Inductively heatable tobacco product

A technology for tobacco products and induction heating, which is applied in the fields of tobacco, tobacco processing, and tobacco preparation, and can solve problems such as the scheme for heating tobacco molded parts that has not been proposed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

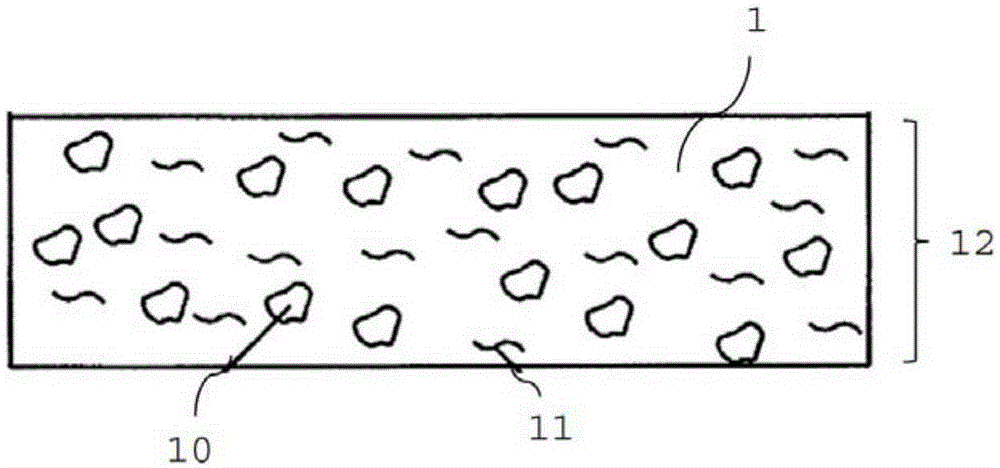

[0043] figure 1 The aerosol-forming substrate in the form of a tobacco sheet 1 is schematically shown. The tobacco sheet is made of homogeneous tobacco particles 11 and is preferably a cast leaf as defined above and contains susceptor particles 10.

[0044] The thickness 12 of the tobacco sheet is preferably between 0.8 mm and 1.5 mm, and the size of the susceptor particles is preferably between 10 microns and 80 microns. To form the tobacco product according to the present invention, the tobacco sheet 1 is crimped and folded to form a tobacco rod. This continuous rod is then cut to the required size for use in combination with induction heating devices to generate aerosol shaped tobacco pieces.

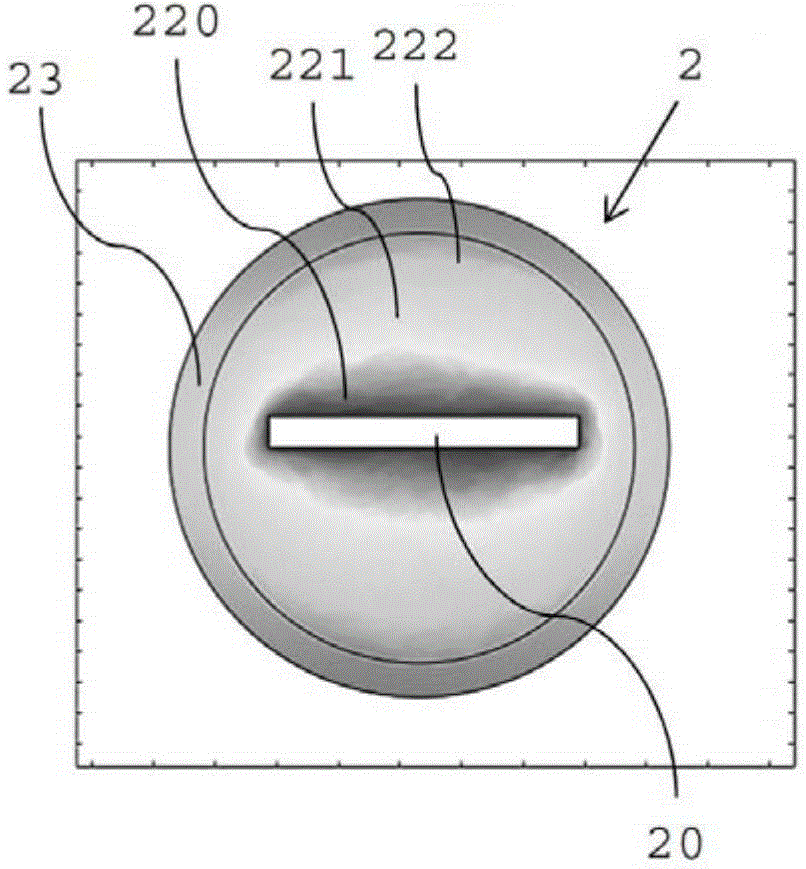

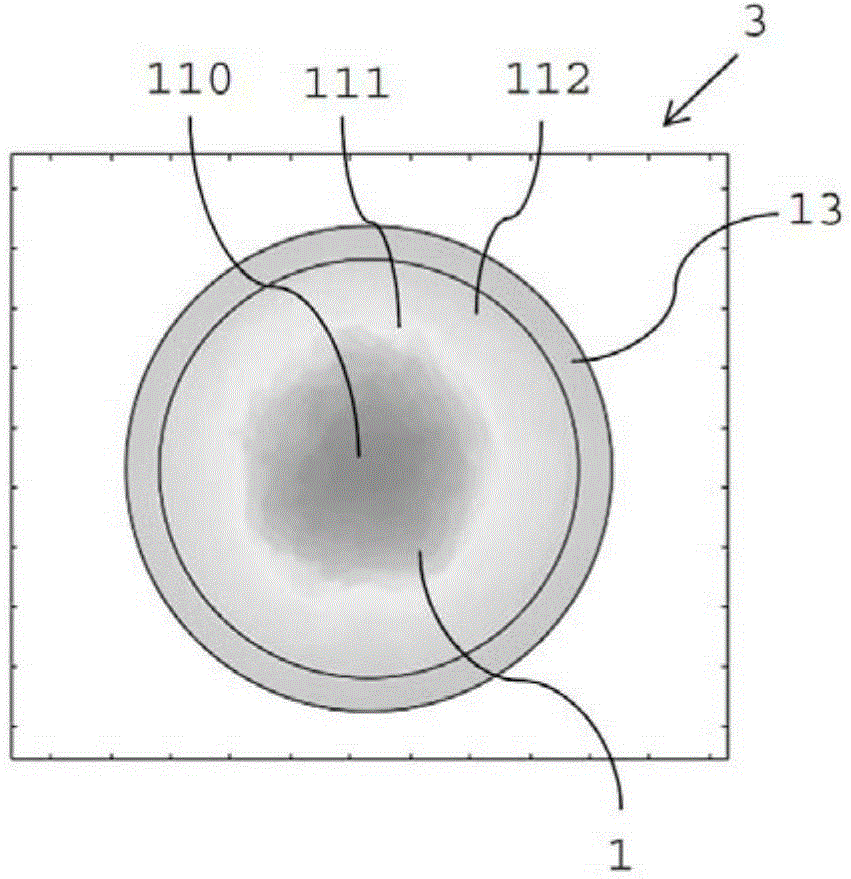

[0045] figure 2 A view showing the simulated temperature distribution of the cross section of the cylindrical tobacco molded article 2 heated by the heating blade 20. The tobacco molding includes an aerosol-forming substrate made of a rolled tobacco sheet containing a homogeneous tobac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com