Air filter

A technology of air filter and air outlet, which is applied in combustion air/combustion-air treatment, machine/engine, dispersed particle filtration, etc. It can solve the problems of downtime, high cost, and failure of the core material 92 to be used normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The technical means adopted by the present invention to achieve the intended creation purpose are further described below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

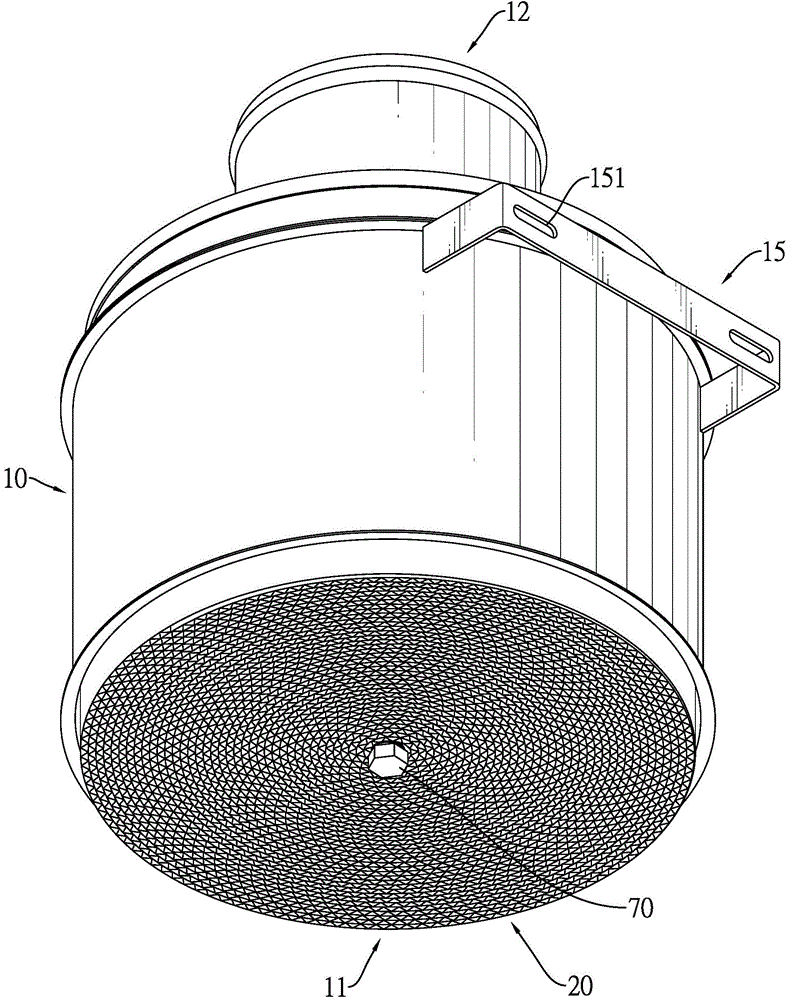

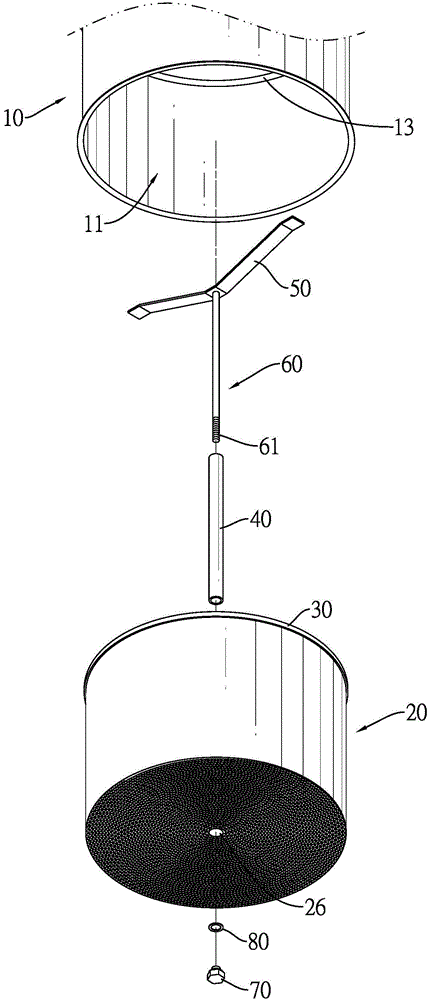

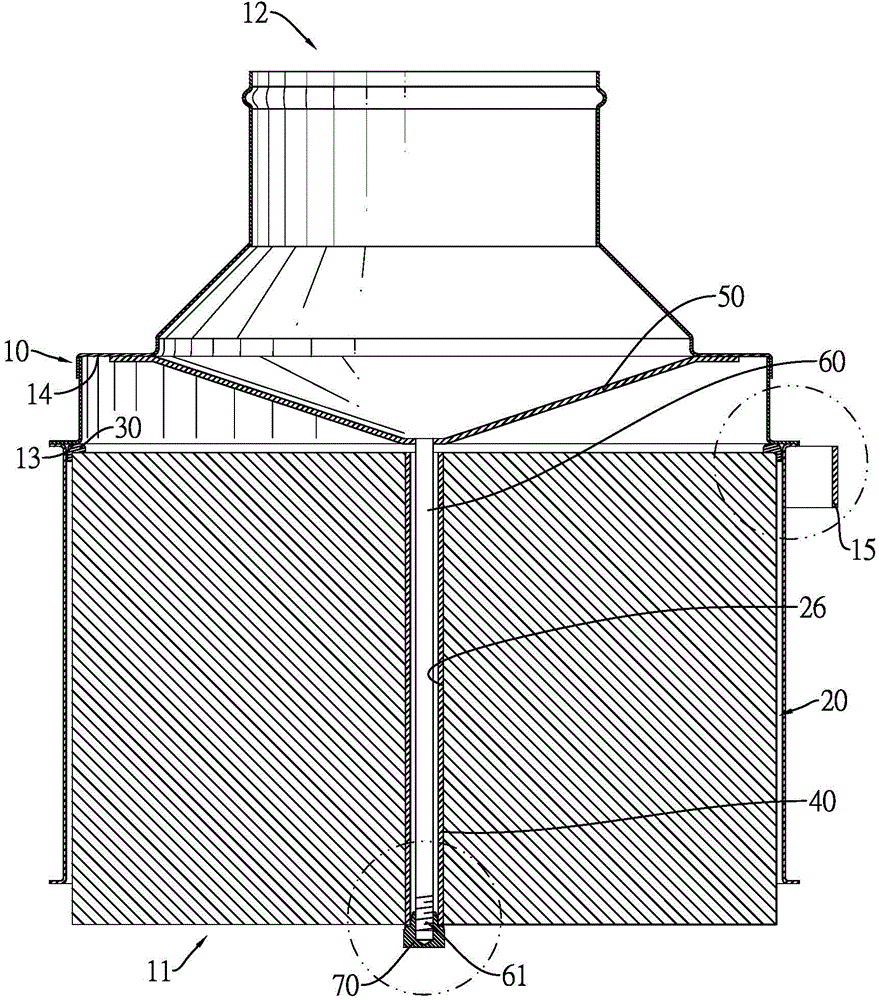

[0064] see figure 1 and figure 2 As shown, the air cleaner of the present invention includes a housing 10, a core material 20, an elastic abutment 30, a sleeve 40, a screw frame 50, a screw 60, a nut 70 and a gasket 80.

[0065] see Figure 1 to Figure 3 As shown, the aforementioned housing 10 has an accommodating space, an air inlet 11 and an air outlet 12, the air inlet 11 and the air outlet 12 are all communicated with the accommodating space; the inner wall of the housing 10 is surrounded by a first A first-stage surface 13 and a second-stage surface 14, the second-stage surface 14 is located between the first-stage surface 13 and the air outlet 12, and the inner diameter of the inner periphery of the second-stage surface 14 is smaller than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com