Marine diesel engine exhaust gas desulfurization high-reliability dirt discharge delivery device

A technology for marine diesel engines and exhaust gas, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high technical difficulty and high reliability requirements of exhaust gas desulfurization equipment, and achieve the effect of reducing failure probability and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

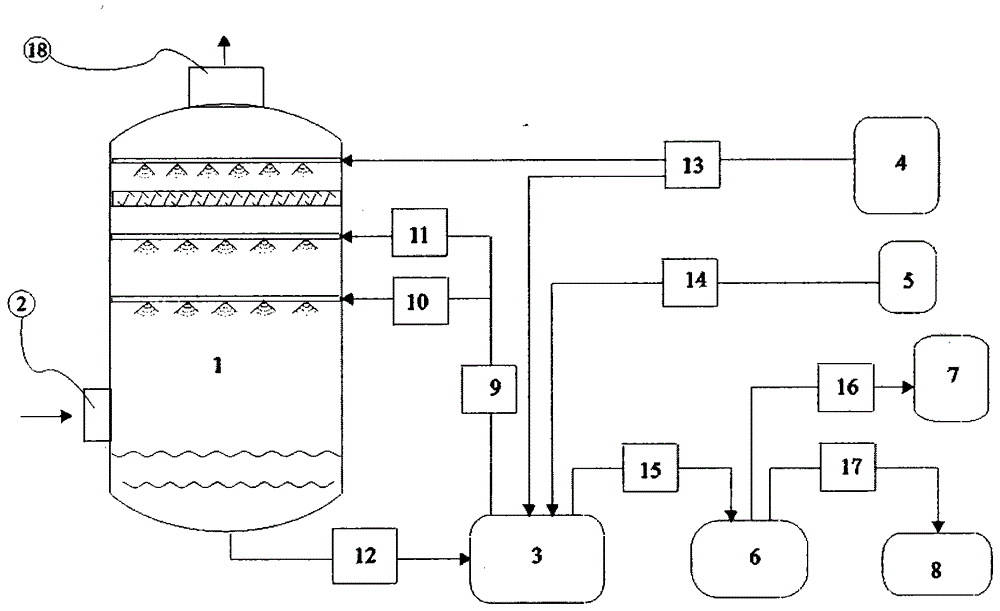

[0017] First of all, according to the requirements of desulfurization of diesel engine exhaust gas in the process of sailing and leaving the port, the water tank (4) and the lye tank (5) in the system store sufficient lye and water, and the water tank (4) and the neutralization processor ( 3) Connect with the cleaning and dosing water delivery and measurement and control device (13) through the pipeline. The lye tank (5) is connected to the neutralization processor (3) through pipelines and lye delivery and the measurement and control device (14), and the lye and water are input into the neutralization processor (3) to prepare desulfurization at the required concentration. aqueous solution.

[0018] The exhaust gas discharged during the working process of the marine diesel engine is firstly cooled to below 80 degrees by heat exchange, and then enters the middle and lower part of the washing tank (1) through the air inlet channel.

[0019] The spray device in the upper part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com