Easy-to-clean heat exchange coil type high-efficiency heating furnace

A heating furnace and high-temperature heating technology, which is used in the chemical industry, civil heating furnaces, and petroleum fields, can solve the problems of short service life of heat exchange coils, cumbersome cleaning operations, and poor cleaning effects, and achieves improved cleaning efficiency and convenience. Excellent effect of cleaning operation and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

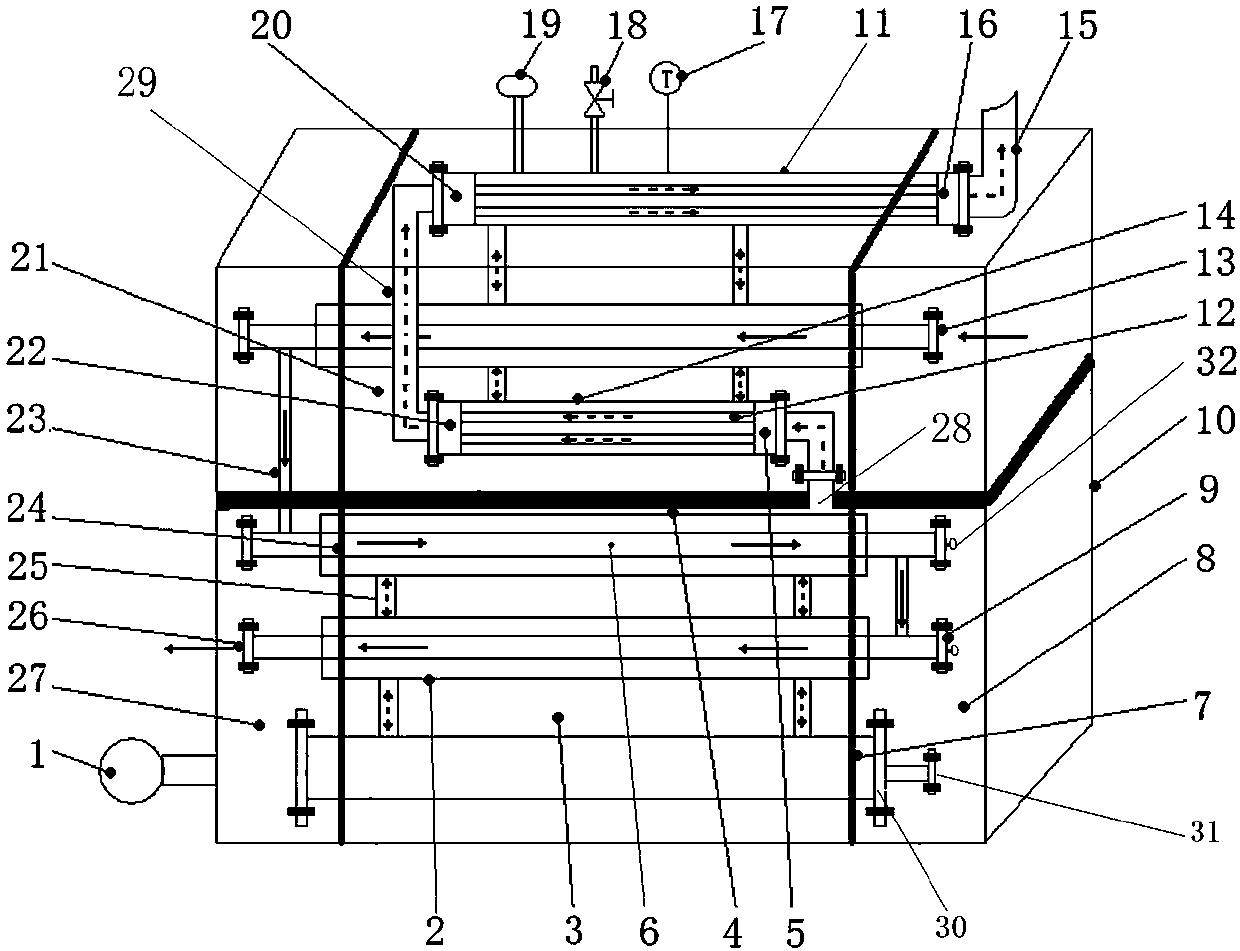

[0037] see figure 1 , a heating furnace equipped with heat exchange coils that are easy to clean. The heat exchange coils of this heating furnace adopt a horizontal layout (vertical layout can also be used according to actual needs), which includes a square furnace body, and the furnace body passes through The interval between the transverse partitions 4 is an upper heating furnace body 21 (i.e. a low-temperature heating furnace body) and a lower heating furnace body 10 (i.e. a high-temperature heating furnace body), and the lower heating furnace body 10 is separated by a left pyrotechnic shielding plate 24 and a right pyrotechnic shielding plate 7 It is the central combustion chamber 3 and the left descaling chamber 27 and the right descaling chamber 8 on both sides, and the descaling chambers are all provided with openable doors.

