Double-acting forging tool for all-fiber crankshafts and forging method thereof

A full-fiber, crankshaft technology, applied in the field of forging, can solve the problems of increased manufacturing cost, low production efficiency, difficult adjustment, etc., and achieve the effects of improving production efficiency, simple structure, and easy speed adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

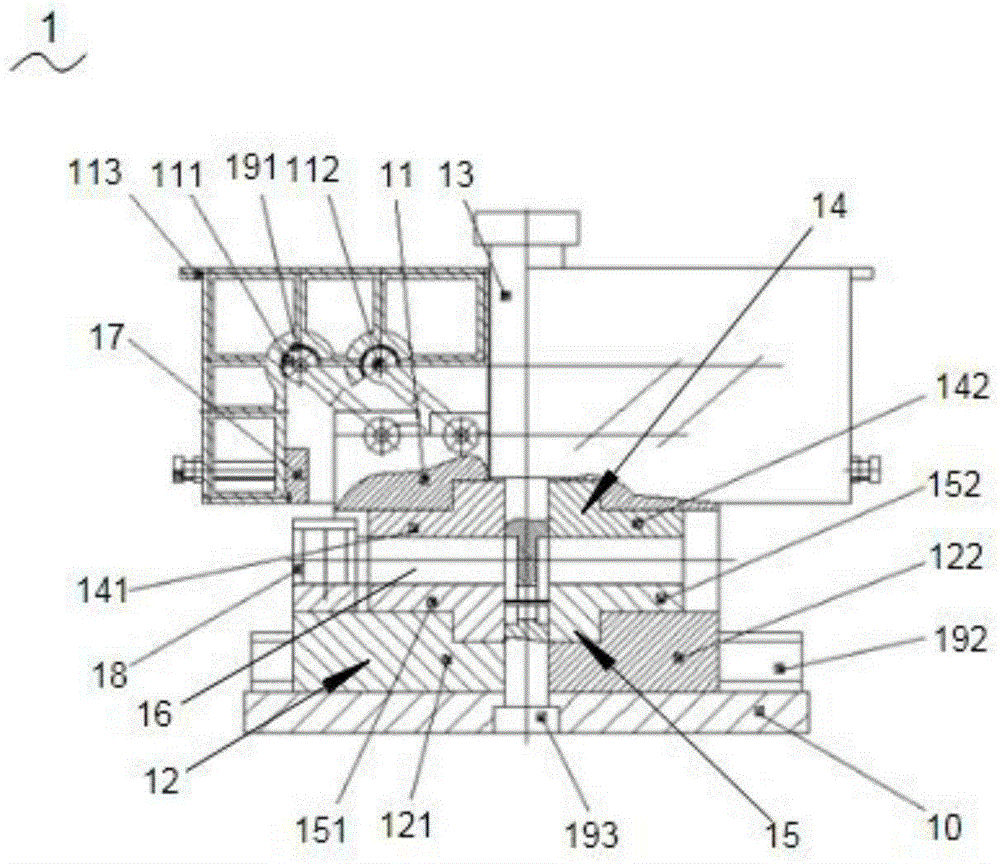

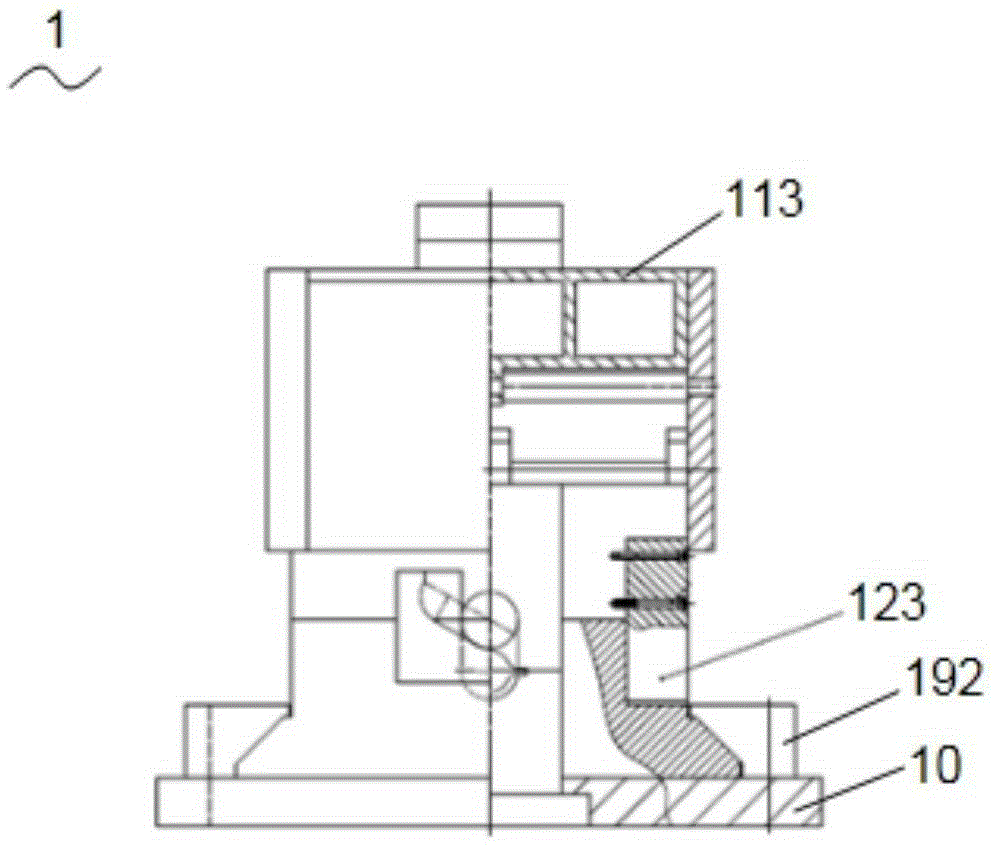

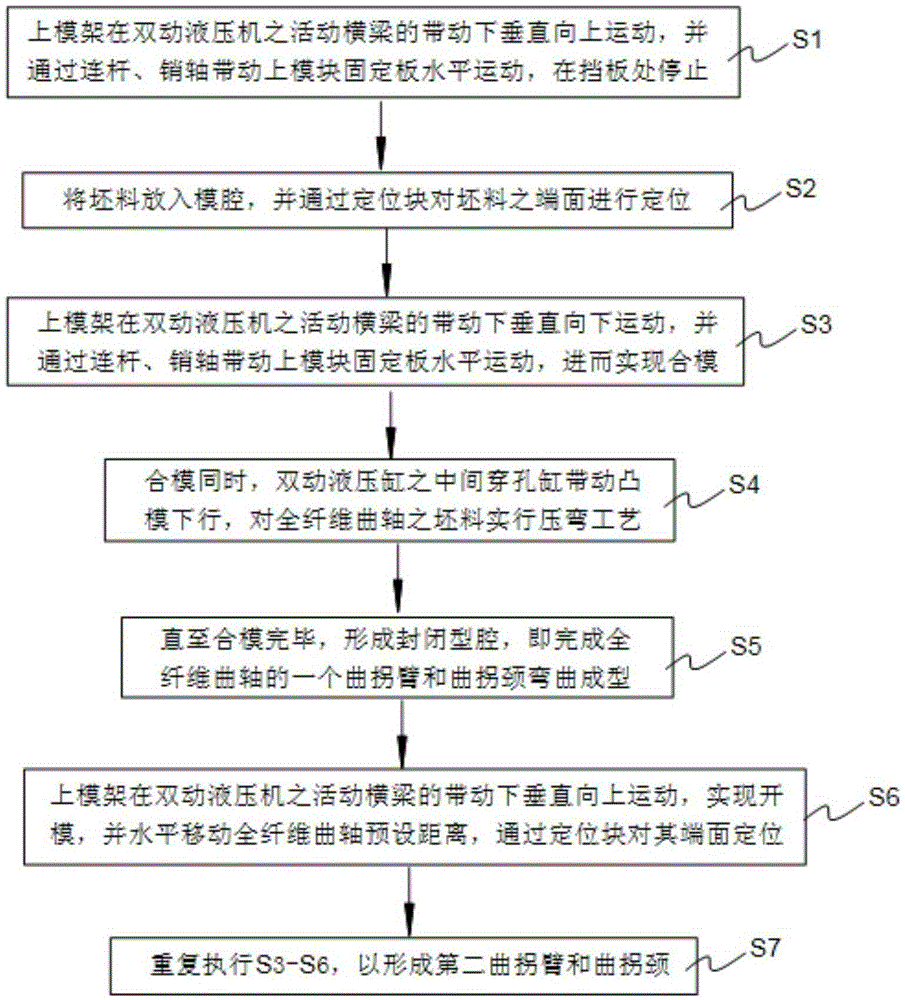

[0031] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0032] As we all know, the crankshaft is one of the important parts of the internal combustion engine, which is mainly used in locomotive traction devices and ship power devices. It is the main carrier of power conversion and output work. The multi-turn crankshaft is subjected to the combined action of periodically changing air pressure, inertial force caused by reciprocating and rotating motion, bending and torsional moment, and additional vibration stress during operation. Therefore, this requires the crankshaft to have high fatigue strength and structural strength. At present, there are mainly free forging and upsetting bending methods for forming full-fiber crankshafts. Both of these forging methods are completed on free forging hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com