sweeper

A sweeping vehicle and main sweeping brush technology, which is applied in the field of sanitation and cleaning, can solve the problems of the limited cleaning range of the sweeping vehicle, cannot meet the needs of the sweeping vehicle, and occupy a large volume of the frame, and achieve a compact structure, convenient control, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

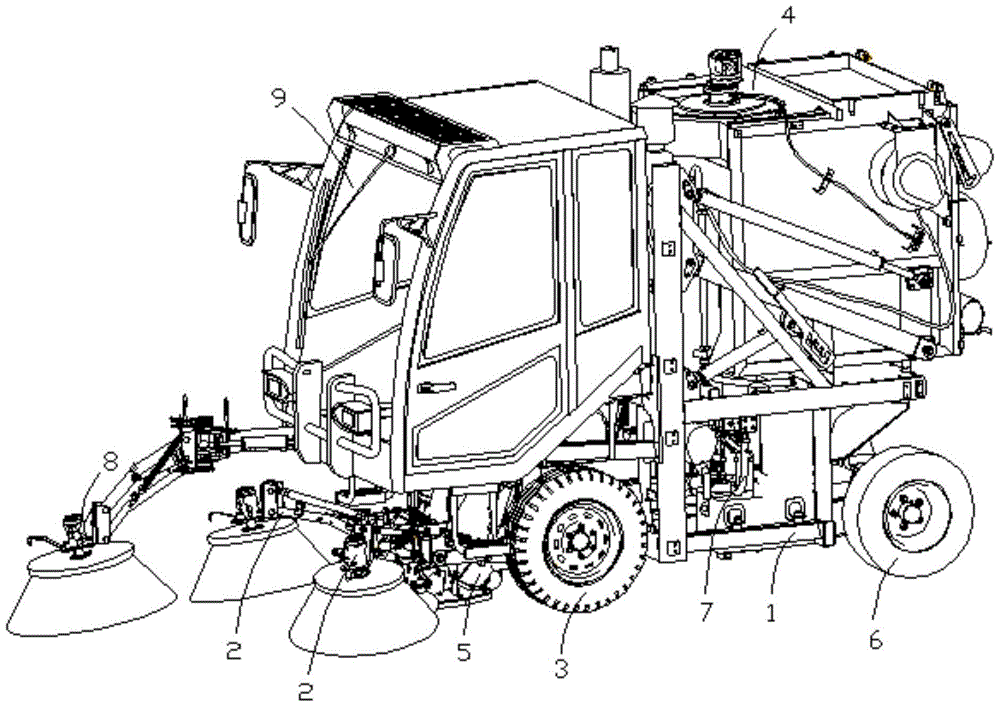

[0032] combine figure 1 As shown, the cleaning vehicle includes frame 1, cab 9, main sweeping brush device 2, front wheel assembly 3, material storage box 4, garbage collection device 5, oil tank, engine, diesel tank, rear wheel assembly 6 and spraying device 7.

