Zero-clearance arc swing mechanism based on machine tool and implementation method thereof

A swing mechanism, no gap technology, applied in mechanical equipment, transmission, belt/chain/gear, etc., can solve the problems of insufficient driving rigidity, increased backlash, gap, etc., and achieve the effect of overcoming defects and eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

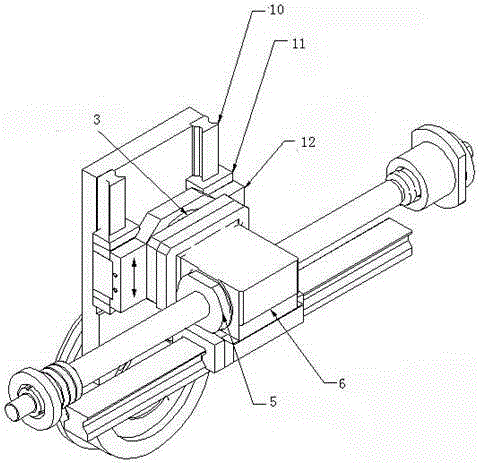

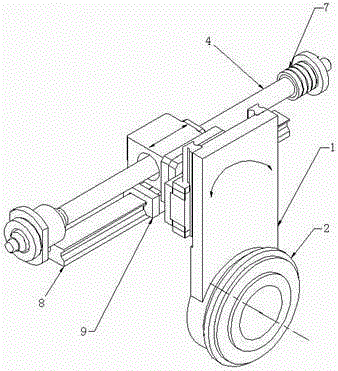

[0023] like figure 1 , 2 As shown, this embodiment provides a gapless arc swing mechanism based on a machine tool. The swing mechanism includes two transmission pairs: a rolling linear guide pair and a ball screw transmission pair. The two transmission pairs are connected by a second direction Central thrust combination bearing connection, through the cooperation of two transmission pairs, the linear motion generated by the ball screw is transformed into the arc swing motion of the terminal driven swing element, which completely eliminates the gap in the entire transmission chain and improves the transmission accuracy And rigidity and long-lasting precision retention.

[0024] The oscillating plate driven to perform reciprocating oscillating motion is connected with the fixed frame through the first thrust centripetal combined bearing, and the specific method is as follows: the inner ring of the first centripetal thrust combined bearing is fixedly connected with the oscillati...

Embodiment 2

[0030] In this embodiment, there is no swing guide plate, and there is only one second slider, and the two sides of the second slider are respectively installed on two guide rails, and its end faces are directly connected with the second centripetal thrust combined bearing, and the rest of the structure and implementation Example 1 is the same.

Embodiment 3

[0032] In this embodiment, another horizontal linear drive mechanism is used to replace the ball screw drive pair, which may include a guide rail fixed on the frame, and a slider installed on the guide rail. The slider also passes the second centripetal thrust The combined bearing is connected with the second slider or the swing guide plate, and the movement of the slider relative to the guide rail can be driven by a built-in motor. Its working principle is the same as that of Embodiment 1, so it will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com