Method for preventing TEM (Transmission Electron Microscope) chip sample from being cracked

A sample and chip technology, which is applied in the field of preventing TEM chip samples from cracking, can solve the problems of low success rate, high cost, and low productivity, and achieve the effect of avoiding the curtain effect and improving the success rate of sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

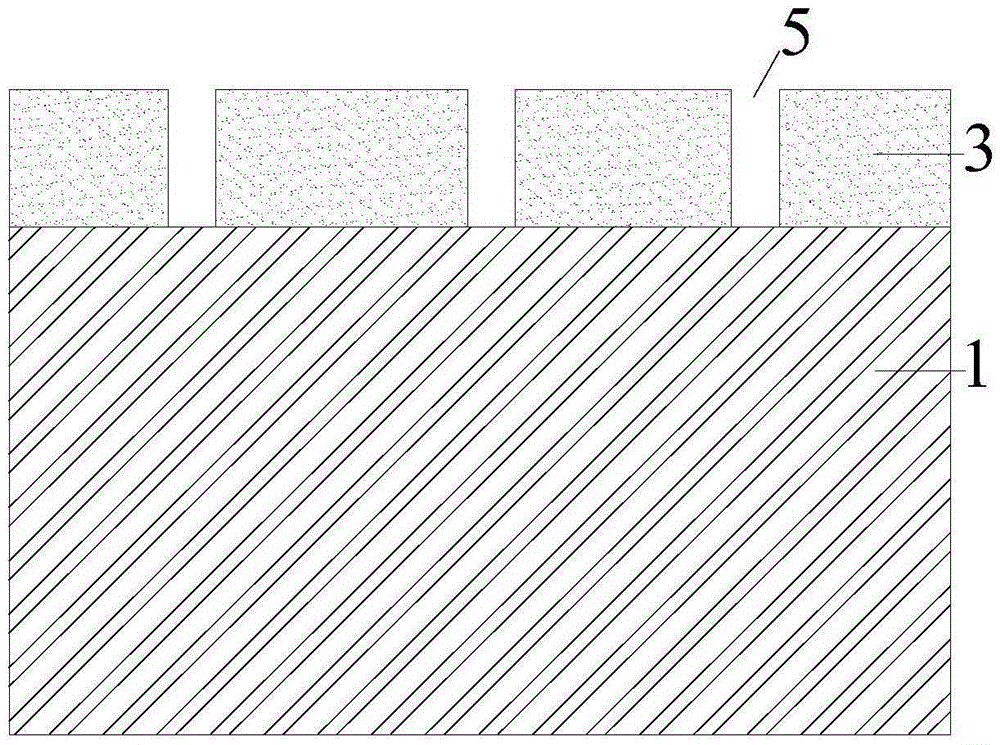

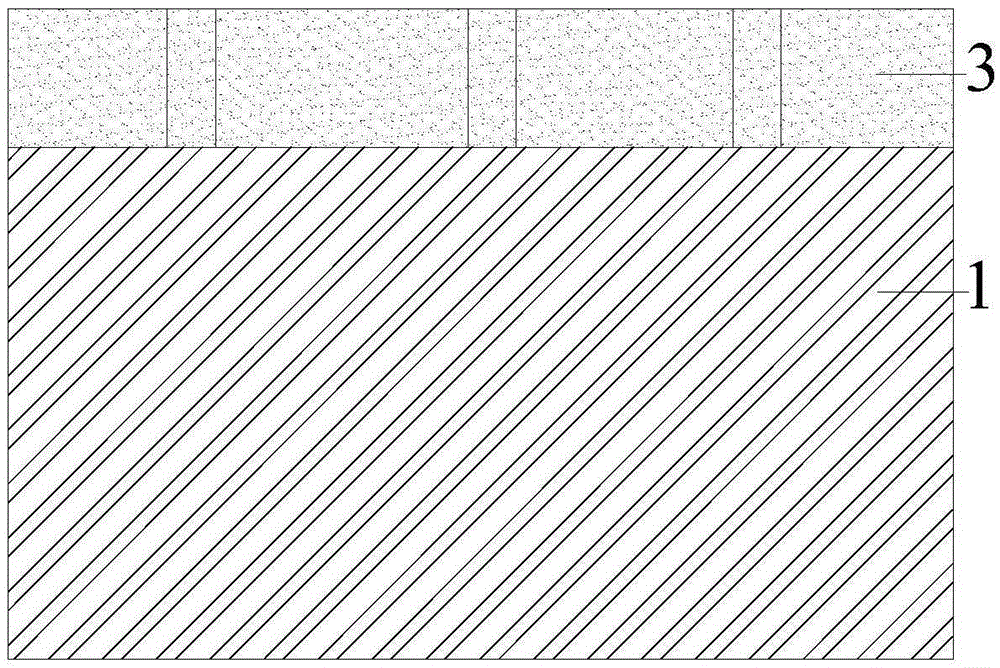

[0031] Please refer to Figure 5 , the invention provides a kind of method that prevents TEM chip sample from cracking, comprises the following steps:

