Gravure pearlescent printing ink with excellent storage property and preparation method therefor

A pearlescent ink and storage technology, which is applied in the field of gravure printing pearlescent ink and its preparation, can solve the problems of pearlescent ink being placed for a long time and is easy to be scrapped, and achieve the effects of reducing the problem of agglomeration and scrapping, low production cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

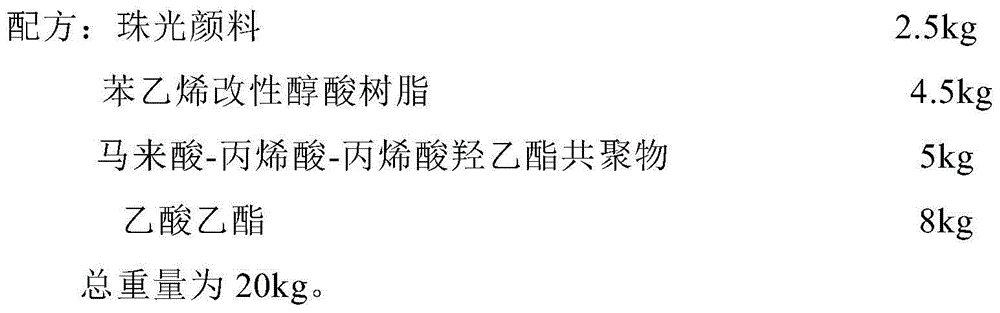

Embodiment 1

[0035]

[0036] Preparation:

[0037] 1.1 Weighing ingredients: Weigh each raw material according to the above formula into different stainless steel barrels for later use;

[0038] 1.2 Dispersion: Put 8kg of ethyl acetate in a mixing tank, slowly add 2.5kg of pearlescent pigment into the ethyl acetate under stirring until the pearlescent pigment is completely dissolved, continue stirring, and mix 9.5kg of benzene Ethylene-modified alkyd resin and maleic acid-acrylic acid-hydroxyethyl acrylate copolymer mixed binders are gradually added to the above pearlescent solution, stirred and dispersed evenly;

[0039] 1.3 Potting and packaging: Accurately weigh a certain amount of pearlescent ink according to the weight of the package, put it into the ink barrel, cover and seal the barrel, and stick a label to obtain the finished pearlescent ink.

[0040] After the production of the above ink is completed and placed for 3 months, there is no hard sediment at the bottom, and it can ...

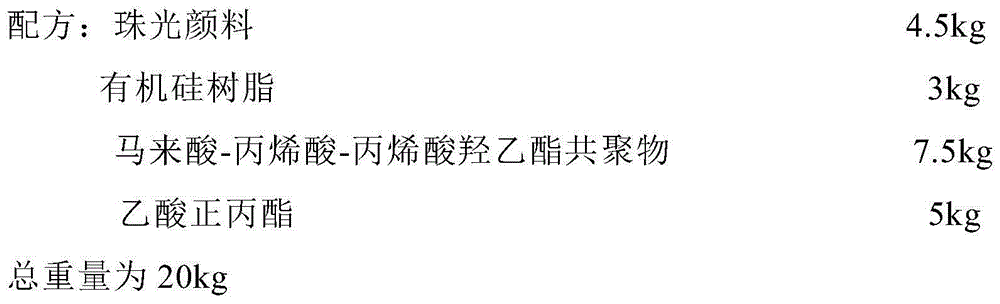

Embodiment 2

[0042]

[0043] Preparation:

[0044] 2.1 Weighing ingredients: Weigh each raw material according to the above formula into different stainless steel barrels, and set aside;

[0045] 2.2 Dispersion: Put 5kg of n-propyl acetate in a mixing tank, slowly add 4.5kg of pearlescent pigment into n-propyl acetate under stirring until the pearlescent pigment is completely dissolved, continue stirring, and mix 10.5kg of The silicone resin and the maleic acid-acrylic acid-hydroxyethyl acrylate copolymer mixed binder are gradually added to the above-mentioned pearlescent solution, stirred and dispersed evenly;

[0046] 2.3 Potting and packaging: Accurately weigh a certain amount of pearlescent ink according to the weight of the package, put it into the ink barrel, cover and seal the barrel, and stick a label to obtain the finished pearlescent ink.

[0047] After the production of the above ink is completed and placed for 3 months, there is no hard sediment at the bottom, and it can be...

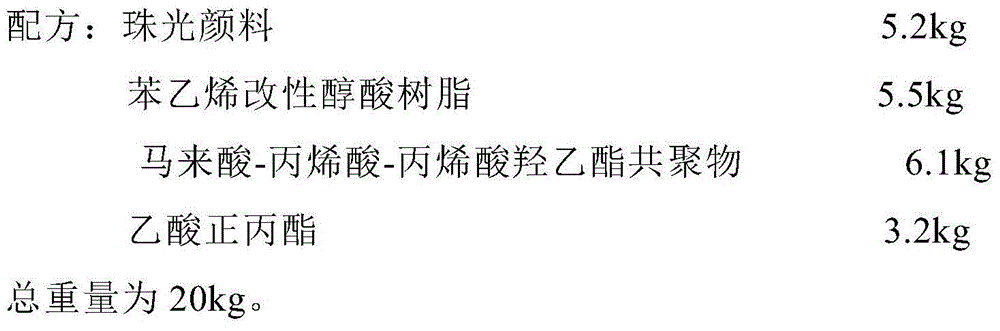

Embodiment 3

[0049]

[0050] Preparation:

[0051] 3.1 Weighing ingredients: Weigh each raw material according to the above formula into different stainless steel barrels for later use;

[0052] 3.2 Dispersion: Put 3.2kg of n-propyl acetate in a mixing tank, slowly add 5.2kg of pearlescent pigment into n-propyl acetate under stirring until the pearlescent pigment is completely dissolved, continue stirring, and mix 11.6 kg of styrene-modified alkyd resin and maleic acid-acrylic acid-hydroxyethyl acrylate copolymer mixed binder was gradually added to the pearlescent solution, stirred and dispersed evenly;

[0053] 3.3 Potting and packaging: Accurately weigh a certain amount of pearlescent ink according to the weight of the package, put it into the ink barrel, cover and seal the barrel, and stick a label to obtain the finished pearlescent ink.

[0054] After the production of the above ink is completed and placed for 3 months, there is no hard sediment at the bottom, and it can be evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com