet is made of homogeneous tobacco particles 11 and is preferably a molded leaf as defined above and contains susceptor particles 10 .

[0044] The thickness 12 of the tobacco sheet is preferably between 0.8 mm and 1.5 mm, while the size of the susceptor particles is preferably between 10 microns and 80 microns. To form a tobacco product according to the invention, a tobacco sheet 1 is crimped and folded to form a tobacco rod. This continuous rod is then cut to size for use in tobacco plugs for use in conjunction with induction heating means for aerosol generation.

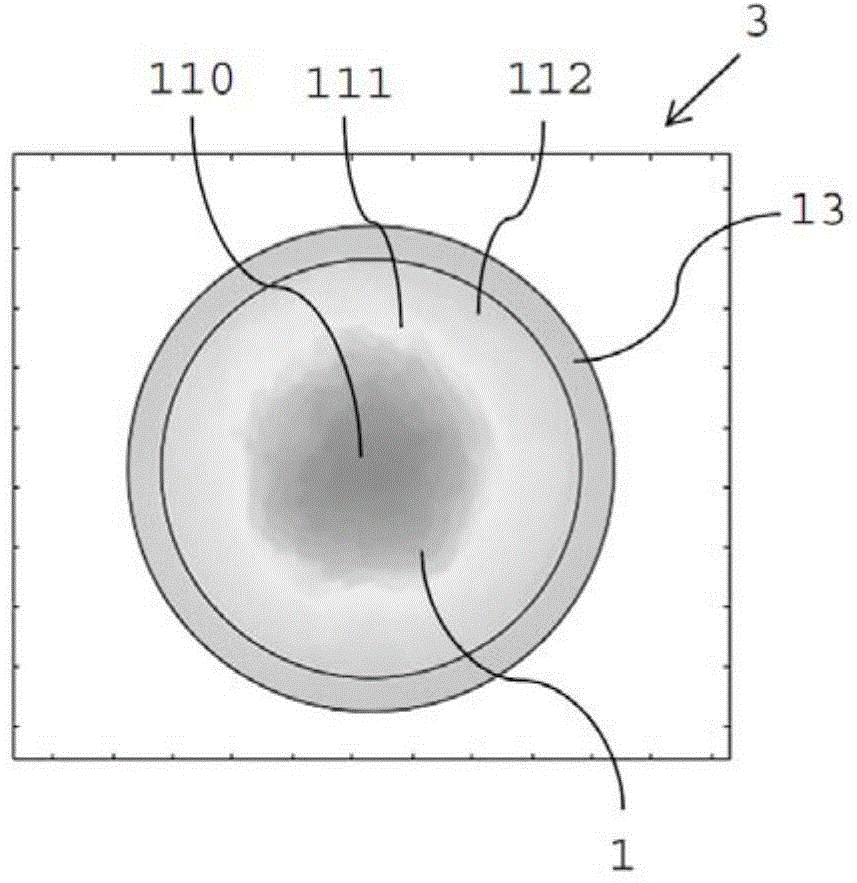

[0045] figure 2 A view showing a simulated temperature distribution of a cross-section of a cylindrical tobacco plug 2 heated by a heating blade 20 . The tobacco plug comprises an aerosol-forming substrate made from crimped tobacco sheet comprising homogenized tobacco material and glycerin as an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com