Threshing device of harvester

A technology of threshing device and harvester, which is applied to harvesters, threshing equipment, cutters, etc., can solve the problems of increasing equipment cost, less time, and no consideration, and achieve the effects of improving threshing efficiency, increasing contact rate, and reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

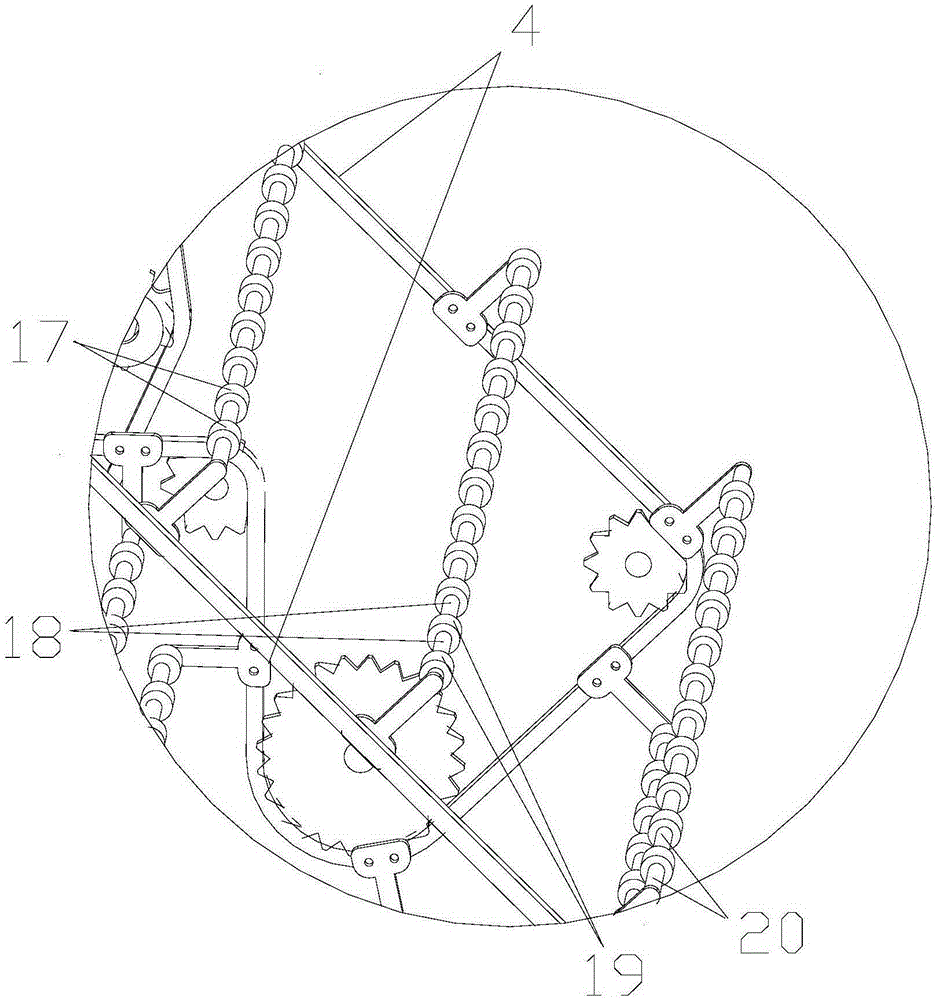

[0022] refer to figure 1 , figure 2 , the present embodiment includes a threshing cylinder 1, the surface of the threshing cylinder 1 is provided with a plurality of threshing teeth 2, and also includes a grain guide 3, and the grain guide 3 includes a grain guide chain 4, a plurality of grain guide sprockets, and a plurality of root presses. Grain cross bar 6 and grain pressing cross bar 6 are fixed overhead on the grain guiding chain 4 and move back and forth with the grain guiding chain 4. The grain guiding chain 4 is located above or on the side of the threshing drum 1, and it is in the same position as the section near the threshing drum 1. Approximate " W " shape, i.e. double " V " shape, there are two nearest tangent points between the pressing grain horizontal bar 6 and the threshing cylinder 1 that are contained on it. There are two grass-guiding chains 4, two groups of grass-guiding sprockets, two groups of grass-guiding sprockets and two grass-guiding chains move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com