Asphalt concrete deceleration strip material as well as preparation method and construction technology thereof

An asphalt concrete and speed bump technology, applied in the directions of roads, road signs, traffic signals, etc., can solve the problems of weakened deceleration effect, large bearing gravity, and high cost of use of cast steel speed bumps, and achieves good integrity, reasonable shape, and increased Effects of stability and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation process of the asphalt concrete speed bump is as follows: add the above-mentioned weighed raw materials in the order of coarse aggregate → fine aggregate → mineral powder → anti-rutting agent → lignin fiber / polyester fiber → asphalt, and then follow the "Asphalt Pavement Construction Technical Specifications" for mixing to obtain the asphalt concrete speed bump.

[0016] The construction technology of the asphalt concrete speed bump is characterized in that it includes the following steps: 1) draw a line on the construction road section: use a line drawing tool to mark the place where construction needs to be done; 2) install the speed bump: first use a milling machine along the marked Mill the road surface to a set thickness, and use a grinder to smooth the milled road surface; remove residue and dust, and use emulsified asphalt to bond and install the prefabricated asphalt concrete speed bump; 3) Maintenance of speed bumps : Let it stand for 3-5 hours ...

Embodiment 1

[0018] An asphalt mixture-based energy-dissipating road stud and a preparation method thereof, which is composed of the following raw materials: 65kg of asphalt, 900kg of aggregate (including coarse aggregate and fine aggregate), 8kg of lignin fiber, 20kg of polyester fiber, Rutting agent 4kg, mineral powder 60kg. Among them, the asphalt is SBS modified asphalt, and Table 1 is the sieve distribution calculation table 1 of the aggregate.

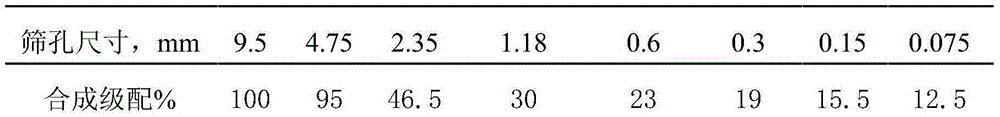

[0019] Table 1

[0020]

[0021] The preparation process of the asphalt mixture-based energy-dissipating road stud is as follows:

[0022] Add the above-mentioned raw materials in the order of coarse aggregate → fine aggregate → mineral powder → anti-rutting agent → lignin fiber / polyester fiber → asphalt, and then mix according to the "Technical Specifications for Asphalt Pavement Construction". Specifically: control the temperature at 180-200°C, stir the weighed aggregate and mineral powder in the pot, then add the anti-rutting agent an...

Embodiment 2

[0027] An asphalt mixture-based energy-dissipating road stud and a preparation method thereof, which is composed of the following raw materials: 68kg of asphalt, 924kg of aggregate (including coarse aggregate and fine aggregate), 7kg of lignin fiber, 18kg of polyester fiber, Rutting agent 3.5kg, mineral powder 60kg. Among them, the asphalt is SBR modified asphalt, and Table 2 is the sieve distribution calculation table of mineral materials.

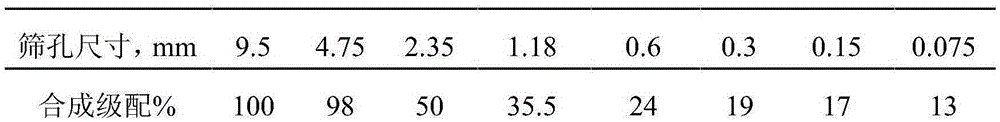

[0028] Table 2

[0029]

[0030] The preparation process of the asphalt mixture-based energy-dissipating road stud is as follows:

[0031] Add the above-mentioned raw materials in the order of coarse aggregate → fine aggregate → mineral powder → anti-rutting agent → lignin fiber / polyester fiber → asphalt, and then mix according to the "Technical Specifications for Asphalt Pavement Construction". Get said asphalt speed bumps.

[0032] The above-mentioned asphalt concrete material was then prepared as a Marshall test piece according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com