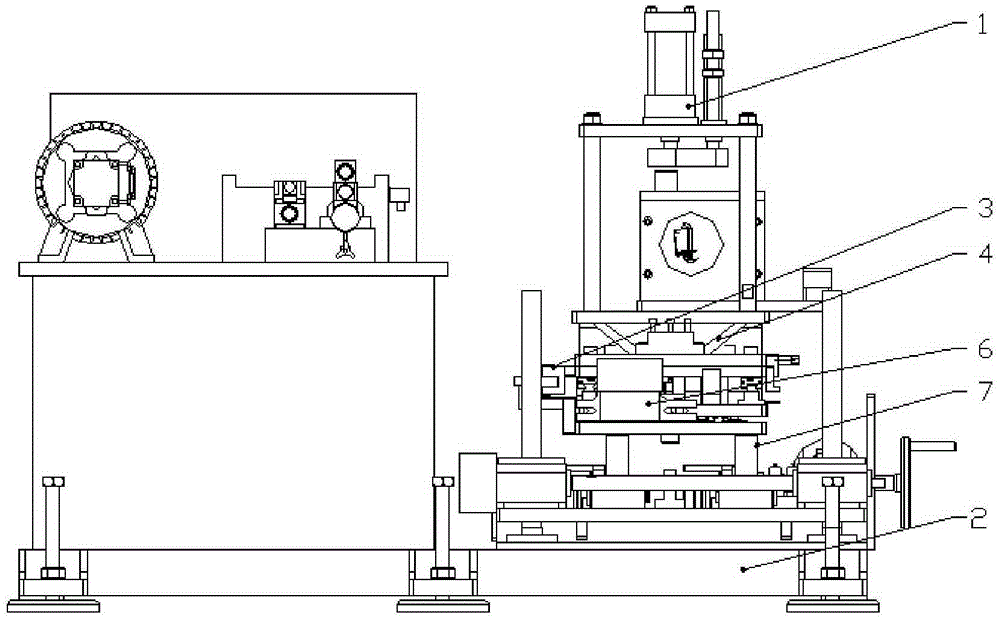

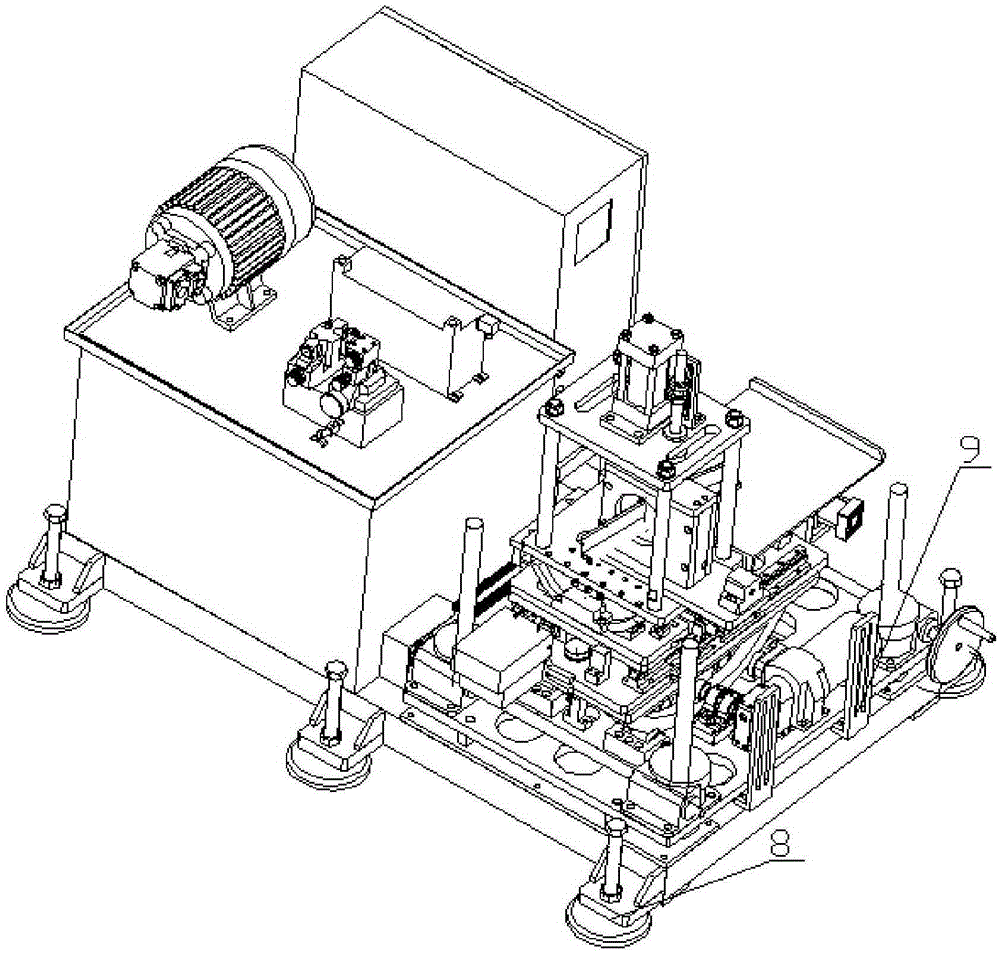

Fixed-length cutting-off equipment capable of adjusting cutting-off angle in multiple directions

A cutting equipment, multi-directional technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of high equipment cost, higher equipment function requirements, complicated operation, etc., to achieve low equipment cost, reduce production cost, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

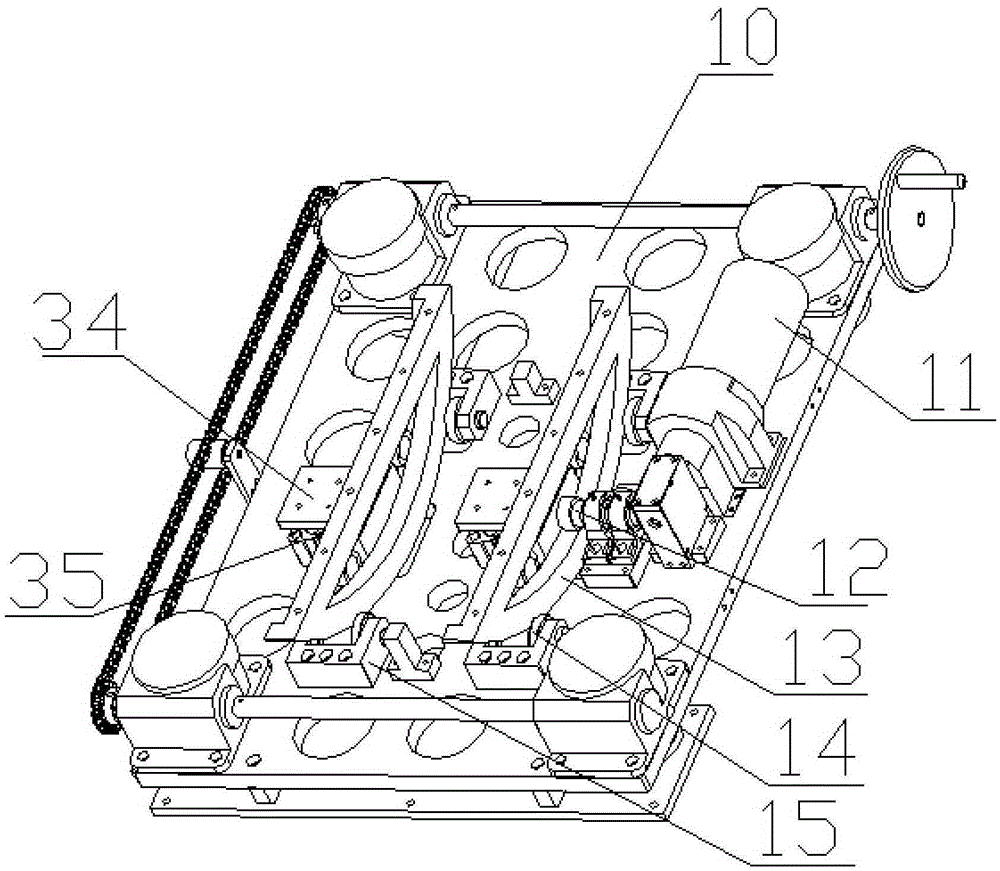

[0048] Install the equipment at the specified position, connect the power supply, water source, and air source, turn on the power switch, assemble the corresponding cutting die 30 on the punching mechanism 1, and then adjust the angles in different directions.

[0049] First, the front and rear radians are adjusted by the front and rear radian adjustment mechanism 7, the piston rod of the control cylinder 35 drives the pressing plate 34 to move upwards and separates from the semicircular connecting block 13, and the stepping motor 11 is started, and the output shaft of the stepping motor 11 drives the rotating shaft 12 to rotate. Rotating shaft 12 stretches into the arc groove provided in the middle of the half-arc connection block 13 and rotates, so that the arc surface at the lower end of the half-arc connection block 13 contacts and rolls with the roller 14 in the roller bracket 15, and the semi-arc connection block 13 The fixed plate 24 connected to the horizontal part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com