Method for production of p-xylene

A technology for para-xylene and xylene, applied in the field of para-xylene production, can solve the problems of many equipment, high energy consumption, long process, etc., so as to reduce energy consumption, reduce enterprise operating costs, reduce equipment investment and floor space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

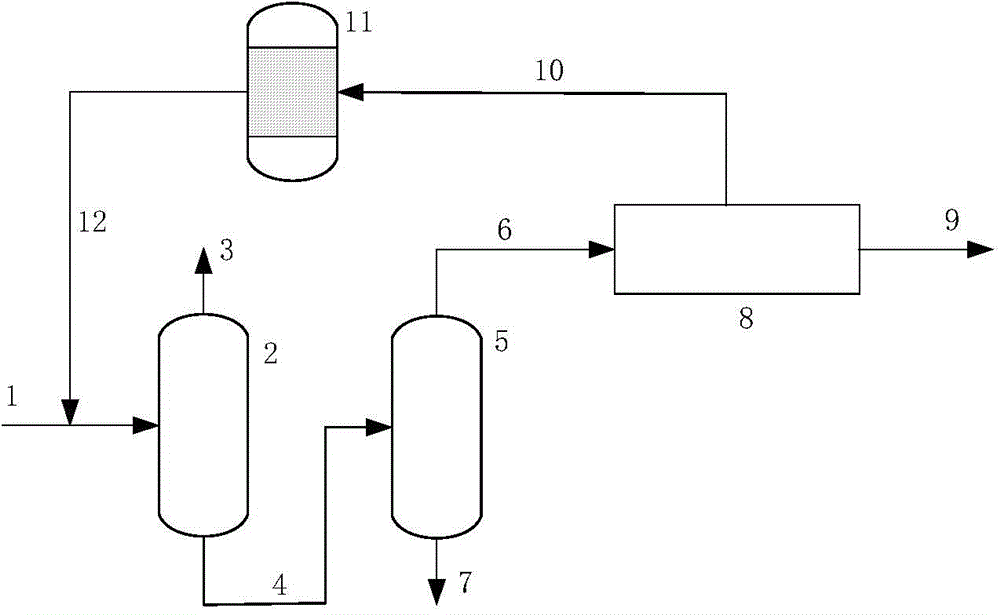

[0015] A method for producing p-xylene. The raw material containing C8 aromatics mixture enters a rectification tower, and the C8 aromatics mixture is separated from the side line of the rectification tower. The top of the tower is light hydrocarbons below C7, and the bottom of the tower is heavy hydrocarbons above C9 and C8 aromatics mixture. To the adsorption separation unit, contact with the adsorbent and separate to obtain p-xylene, m-xylene or ethylbenzene stream, and the remaining C8 aromatics are sent to the isomerization unit. Under the action of the isomerization catalyst, the generated isomerized C8 aromatics are used as The feed is recycled back to the rectification column.

[0016] Preferably, the raw material containing C8 aromatics is a mixed hydrocarbon containing ethylbenzene, p-xylene, o-xylene and m-xylene. The light hydrocarbons below C7 refer to hydrocarbons such as aromatic hydrocarbons, alkanes or cycloalkanes with carbon atoms below 7; the heavy hydrocar...

Embodiment 1

[0039] Example 1 illustrates the operating parameters and energy consumption of the method for producing p-xylene provided by the present invention.

[0040] Attached figure 2 The device and process shown are adsorption separation to produce p-xylene, and a 600,000-ton / year p-xylene device is used. attached figure 2 The single rectification column process flow diagram of the production p-xylene provided by the present invention, with attached figure 1 The difference in the shown process flow is that a rectification column is used instead of the conventional two-tower process to purify the feed for the adsorption separation unit. The equipment used is shown in Table 1, and the operating parameters and energy consumption of the device are shown in Table 2.

Embodiment 2

[0042] Example 2 illustrates the operating parameters and energy consumption of the method for producing p-xylene provided by the present invention.

[0043] Attached image 3 The process shown is adsorption and separation to produce p-xylene, and a 600,000-ton / year p-xylene device is used. attached image 3 The process flow diagram of the dividing wall type rectifying tower for the production of p-xylene provided by the present invention, with attached figure 2 The process flow shown is different in that the appended image 3 The rectification tower 2 adopted is a dividing wall rectification tower. Light hydrocarbons below C7 are extracted from the top of the dividing wall rectification tower 2, heavy hydrocarbons above C9 are extracted from the bottom of the tower, and aromatic hydrocarbon mixtures of C8 are extracted from the side line of the dividing wall rectifying tower. The equipment used is shown in Table 1, and the operating parameters and energy consumption of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com