Lightweight steel structure building frame system

A technology of light steel structure and frame system, which is applied in the direction of building structure and construction, can solve the problems of unfavorable light waterproof concrete flow through, unfavorable standardized construction and quality control, low processing and installation efficiency, and reduce distance measurement Positioning process, improving construction efficiency, and reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

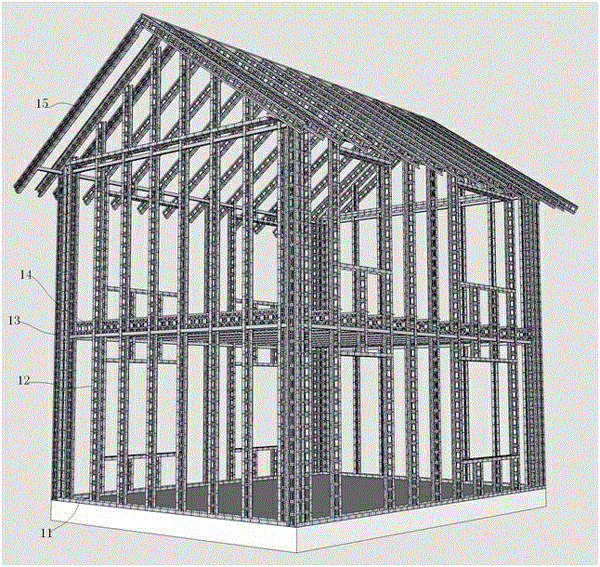

[0027] Such as figure 1 as shown, figure 1 A schematic diagram of the overall structure of an embodiment of a light steel structure residential frame system according to the present invention is shown. The embodiment of the present invention is used to quickly build a frame system of a light steel residential structure. Boards are installed inside and outside, and lightweight waterproof concrete is poured in the closed space formed by the boards and light steel components, that is, a light steel structure residence is built.

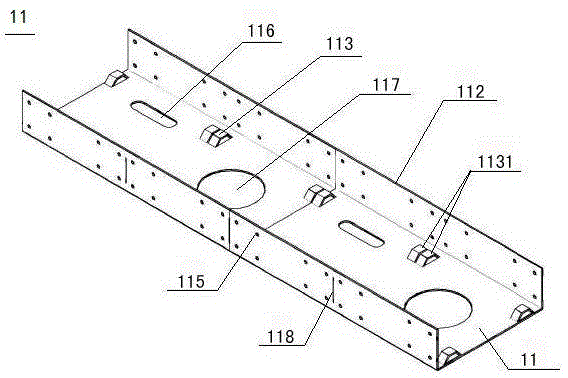

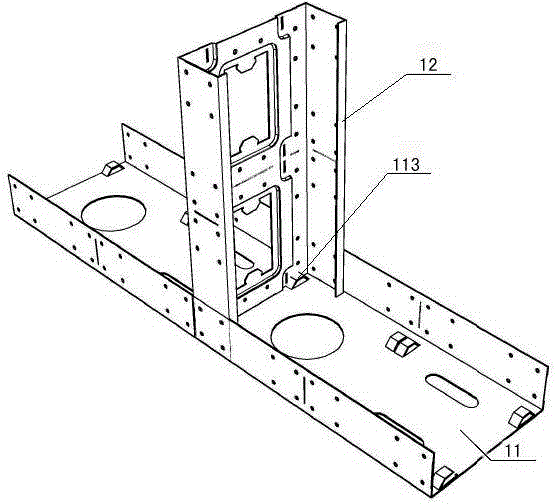

[0028] An embodiment of a light steel structure residential frame system in the present invention, comprising a steel ground beam 11, a steel beam column 12 vertically arranged on the steel ground beam 11, and a horizontally arranged ring beam fixedly connected to the steel beam column 12 13. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com