Manufacturing method of target assembly

A production method and target technology, which are applied in the production field of target components, can solve the problems of lack of binding performance, inability to obtain binding rate and binding strength of target components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

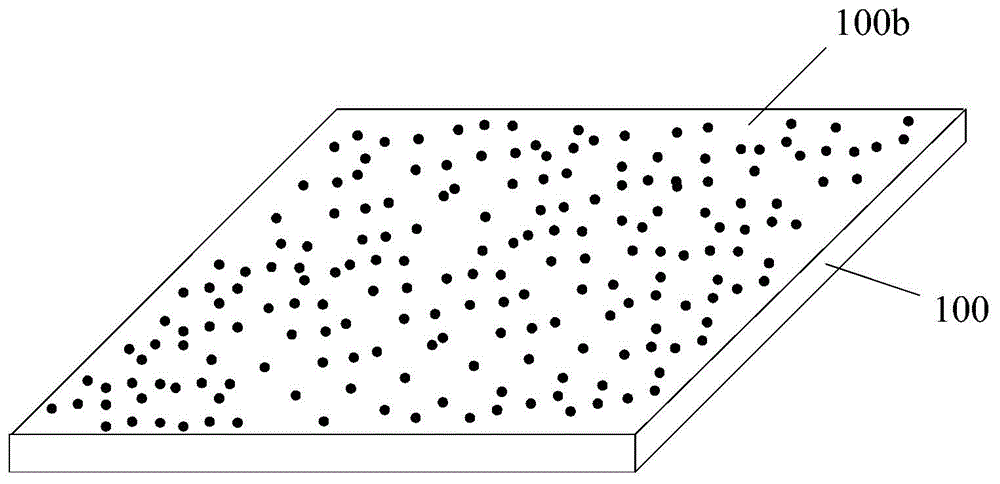

[0032] As mentioned in the background art, using the existing welding method, the direct welding of the molybdenum-silicon material and the back plate has a low bonding strength, which cannot meet the requirements of the semiconductor target, that is, the molybdenum-silicon material with the required bonding rate and bonding strength cannot be obtained. Target assembly.

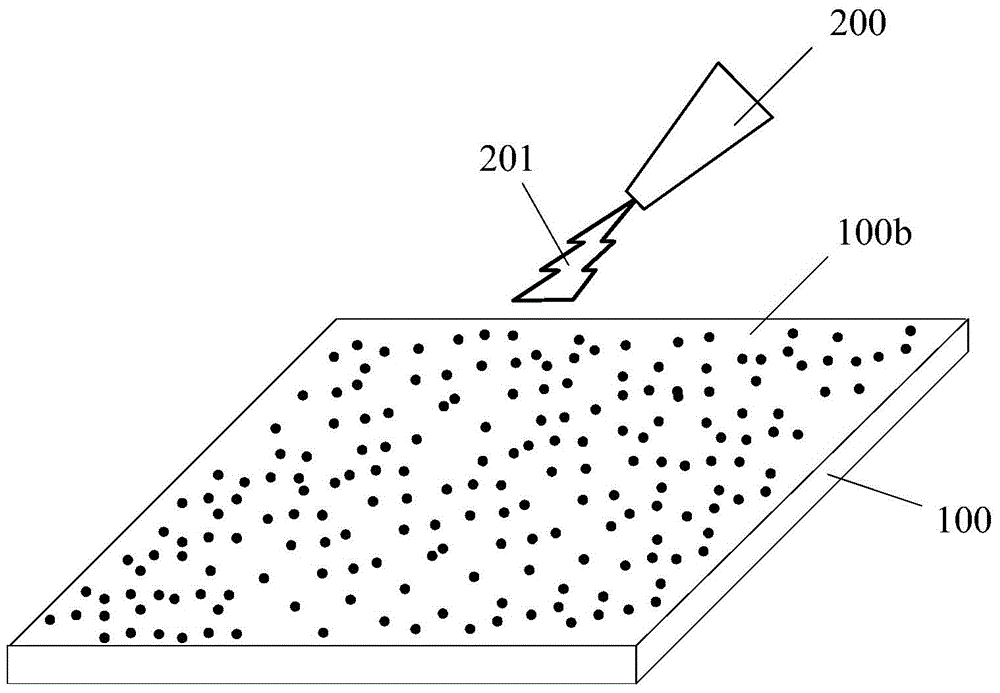

[0033] To this end, the present invention provides a new method for forming a target assembly. The method first provides a molybdenum-silicon material target, and then performs sandblasting on the to-be-welded surface of the target. Then, the target material is rinsed, and after the rinse treatment is performed on the target material, an activation treatment is performed on the to-be-welded surface of the target material, and after the activation treatment, an electroless plating process is used to A metal plating layer is formed on the to-be-welded surface of the target material, and the target material and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com