Method for low-stress injection moulding of amorphous or microcrystalline polyamides and also correspondingly produced low-stress polyamide moulded articles

A polyamide, low-stress technology, applied in the field of molded products, can solve the problems of low stress crack resistance, impact on the performance of injection molded products, etc.

Active Publication Date: 2016-01-27

EMS PATENT AG

View PDF6 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, it has not been recognized that the coordination of these parameters with each other may have an impact on the performance of injection molded parts

In particular, it remains problematic that low stress cracking resistance is observed in the case of moldings produced by injection molding from amorphous or microcrystalline molding compounds

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

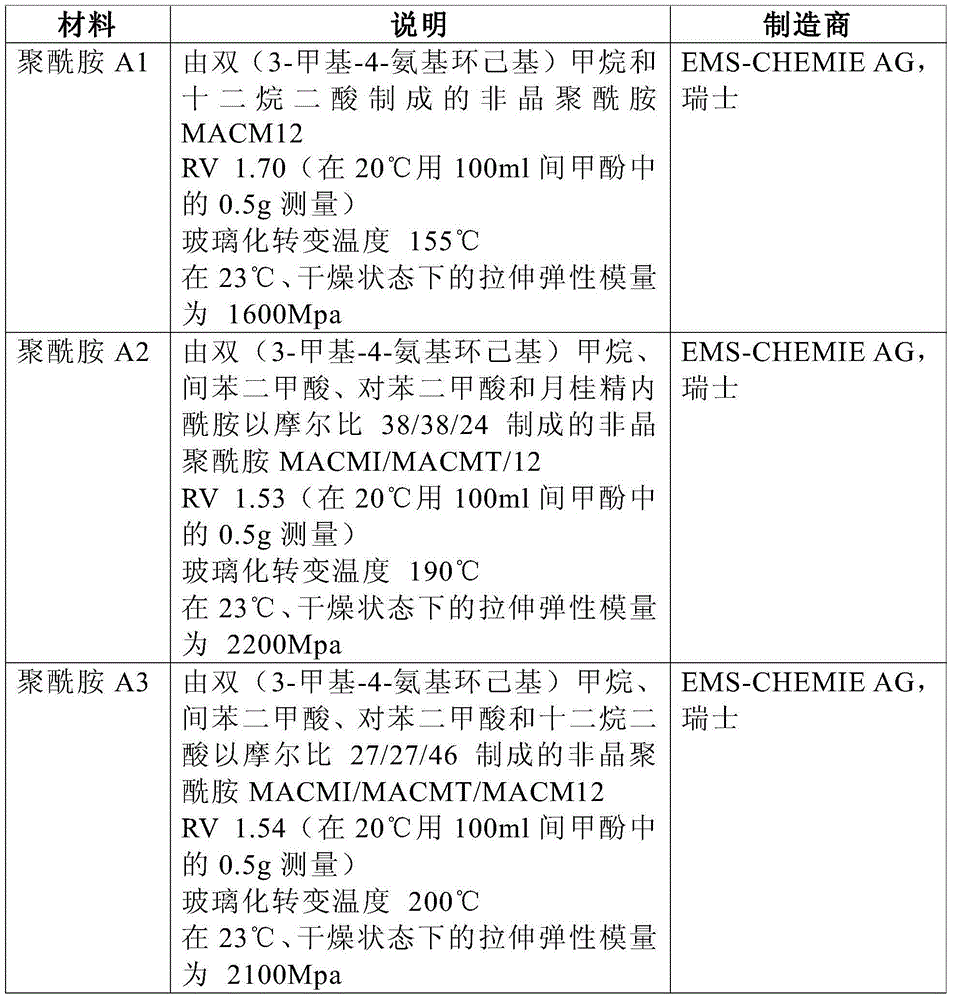

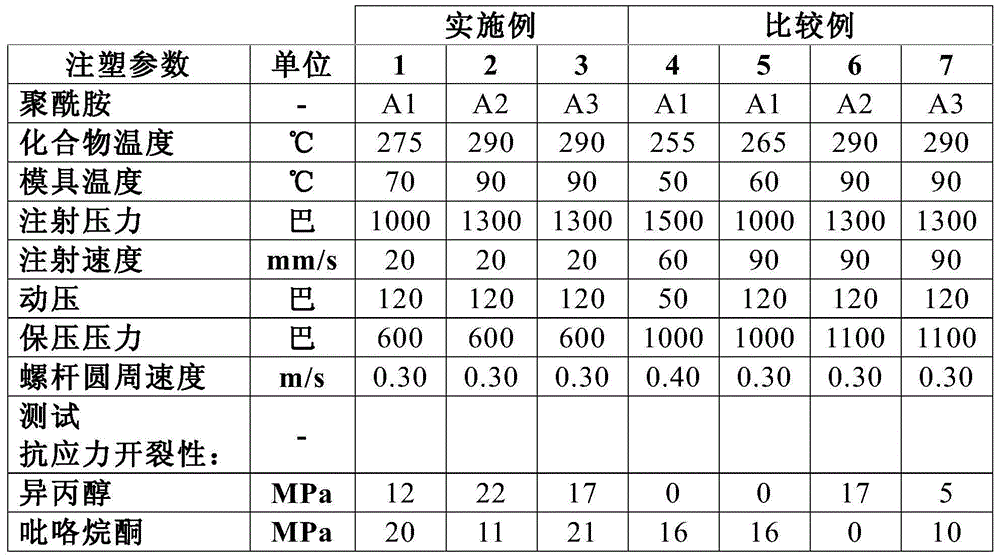

[0054] The invention is illustrated in more detail with reference to the examples that follow without restricting the invention to the specific parameters exemplified.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| enthalpy of fusion | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to a method for low-stress injection moulding of amorphous or microcrystalline polyamides, in which a melt of the amorphous or microcrystalline polyamides is processed and injection moulded under specific conditions. Hence, low-stress moulded articles made of the amorphous or microcrystalline polyamides can be produced by injection moulding. The present invention relates in addition to the correspondingly produced moulded articles.

Description

technical field [0001] The invention relates to a method for low-stress injection molding of amorphous or microcrystalline polyamides, wherein a melt of amorphous or microcrystalline polyamide is processed and injection molded under specific conditions. Thus, low-stress molded articles made of amorphous or microcrystalline polyamides can be produced by injection molding. The invention also relates to the correspondingly produced moldings. Background technique [0002] Methods for injection molding amorphous or microcrystalline polyamide molding compounds are known from the prior art. For example, from EP 1369447 A1 it is known to process amorphous or microcrystalline polyamides by injection molding, for example PAMACM12 or PAMACM12 / PACM12 by injection molding with different ratios of MACM and PACM. [0003] Corresponding possibilities for processing amorphous polyamides are likewise known from EP1397414A1, EP1979396A1 and EP2055743A1. [0004] During the injection molding...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C45/77B29C45/78B29C45/73C08L77/06

CPCB29C45/0055B29K2077/00C08L77/08B29C45/73B29C45/77B29C45/78C08L77/06B29C45/0001B29C45/0025B29K2995/0039B29K2995/0041C08J5/00C08J2377/02C08J2377/06

Inventor 博托·霍夫曼亚历山大·兰普艾蒂安·埃普利

Owner EMS PATENT AG

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com