Oxidation furnace for continuous production of high-purity titanium dioxide and production method thereof

A titanium dioxide, high-purity technology, applied in titanium oxide/hydroxide, titanium dioxide, chemical industry and other directions, can solve the problems of many impurities in production, low production efficiency, low output, etc., to save energy, improve use efficiency, improve The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

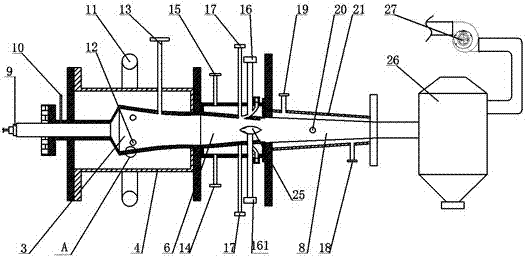

[0030] Example: The method of continuous production using high-purity titanium dioxide is:

[0031] 1. Preheating: Toluene and oxygen are introduced into the oxidation furnace, and the toluene combustion section 3 of the furnace body heats the oxygen by the heat generated by the combustion of toluene, so that the temperature in the furnace reaches 1800℃, which is the most favorable environment for the generation of titanium dioxide. The calcination time is 30min Air pressure 10000Pa;

[0032] 2. Reaction: inject titanium tetrachloride into the bathroom section 6 in the oxidation furnace, and spray the chlorination

[0033] Potassium and potassium chloride are one-thousandths of titanium tetrachloride, which can control the calcination process of titanium dioxide to make the size and softness of the particles moderate. At the same time, the salt treatment agent also acts as a crystal form accelerator; in the commutator Under the action of 25, a violent oxidation reaction occurs wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com