An automatic welding equipment for automobile radiator head

An automotive radiator, automatic welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high labor intensity, easy fatigue, radiator sealing effect and service life. , to achieve the effect of improving welding quality and welding efficiency and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

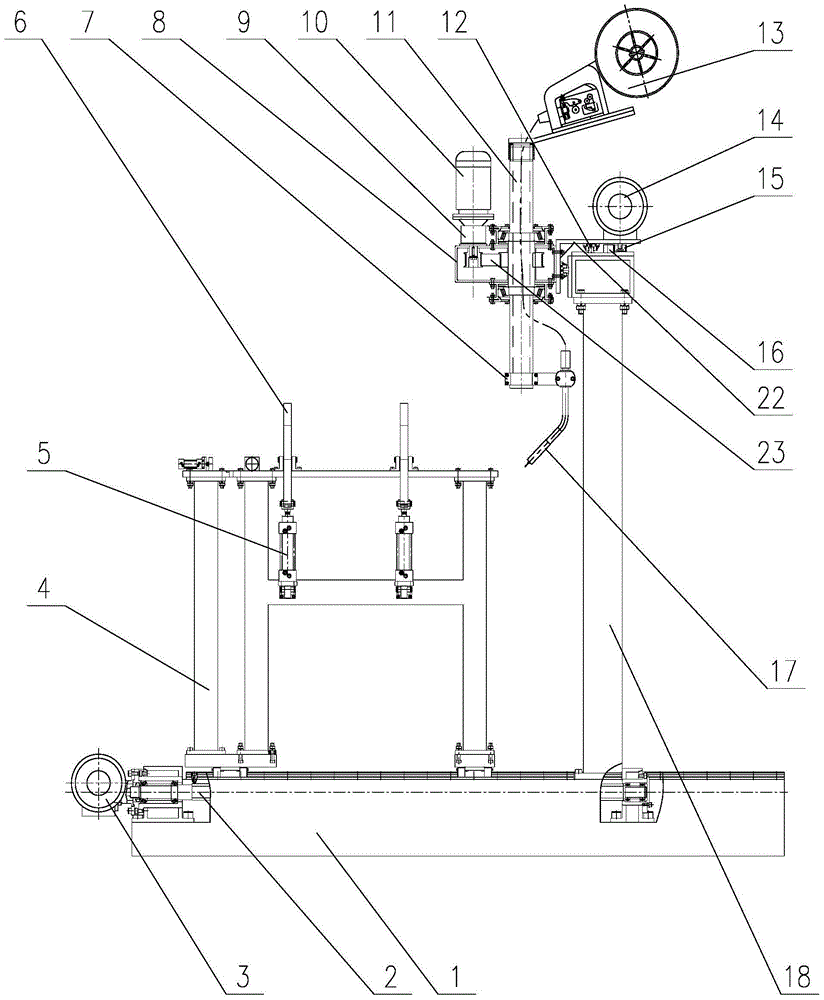

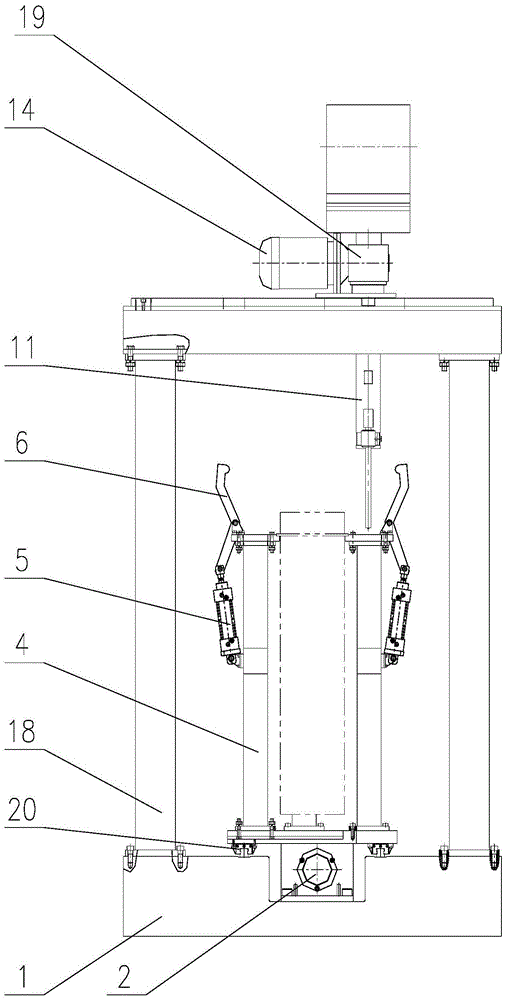

[0010] An automatic welding equipment for the head of an automobile radiator, which is composed of a base, a workbench, a pneumatic fixture, a gantry-type column and a welding mechanism, and is characterized in that: the base 1 has a transverse drive motor 3 and a transverse reducer 21 , ball screw 2 and horizontal linear guide rail 20 structure, the pneumatic clamp has a clamping cylinder 5, a hinge support, a pressure plate 6 and a pressure plate support structure, and the gantry type column has a rack 16, a longitudinal linear guide rail 12 structure, a horizontal drive motor 2 and a horizontal reducer 21 are installed on the base to drive the ball screw 2 to rotate, the worktable 4 is connected to the base through a horizontal linear guide rail 20, and the hinge support at the end of the clamping cylinder is installed on the worktable with bolts 4 side, the clamping cylinder 5 is installed on the hinge support, the cylinder rod is connected with one end of the pressure plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com