A method of CNC milling without allowance for aircraft skin

A technology for aircraft skin and CNC milling, applied in milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of overall skin deviation, inability to be widely used, large gap between suction cups, etc., and achieve the effect of reducing positioning accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment A suction cup type flexible tooling

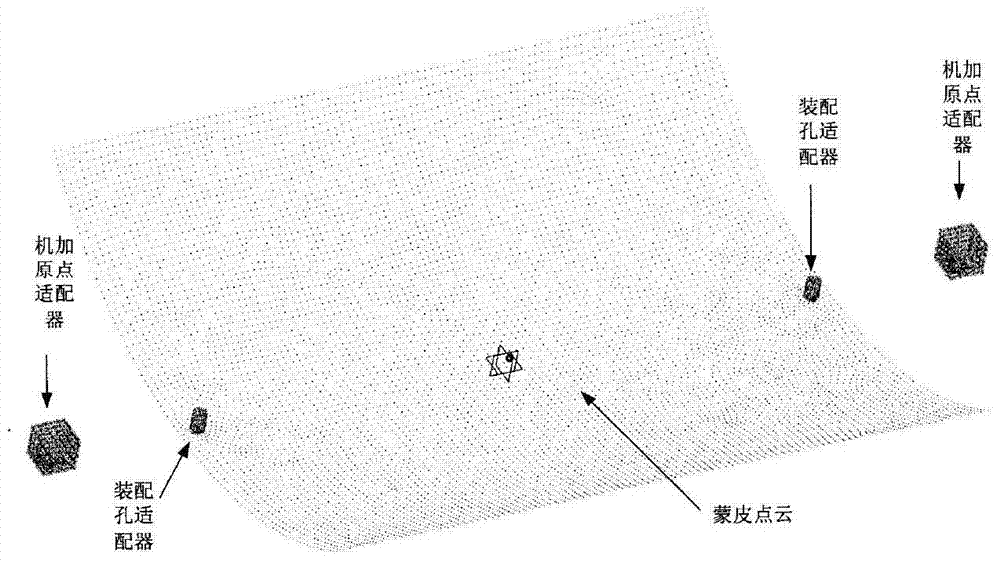

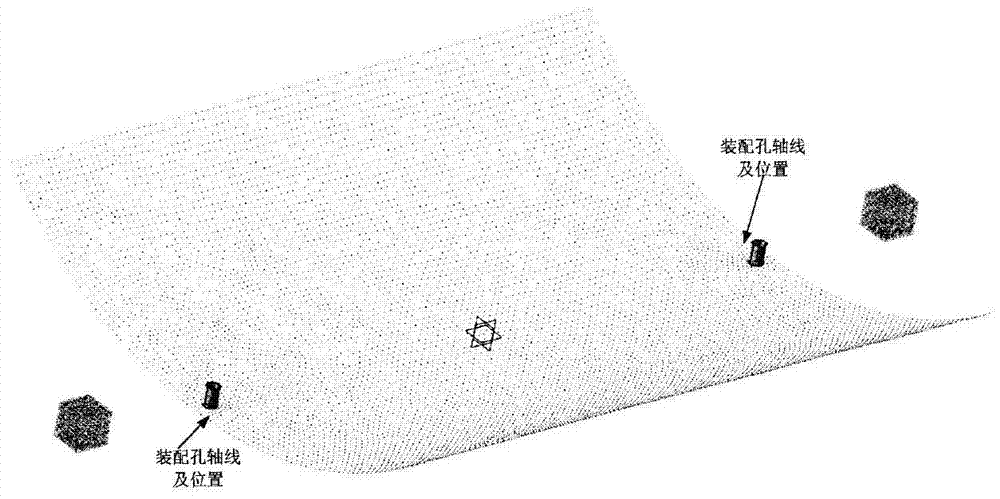

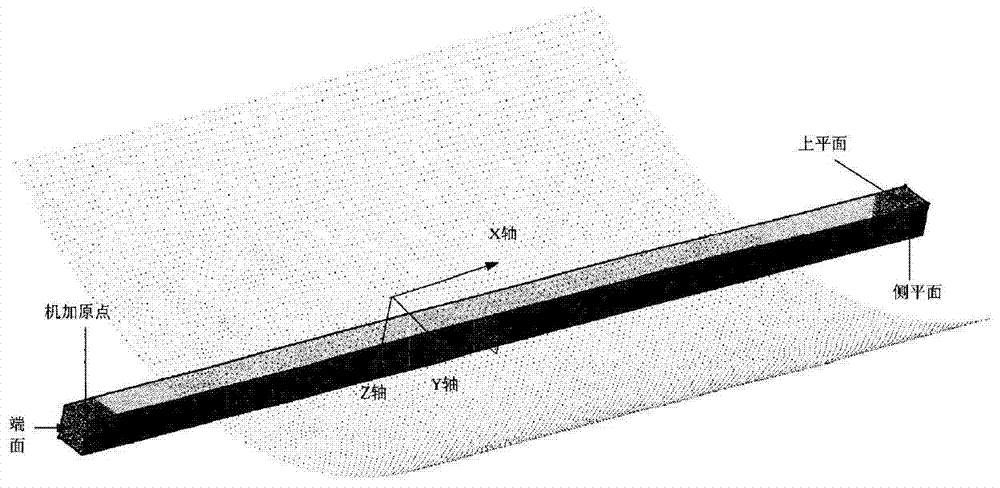

[0069] Such as Figure 7-22 Shown is a suction cup-type flexible tooling based on the above method, such as Figure 8 The shown flexible tooling includes a tooling frame, several double-bar support units 10, several four-bar support units 11 and several reference support units 12 arranged on the tooling frame; Figure 8-10 The tooling frame shown has a base 4, on which a connecting bracket 5 is provided, and on the connecting bracket 5, several assembling-type supporting plates 8 are provided, and the following supporting plates 8 and the connecting bracket 5 pass through the fastening assembly 6 and the positioning pin 7 are fastened on the base 4; each conformal support plate 8 is provided with several mounting holes, and the mounting holes are equipped with tensioning sleeves 9, and the connecting rods 2 are sequentially penetrated into the coaxial joints on the conformal support plate 8. In the installation hole, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com