A high-efficiency automatic cutting machine

A cutting machine, automatic technology, applied in metal processing and other directions, can solve the problems of reducing processing efficiency and yield, unable to quickly realize positioning cutting, low accuracy of sheet fixed-length cutting, etc., to improve processing efficiency and Yield, convenient continuous cutting, light structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

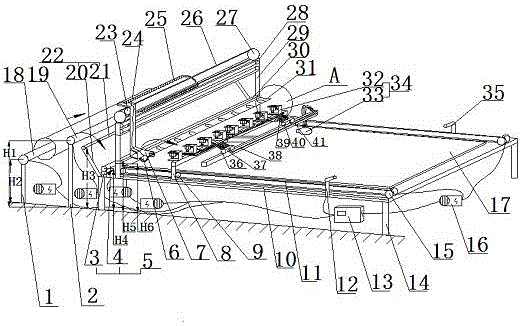

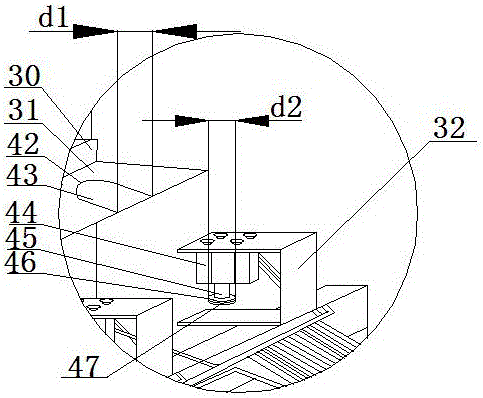

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] A high-efficiency automatic cutting machine, comprising a material roller 1, a material rack 2, a machine tool 14, a motor 16 and an electrical controller 13, wherein the material roller 1, the material rack 2 and the machine tool 14 are arranged in parallel on a straight line, and the The material roller 1 has a first roller shaft 18, and the distance from the first roller shaft 18 to the ground is H1, and the material rack 2 has a second roller shaft 19, and the distance from the second roller shaft 19 to the ground is H2, so H2>H1, the lathe 14 is provided with a bed board 17, and the head of the lathe 14 is provided with a lifting frame 22, a folding frame 5, a protruding rod 30 and a clamping platform 31 from the outside to the inside. The lifting frame 22 includes a horizontal bar 21 and two inclined bars 20, the inclined bars 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com