Comprehensive processing process of culturing farm cow dung waste water

A comprehensive treatment and farm technology, applied in the field of farm waste treatment, can solve the problems of surrounding environmental pollution, unsolved liquid part of cow dung, low degradation load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

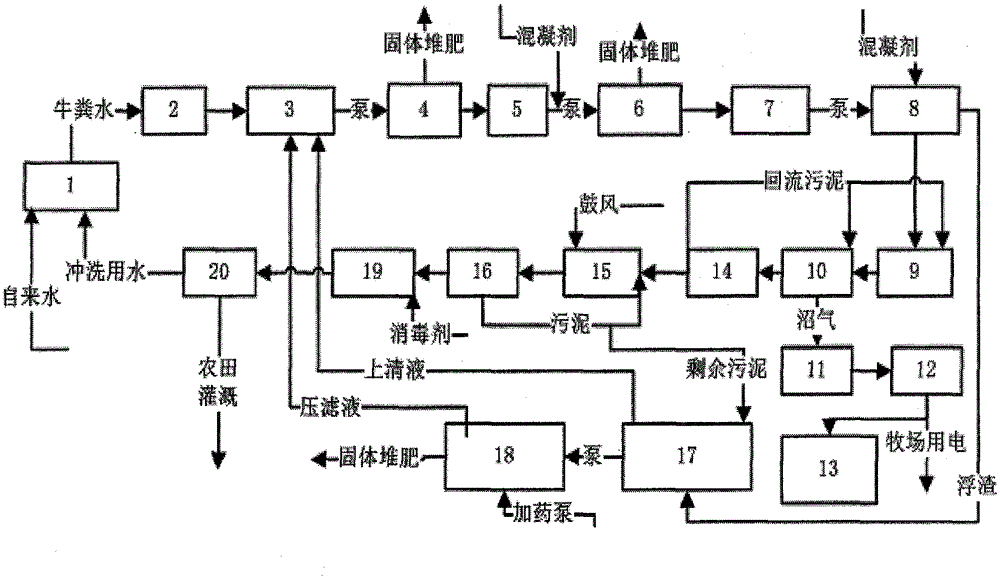

[0023] Process step of the present invention is described in detail below in conjunction with accompanying drawing:

[0024] As shown in Figure 1:

[0025] 1) After the cow dung water produced by the cowshed and milking center 1 in the dairy farm is collected, the channel passes through a coarse grid 2 under the action of gravity to intercept non-cow dung debris and then pours it into the slag storage tank 3. The grid gap is 50mm, which is mainly used to filter out large impurities and non-cow manure waste;

[0026] 2) A submersible mixer and a submersible sewage pump are arranged in the slag storage tank 3, and the submersible sewage pump in the slag storage tank 3 lifts the cow dung water to two mirror grilles 4 for filtering, and is used to remove most of the dung, The gaps of the two mirror grids are 1mm and 0.1mm respectively, and the lower part of the grid is equipped with a screw extrusion and transmission function device, which can directly squeeze and dehydrate the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com