A zero entrainment friction and wear testing machine

A wear test and test piece technology, applied in the direction of testing wear resistance, etc., can solve problems such as no, and achieve the effect of compensating for displacement error, improving load stability, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

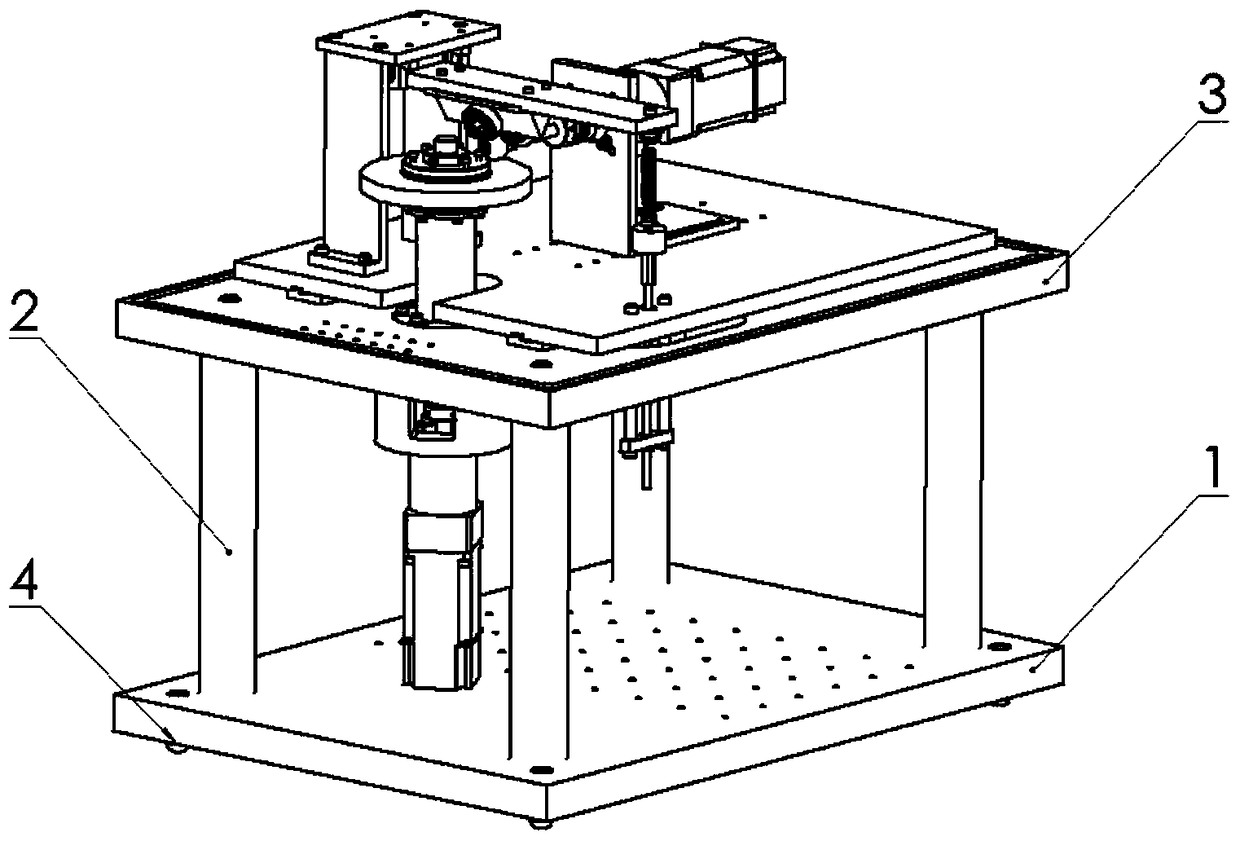

[0033] This example figure 1As shown, the zero entrainment friction and wear testing machine of this embodiment, the test bench includes a base, a loading device, a drive system and two sets of independent motion systems.

