Small-sized compression refrigerating system based on micro-channel heat exchanger

A micro-channel heat exchanger and compression refrigeration technology, applied in irreversible cycle compressors, refrigerators, compressors, etc., can solve the problems of cooling electronic components below ambient temperature, low efficiency, large volume, etc. , to achieve the effect of eliminating fans, compact size, and low cooling resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

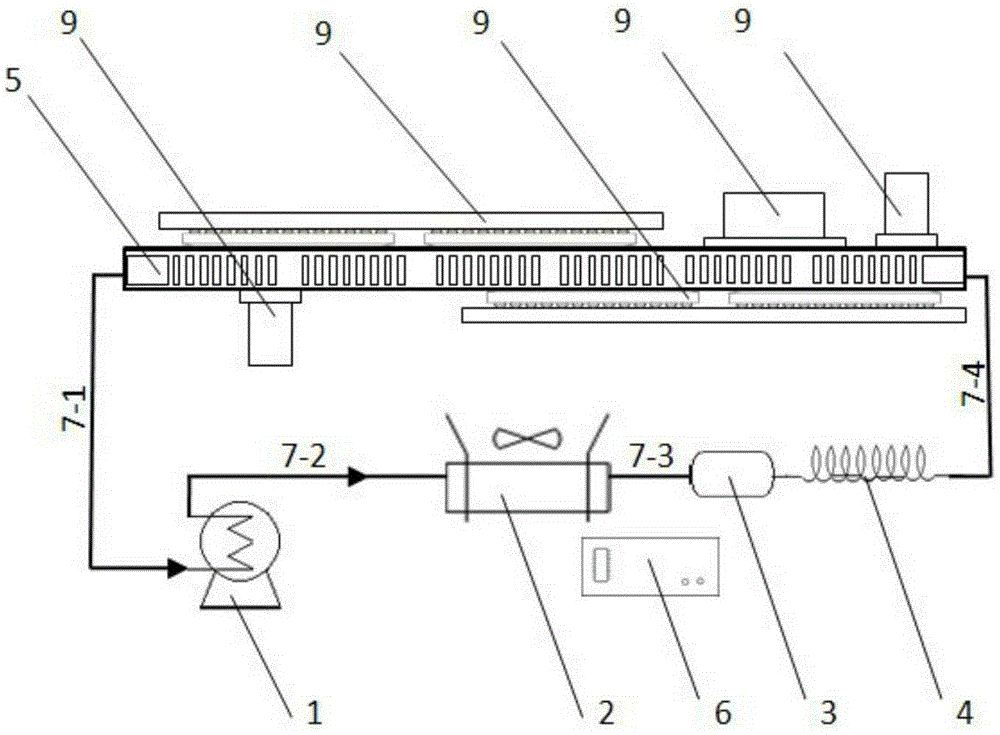

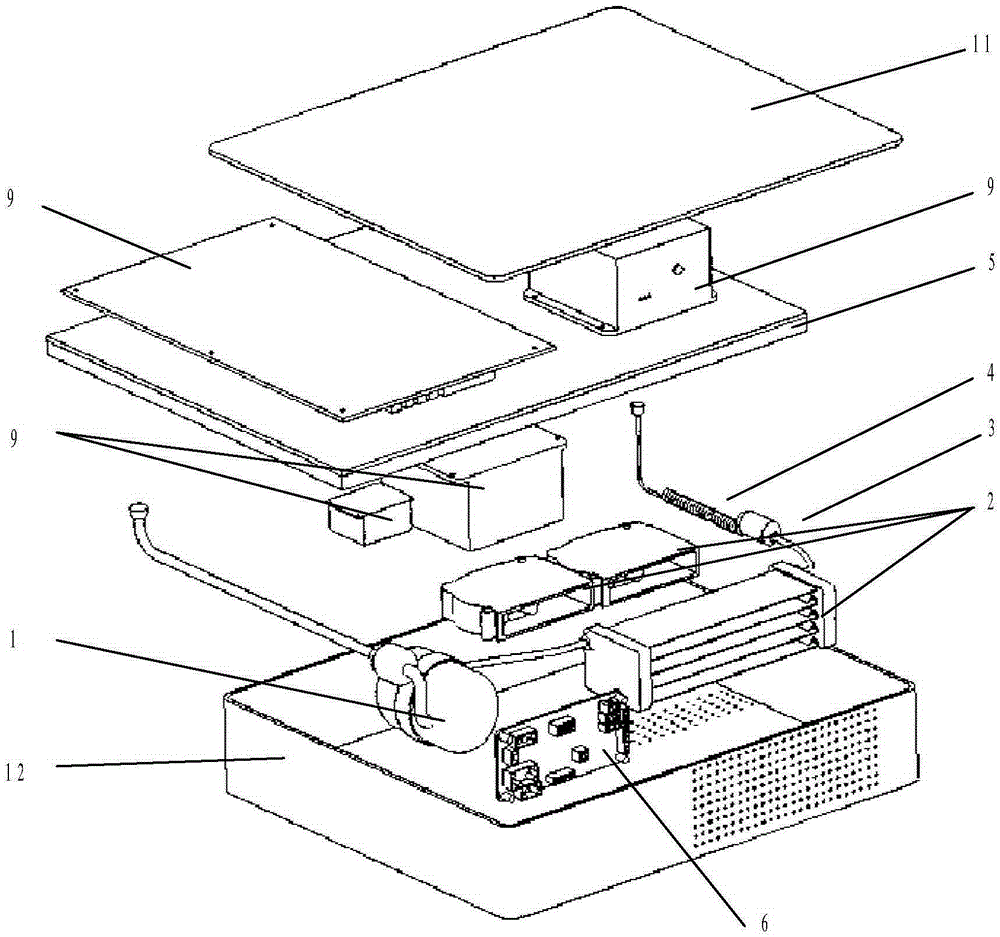

[0023] The invention discloses a small compression refrigeration system based on a micro-channel heat exchanger, the schematic diagram of which is as follows figure 1 As shown, the compression refrigeration cycle consists of: 1. compressor, 2. condenser, 3. filter drier, 4. capillary tube, 5. microchannel heat exchanger, 6. main control board, 7. connecting pipeline (by 7 -1, 7-2, 7-3, 7-4 composed of four pipelines), the detailed connection relationship see figure 1 , forming a sealed and closed pipeline circuit, filled with a certain quality of refrigerant 8 inside, to dissipate heat from the heating electronic components 9 in the electronic equipment.

[0024] The main working principle is: the refrigerant 8 (refrigerant) is driven by the compressor 1, flows in the above-mentioned pipeline circuit, and performs the thermal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com