Efficient glass pipette processing and forming process and processing equipment

A technology for processing and molding and processing equipment, which is applied in the field of efficient processing and molding technology and processing equipment for glass pipettes, and can solve the problems of large floor space, restricting the production efficiency of glass pipettes, and complex equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

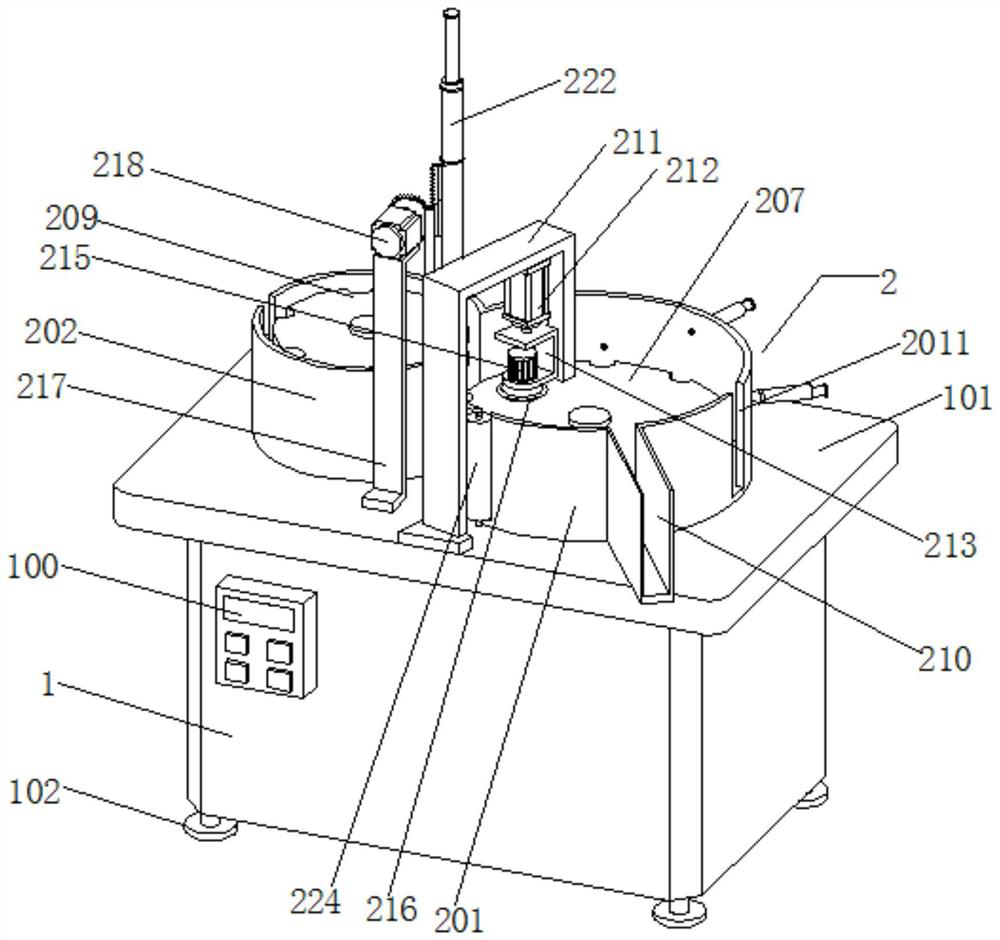

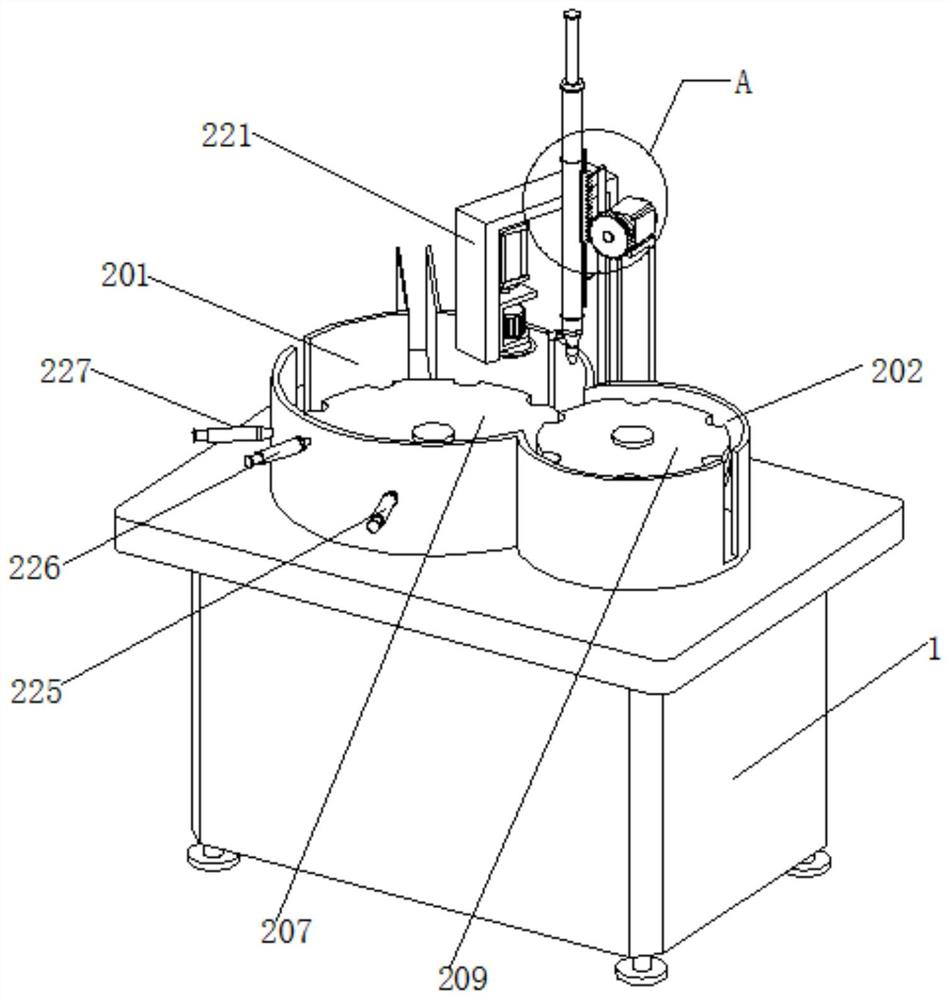

[0048] This embodiment 1 discloses a kind of processing equipment for preparing glass pipettes, referring to the attached figure 2 , attached image 3 , attached Figure 5 And attached Figure 6 , its main structure includes machine base 1 , pipe material vertical conveying device 2 and control panel 100 . A loading plate 101 is arranged on the upper surface of the machine base 1 , the pipe material vertical conveying device 2 is fixedly installed on the upper surface of the loading plate 101 , and the control panel 100 is arranged on the front side of the machine base 1 .

[0049] Reference attached Figure 4 , attached Figure 7 And attached Figure 8 , its pipe material vertical conveying device 2 comprises a first circular transfer cavity 201 and a second circular transfer cavity 202, wherein the first circular transfer cavity 201 and the second circular transfer cavity 202 are arranged tangentially, and the first The tangent points of the circular transmission cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com