Full-automatic intermittent type pre-foaming machine

A pre-expanding machine and intermittent technology, which is applied in the field of foam machinery, can solve the problems of poor mixing effect, low degree of automation, and inability to dry beads, and achieve the effects of avoiding particle adhesion, good drying effect, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

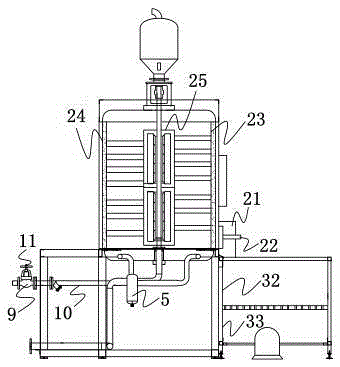

[0023] Such as figure 1 , 2 , 3, 4, and 5, a fully automatic intermittent pre-blowing machine, including a frame 1, a weighing device 2, a negative pressure feeding device 3, a pre-blowing machine cylinder 4, a steam delivery pipeline 5, a stirring Device 6, vulcanization and drying device 7 and control system 8, the steam delivery pipeline 5, pre-engine barrel 4 and control system 8 are installed on the frame 1, in order to avoid particles in the pre-engine barrel 4 after power failure Adhesion, on frame 1, also be installed with the power-off protection device 9 that links to each other for preventing the raw material in the pre-engine cylinder body 4 from sticking after power failure, further describe the power-off protection device 9, so The power-off protection device 9 includes a pipeline 10 connected to the pre-engine barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com