A cut-off valve applied to silicone pipeline

A technology for shutting off valves and pipes, applied in valve details, valve devices, engine components, etc., can solve the problems of large influence of flow and pressure, high manufacturing cost, complex structure, etc., to save production costs, control circulation or cut off convenient. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

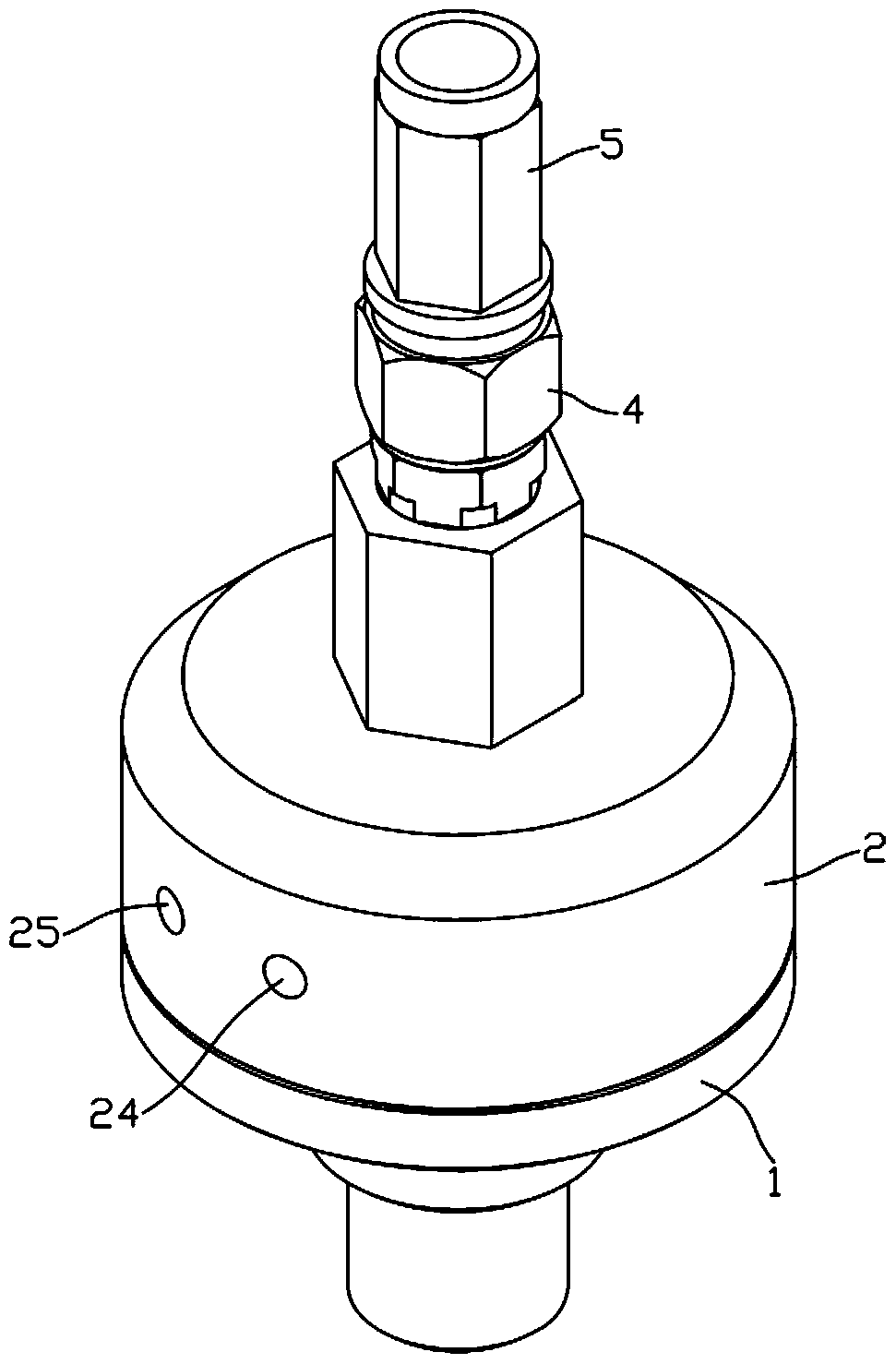

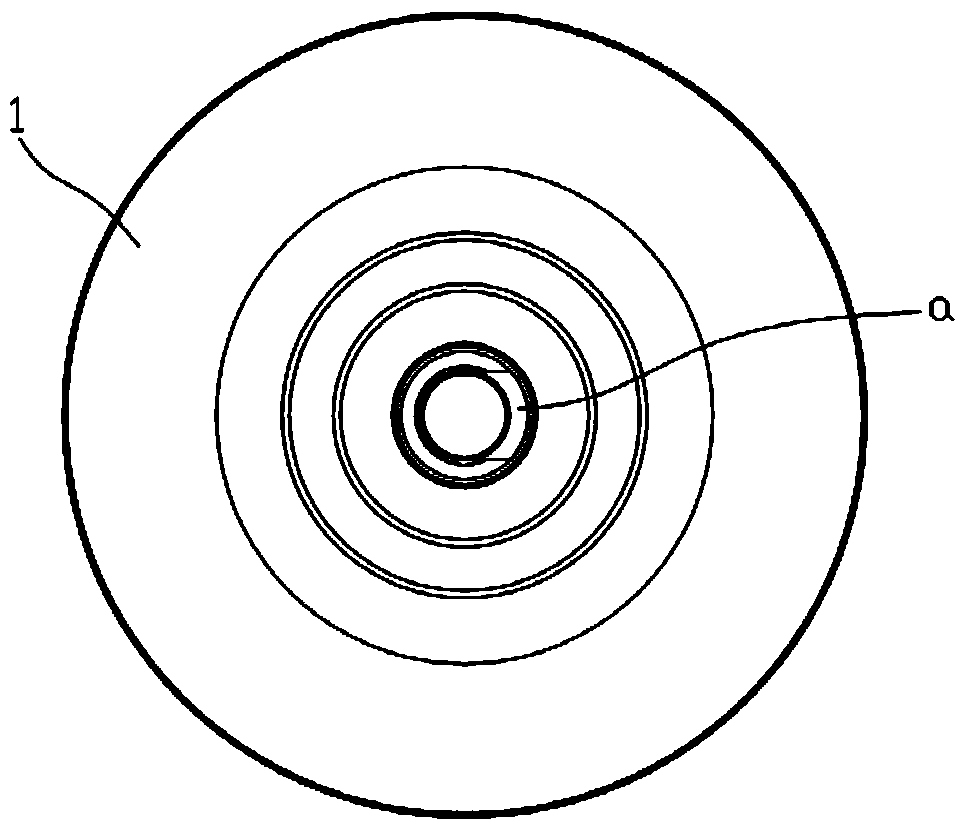

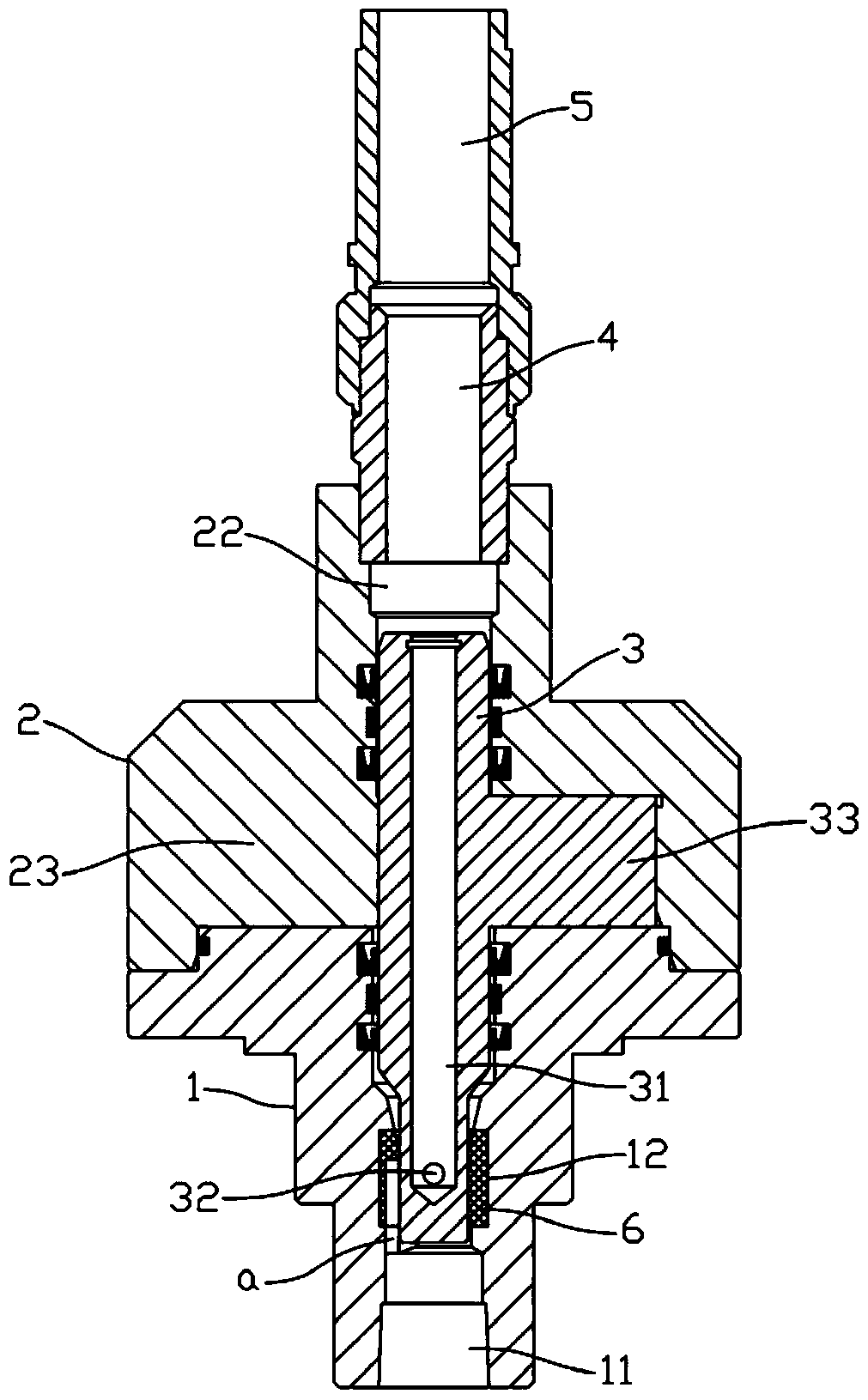

[0019] Example: see Figures 1 to 5 As shown, a cut-off valve applied to a silicone pipeline includes a valve seat 1, a valve sleeve 2 and a valve core 3. A cavity 21 is formed on the valve sleeve 2, and a discharge hole 22 is formed on the bottom surface of the cavity 21. The valve The sleeve 2 is screwed on the valve seat 1, and the valve seat 1 is formed with a feed hole 11, and the two ends of the valve core 3 are respectively inserted into the discharge hole 22 of the valve sleeve 2 and the feed hole 11 of the valve seat 1, A ring groove 12 is formed on the inner wall of the feed hole 11 of the valve seat 1, and an elastic sleeve 6 is inserted and fixed in the ring groove 12. The lower end of the valve core 3 is inserted into the elastic sleeve 6, and a penetrating valve core 3 The channel 31 on the top surface, the inner wall of the bottom end of the channel 31 is formed with a through hole 32 penetrating through the outer wall of the valve core 3, the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com