Electric-hydraulic hybrid anti-rupture anti-compression synchronous test machine

A testing machine, hydraulic technology, applied in the flexural and compressive material testing equipment, patented electric-hydraulic hybrid flexural and compressive synchronous testing machine field, can solve the problem of poor control of the flexural part, fatigue of the operator, and oil leakage and other issues, to achieve the effect of improving work efficiency and machine utilization, shortening the test waiting time, and reducing the structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the patent of the present invention is further described.

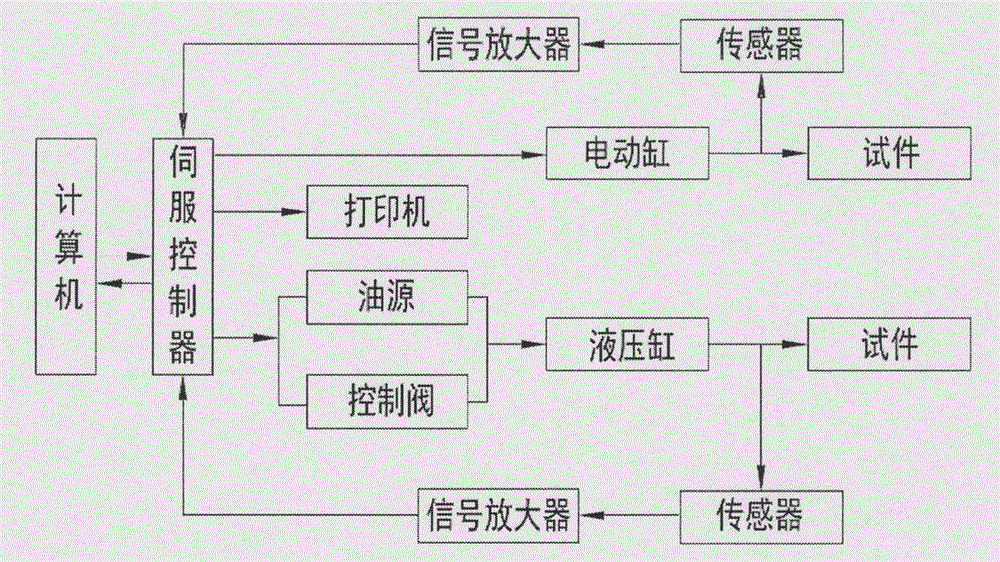

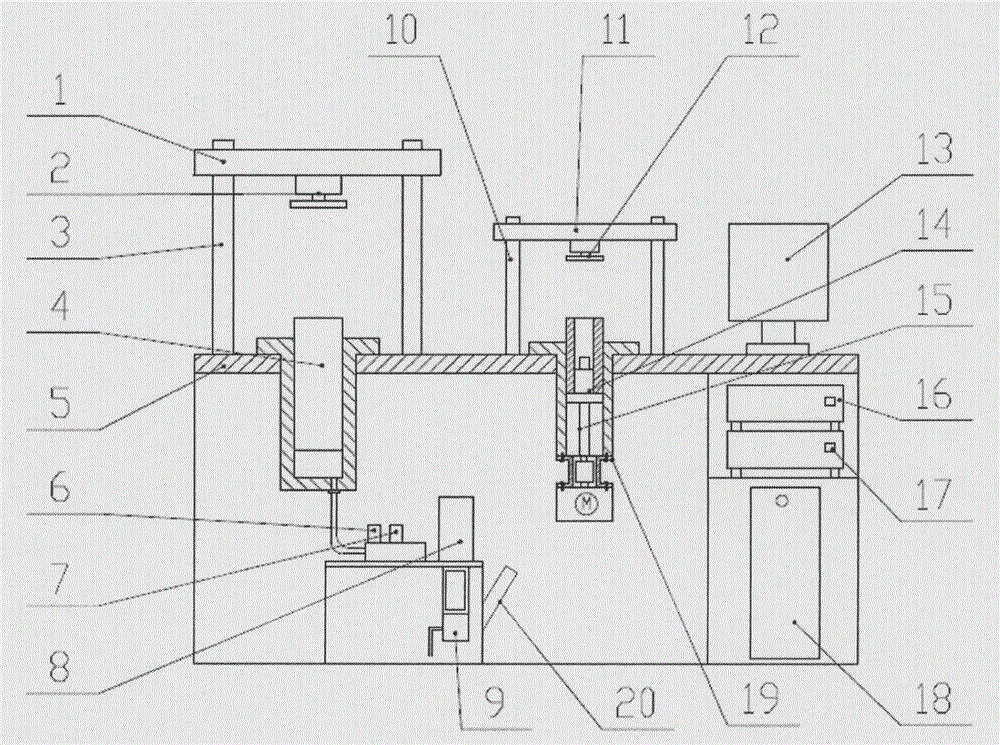

[0014] Such as Figure 1-2 As shown, an electric-hydraulic hybrid anti-bending and anti-compression synchronous testing machine, the main structural parts of this machine include an electric cylinder (19) with a screw rod, a compression cylinder (4), an anti-bending column (10), and a bending-resistant beam (12), anti-compression column (3), anti-compression beam (1), pressure reducing valve (7), digital valve (6), oil tank (20), oil pump (9), double-acting pressure-bearing test bench (5) , computer data control program, servo controller (16), computer host (18), computer monitor (13), printer (17), pressure sensor (2), motor (8), bending sensor (12), wire Rod nut (14), screw mandrel (15) form.

[0015] When the testing machine works, start the computer (18), and open the testing software program in the computer monitor (13) by operating the mouse and the keyboa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com