Waste water zero-discharge acetylene production technology

A production process and zero-emission technology, applied in acetylene generators, parts of acetylene gas generators, petroleum industry, etc., can solve problems such as incomplete reaction between calcium carbide and water, and achieve favorable management and control, and stable process parameters , The effect of reasonable and safe process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

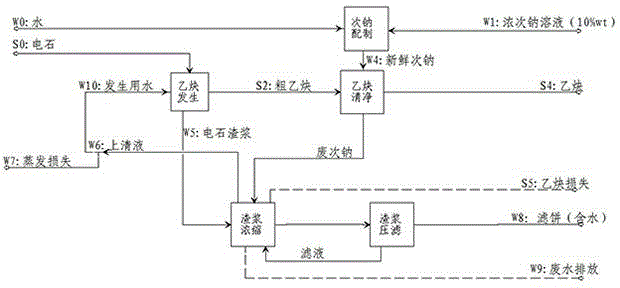

Image

Examples

Embodiment 1

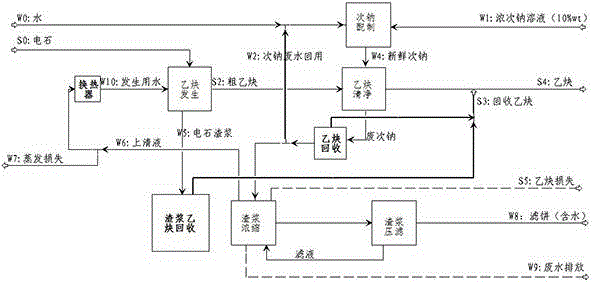

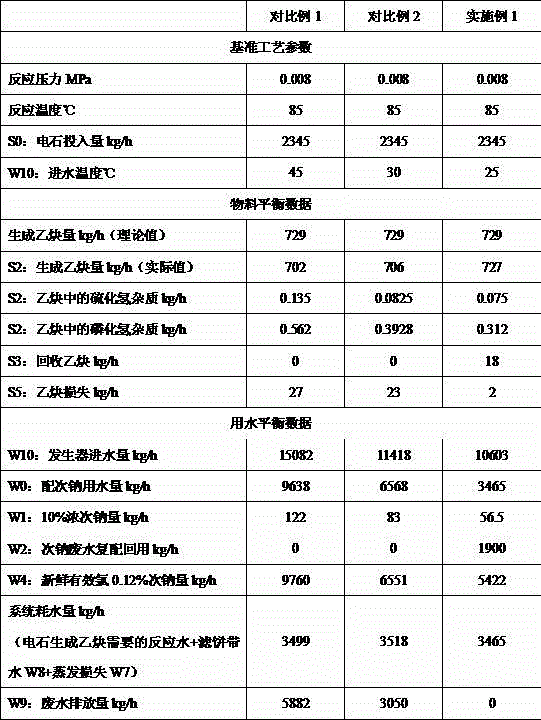

[0027] Such as figure 2 As shown, after the water from the clear liquid pool passes through the heat exchanger to regulate the temperature, it is fed into the acetylene generator at the same time as calcium carbide at a predetermined flow rate, and the pressure and temperature of the generator are kept at the set values. The calcium carbide and water in the generator generate reaction to generate acetylene gas and calcium carbide slurry; the acetylene gas is washed and compressed from the top of the generator in sequence, and then enters the acetylene cleaning station, and is removed with a fresh sodium solution with an available chlorine of 0.1% to 0.12% and a pH value of 7 to 8 In addition to impurities such as hydrogen sulfide and phosphine in acetylene gas, the sub-sodium wastewater enters the first desorption tower and is sprayed under negative pressure conditions. After removing acetylene gas, part of the sub-sodium wastewater goes to the sub-sodium compounding device, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com