Plastic composite drainage pipe provided with electric heating fuses for thermal connection

A technology of electric heating fuse and drainage pipe, which is applied in the direction of pipe connection arrangement, pipe/pipe joint/pipe fitting, pipe, etc., can solve the problems of poor sealing effect, insufficient ring stiffness at the connection, inconvenience, etc., and achieves fast installation. Safety, good connection effect, scientific design effect

Inactive Publication Date: 2016-01-27

湖北铭航新能源科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In various drainage projects such as urban rain and sewage discharge, road engineering, and construction engineering, deep-seated composite drainage pipes are generally used as drainage pipes. This traditional composite drainage pipe can be bent as it is used, and it is extremely convenient to use. During the installation process, there are certain troubles in the interconnection between the pipe bodies. The current composite drainage pipes generally adopt flange connection, hot-melt belt connection, electric fusion belt connection or butt welding and add gaskets between each other in design. Closed connection, but these common designs are very inconvenient in actual installation, and the connection cannot reach the corresponding ring stiffness, which directly leads to poor sealing effect, and the phenomenon that plant roots will damage the pipe at the leakage position, especially Butt welding is also limited by the caliber of the operation, thicker pipes cannot be connected by butt welding at all

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

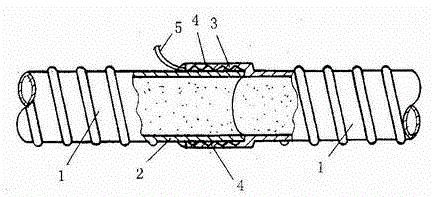

[0008] figure 1 As shown: the composite drainage pipe used for drainage is provided with an electric fuse 4 surrounding the joint at the intersection of the plug 2 and the socket 3 where the two pipe bodies 1 are connected.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a plastic composite drainage pipe provided with electric heating fuses for thermal connection. The plastic composite drainage pipe comprises pipe bodies (1) and is characterized in that the electric heating fuses (4) surrounding a connector are arranged at the intersection of an insertion head (2) and an insertion opening (3) for connection of the two pipe bodies (1) of the composite drainage pipe used for draining, and the electrified fuse heads (5) of the electric heating fuses (4) are located on the outer side of the insertion opening (3).

Description

technical field [0001] The invention relates to a plastic composite drainage pipe, in particular to a plastic composite drainage pipe provided with an electric heating fuse heat-sealing connection. Background technique [0002] In various drainage projects such as urban rain and sewage discharge, road engineering, and construction engineering, deep-seated composite drainage pipes are generally used as drainage pipes. This traditional composite drainage pipe can be bent as it is used, and it is extremely convenient to use. During the installation process, there are certain troubles in the interconnection between the pipe bodies. The current composite drainage pipes generally adopt flange connection, hot-melt belt connection, electric fusion belt connection or butt welding and add gaskets between each other in design. Closed connection, but these common designs are very inconvenient in actual installation, and the connection cannot reach the corresponding ring stiffness, which...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16L9/12F16L47/03

Inventor 王立峰李欣王宪华

Owner 湖北铭航新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com