Self-rotation-free traction type stepless speed changer

A continuously variable transmission, traction type technology, applied in the direction of vehicle gearbox, friction transmission device, transmission element, etc., can solve the problems of troublesome speed control, difficult manufacturing, wear of belt and pulley, etc. The effect of convenient speed control and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

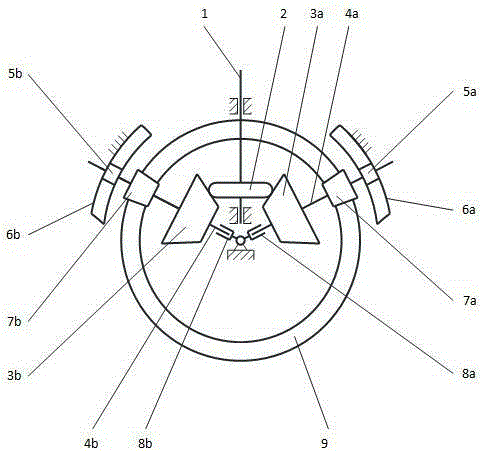

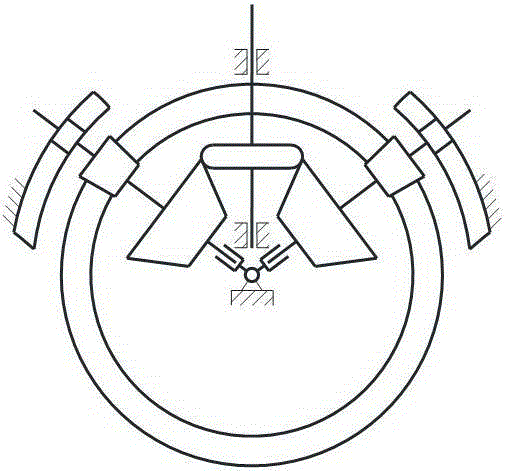

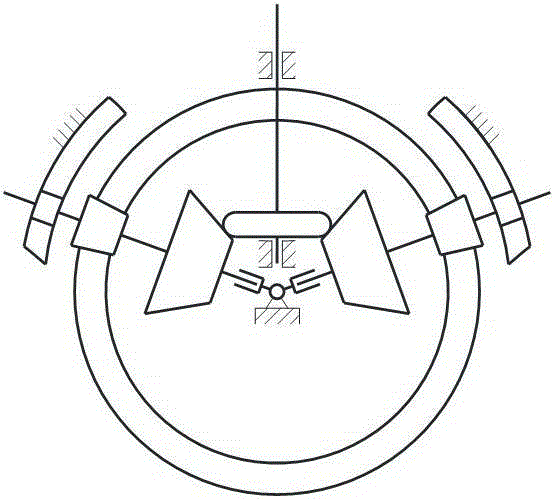

[0014] Combine now figure 1 , to describe in detail the specific embodiments of the present invention.

[0015] The non-spin traction continuously variable transmission mainly consists of an input shaft (1), a driving roller (2), a first driven cone (3a), a second driven cone (3b), and a first intermediate shaft (4a) , the second intermediate shaft (4b), the first slider (5a), the second slider (5b), the first guide rail (6a), the second guide rail (6b), the first bevel pinion (7a), the second Small bevel gear (7b), the first swing support (8a), the second swing support (8b) and large bevel gear (9).

[0016] The driving roller (2) is installed on the input shaft (1), and it can move along the axis of the input shaft (1), but cannot rotate relative to the input shaft (1). The driving roller (2) is in the shape of a disk, and its generatrix is in the shape of an arc, and has a simple structure and is easy to manufacture.

[0017] The first driven cone (3a) and the first sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com