[0038] The structure of the flue gas system is described below: the combustion chamber 3 is connected to the burner 1 outside the furnace body, t...

Embodiment 2

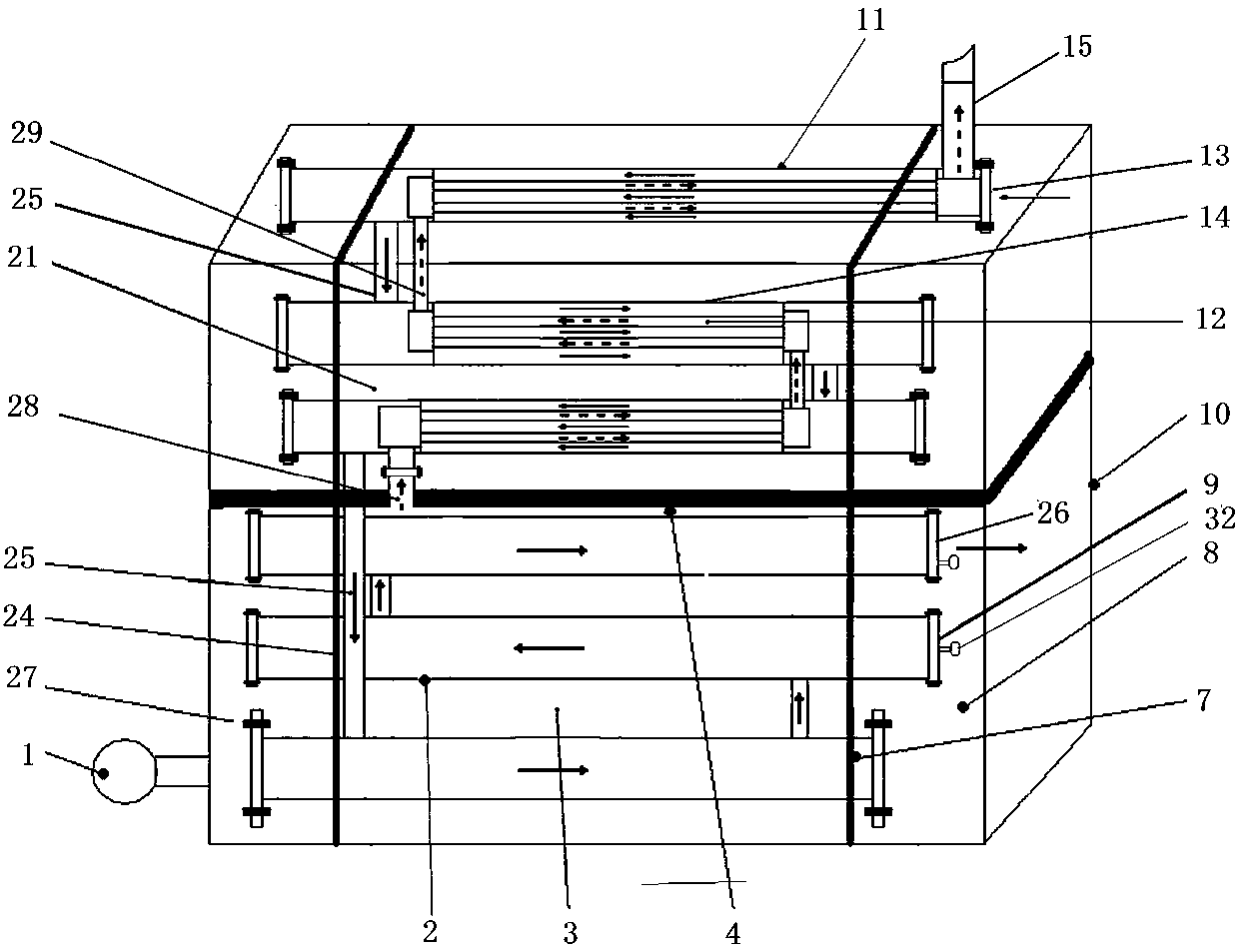

[0047] see figure 2 , a heating furnace installed with heat exchange coils that are easy to clean. The heat exchange coils of this heating furnace adopt a horizontal layout (or a vertical layout according to needs), which includes a square furnace body, and the furnace body passes through the horizontal layout. The partition plate 4 is separated by an upper heating furnace body 21 (i.e. a low-temperature heating furnace body) and a lower heating furnace body 10 (i.e. a high-temperature heating furnace body), and the lower heating furnace body 10 passes through the left pyrotechnic shielding plate 24 and the right pyrotechnic shielding plate 7. The combustion chamber 3 in the center and the left descaling chamber 27 and the right descaling chamber 8 on both sides, and the descaling chambers are all provided with openable doors.

[0048] The lower heating furnace body 10 is connected to the burner 1, and the transverse partition plate 4 is provided with a smoke outlet 28 to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com