Multi-point support welding line fast detection process for various kinds of electronic tubes

A technology of electronic pipe fittings and multi-point support, which is applied in the direction of liquid tightness measurement using liquid/vacuum, and can solve the problems of unsuitable electronic pipe fittings detection, low efficiency, and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

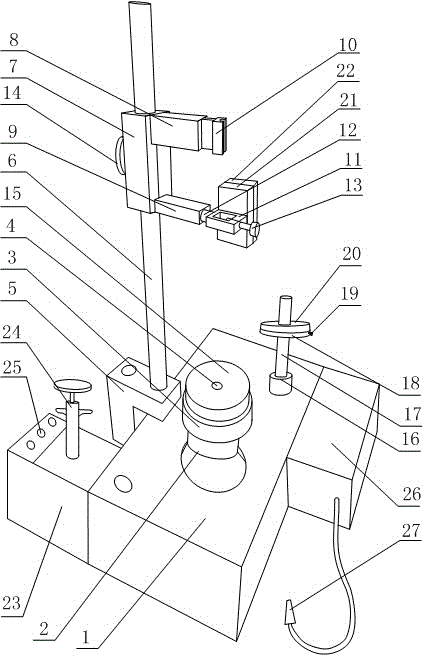

[0025] Such as figure 1 As shown in the figure, a rapid detection process of welding seams supported by multiple points of various electronic pipe fittings includes a vacuum detection platform 1, on which a detection panel 3 is connected through a closed telescopic opening 2, and on the detection panel 3 A layer of rubber pad 15 is arranged on the rubber pad 15 and the detection plate surface 3 is provided with an air extraction hole 4 communicating with the internal vacuum of the vacuum detection table 1; A support rod 6 is provided, and a fixed body 7 that can move up and down along the support rod 6 is installed on the support rod 6. The fixed body 7 is installed on the support rod 6 through a fastening knob 14; The upper cross arm 8 and a lower cross arm 9 are provided with a guide block 10 on the upper cross arm 8, a guide groove is provided on the guide block 10, and a clamping mechanism is connected on the lower cross arm 9: including a rectangular frame body 11, a fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com