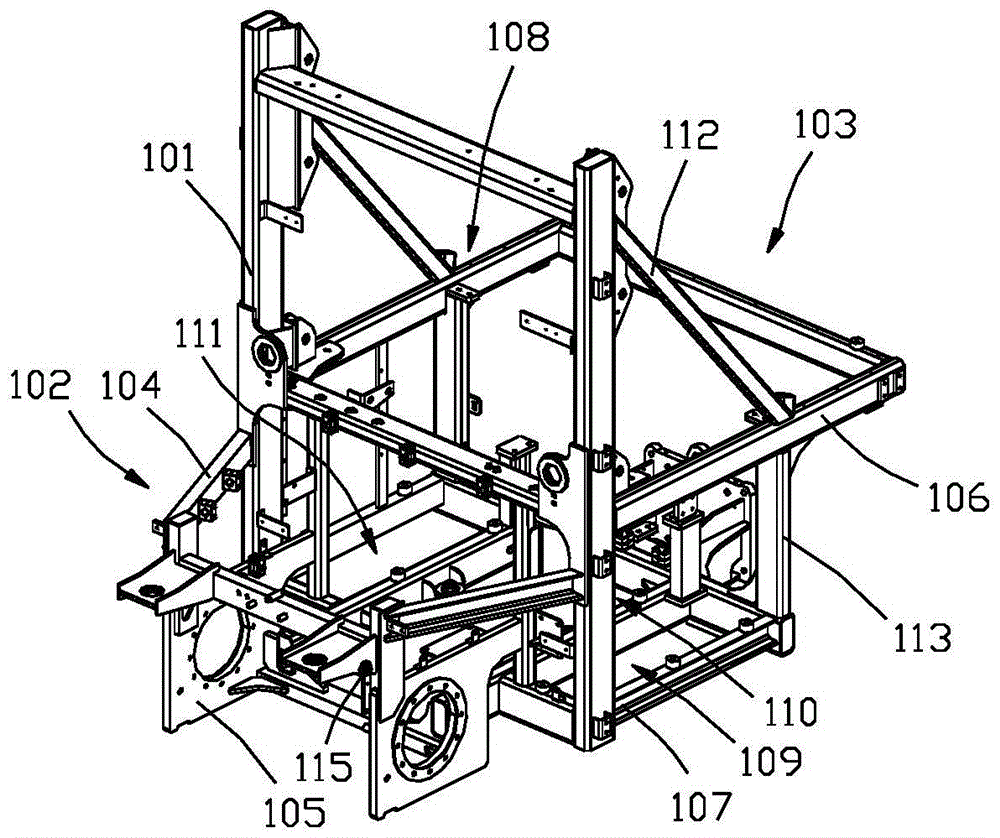

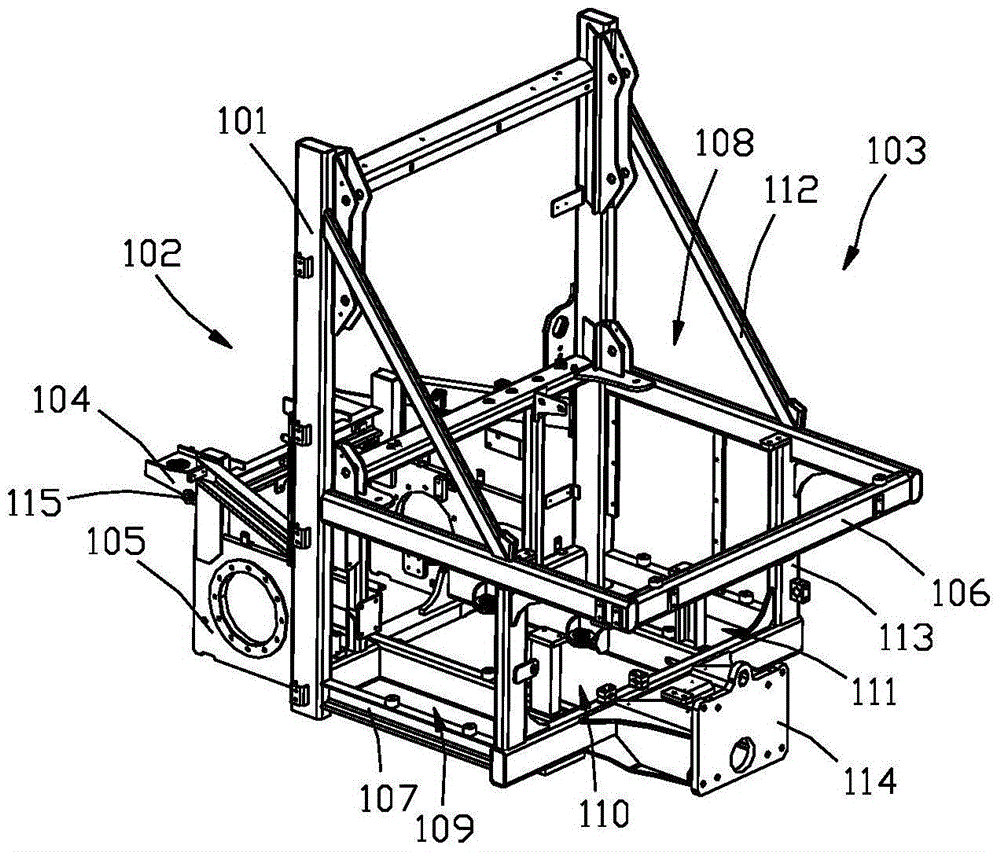

[0033] like figure 2 and image 3 As shown, the frame 1 includes a longitudinal support 101; with the longitudinal support 101 as a boundary, the frame is divided into two installation areas, front and rear, which are respectively a front installation area 102 and a rear installation area 103.

[0034] In the front mounting area 102, a cab mounting frame 104, a main sweeping device mounting frame 115 and a front wheel assembly mounting frame 105 are sequentially arranged from top to bottom. Wherein, the cab mounting frame 104 is used for mounting the cab 9 , the main sweeping devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com