Boiling water enzyme deactivating method of fresh tea leaf

A technology for fresh tea leaves and greening, applied in the direction of tea treatment before extraction, can solve the problems of difficult cleaning of the drum, low product quality, affecting product quality, etc., and achieve the effects of improving product quality, ensuring extraction rate, and ensuring product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

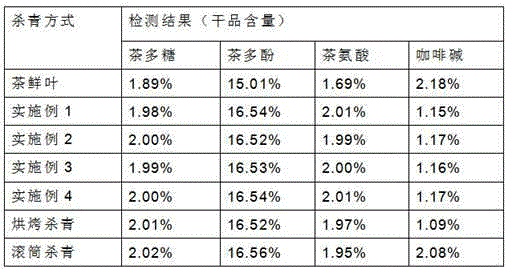

Examples

Embodiment 1

[0029] A method for boiling fresh tea leaves to quench the greens, including the following steps:

[0030] Step (1), picking and conveying of fresh tea leaves: After picking the fresh tea leaves, take 87.8 kg of fresh tea leaves and send them to the steaming and blanching machine using a material conveyor;

[0031] Step (2), boiling water for curing: add water to the steaming and blanching machine according to the mass ratio of fresh tea leaves to water for curing at a mass ratio of 1:1, and curing at 90°C for 120s, at a speed of 1.2r / min;

[0032] Step (3), spray cooling: the tea leaves obtained by boiling water quenching in step (2) are atomized and sprayed to room temperature with a spray cooler to complete the curing;

[0033] The atomized spray cooling method is spraying once every 2 minutes, every 10 seconds, and the spray water temperature is 8°C;

[0034] The spray pressure of the atomized spray cooling is 0.15MPa, and the flow rate is 8L / h.

Embodiment 2

[0036] A method for boiling fresh tea leaves to quench the greens, including the following steps:

[0037] Step (1), picking and conveying of fresh tea leaves: After picking the fresh tea leaves, take 100kg of fresh tea leaves and send them to the steaming and blanching machine using a material conveyor;

[0038] Step (2), boiling water for curing: add water to the steaming and blanching machine according to the mass ratio of fresh tea leaves to water for curing at a mass ratio of 1:1, and curing at 95°C for 120s, at a speed of 1.5r / min;

[0039] Step (3), spray cooling: the tea leaves obtained by boiling water quenching in step (2) are atomized and sprayed to room temperature with a spray cooler to complete the curing;

[0040] The atomized spray cooling method is spraying once every 3 minutes, 20s each time, and the spray water temperature is 10°C;

[0041] The spray pressure of the atomized spray cooling is 0.2 MPa, and the flow rate is 10 L / h.

Embodiment 3

[0043] A method for boiling fresh tea leaves to quench the greens, including the following steps:

[0044] Step (1), picking and conveying of fresh tea leaves: After picking the fresh tea leaves, take 92.5 kg of fresh tea leaves and send them to the steaming and blanching machine using a material conveyor;

[0045] Step (2), boiling water for curing: add water to the steaming and blanching machine according to the mass ratio of fresh tea leaves to water for curing at 1:0.9, and curing at 96°C for 115s, and the speed of curing is 1.0r / min;

[0046] Step (3), spray cooling: the tea leaves obtained by boiling water quenching in step (2) are atomized and sprayed to room temperature with a spray cooler to complete the curing;

[0047] The atomized spray cooling method is spraying once every 2.5min, 15s each time, and the spraying water temperature is 9°C;

[0048] The spray pressure of the atomized spray cooling is 0.17 MPa, and the flow rate is 9 L / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com