[0032] Step 1: Provide the chip 1, and define the non-observation area and the observation area. In this embodiment, the non-observation area may be the circuit layer or the replacement layer where the gate is located.

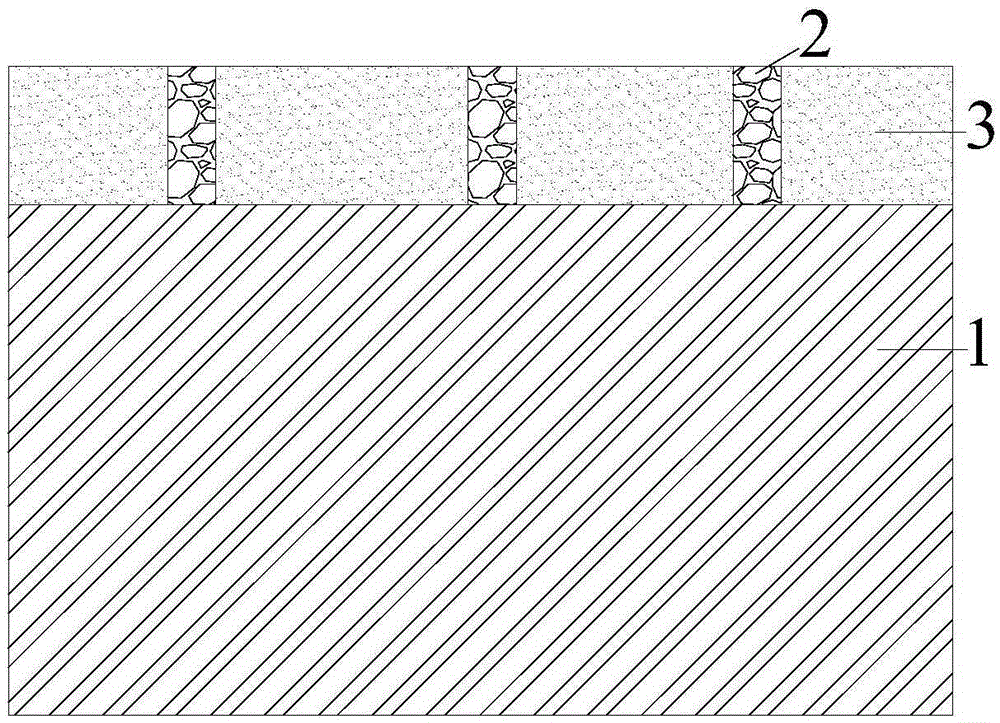

[0033] Step 2: Please refer to figure 1 , in the non-observation area, the replacement layer that needs to be replaced is exposed, and the replacement layer can be ground to the replacement layer by chemical mechanical polishing process, or it can be cut first and then used chemical mechanical polishing process to expose the replacement layer, and the replacement laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com