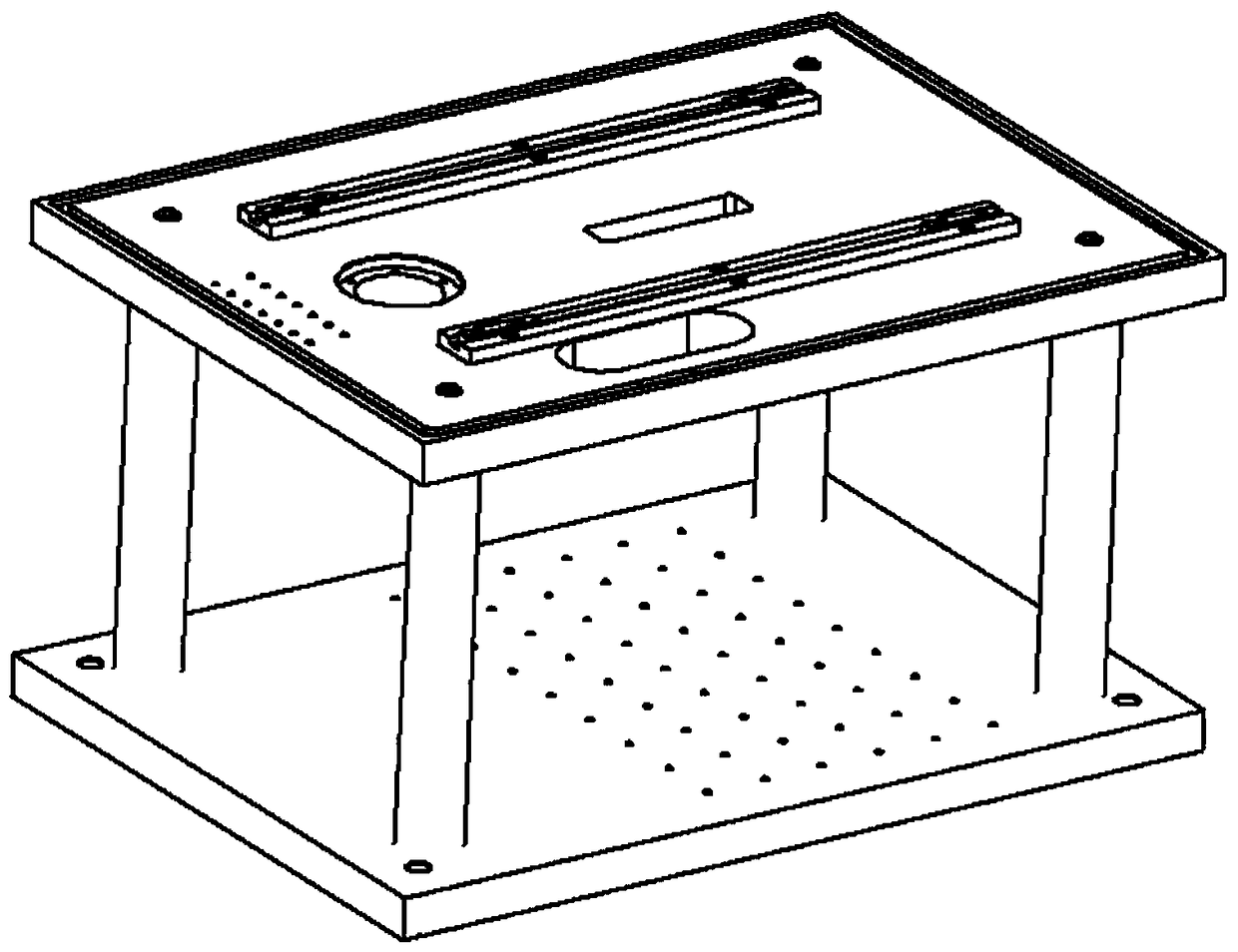

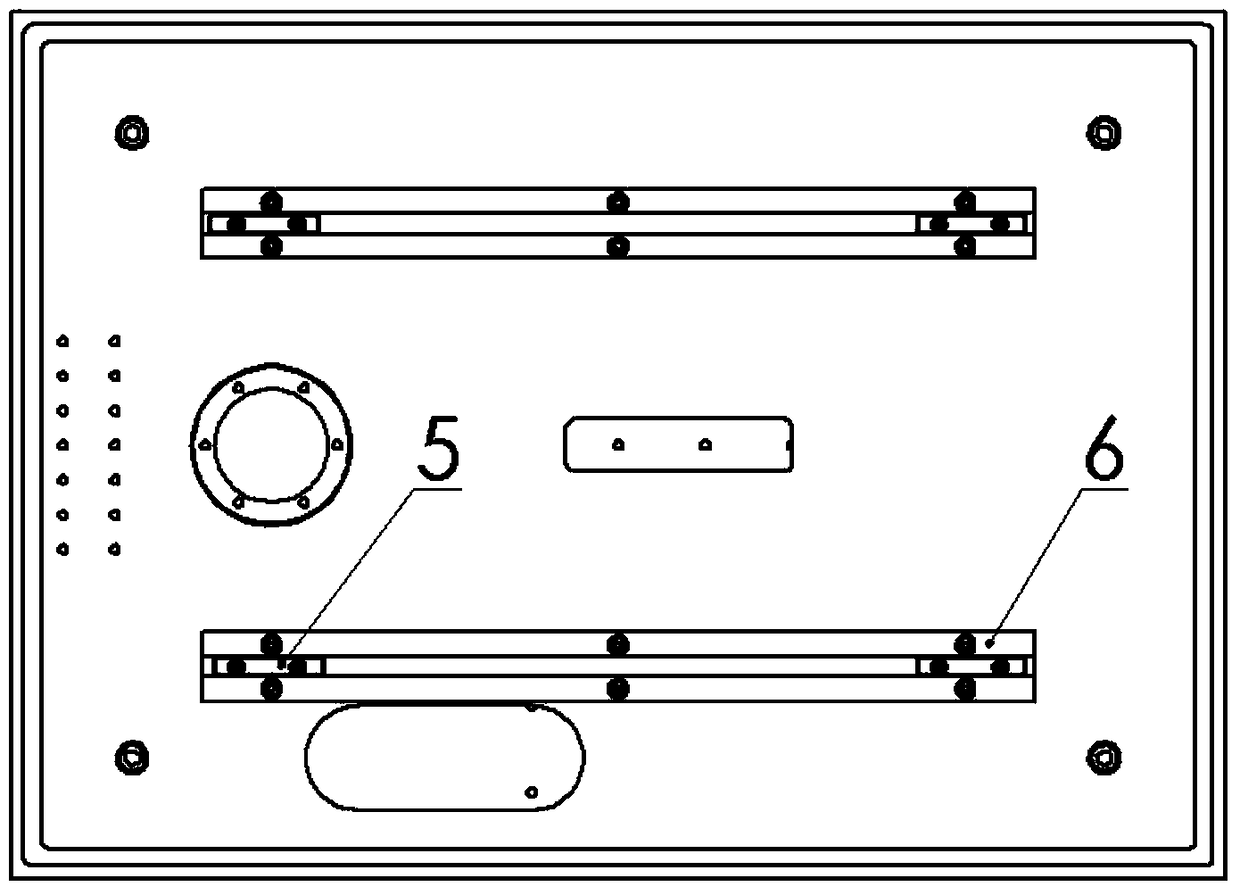

[0034] Such as figure 2 As shown, the composition of the base is as follows: four support screws 4 are fixed on the lower base plate 1, one end of the four pillars 2 is fixed on the lower base plate 1 with screws, the other end supports the upper table 3 and is fastened with screws, and the guide rail 6 is fixed with screws. On the table top 3, the inside is inlaid with a screw key 5, and the key 5 cooperates with the operation panel 46.

[0035] Such as Figure 6 , as shown in 7, the composition of the motion system is: System 1: the servo motor 30 and the reducer 29 are connected by threads, the reducer 29 and the reducer support frame 28 are connected by threads, and there is a rubber pad in the middle, and the reducer support frame 28 is used Screws...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com