Cassava alcohol residue feed fermented by multiple microorganisms and preparation method and application of cassava alcohol residue feed

A technology of cassava alcohol residue and fermented feed, applied in animal feed, animal feed, application, etc., can solve the problems of high cost, limited cassava residue, poor strain combination, etc., and achieve the effect of increasing the number of probiotics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Determine the ratio of fermentation raw materials

[0074] The additions of cassava alcohol residues were 50%, 60%, and 70%, the additions of wet-process sugar residues were 10%, 20%, and 30%, and the additions of corn husks were 8%, 18%, and 28%, respectively. The amount of calcium carbonate added was 2%, a combination test was carried out, and the raw material ratio of the fermented feed was finally determined to be 60% (w / w) of cassava alcohol residue, 20% (w / w) of wet sugar residue, and 18% (w / w) of corn husk / w), the buffer calcium carbonate was added to adjust the pH, and the addition amount was 2% (w / w).

Embodiment 2

[0076] Screening of fermentation strains

[0077] 2.1 Screening of Bacillus strains

[0078] Five strains with high amylase production and strong antibacterial activity were screened out from nine strains of spores through the amylase production test and bacteriostatic test, namely Bacillus licheniformis 1.265 (CGMCC), Bacillus amyloliquefaciens 1.769 (CGMCC), Bacillus subtilis 1.1413 (CGMCC), Bacillus subtilis 1.836 (CGMCC), Paenibacillus forage 1.3772 (CGMCC).

[0079] 2.2 Screening of lactic acid bacteria strains

[0080] Through the lactic acid production performance experiment of lactic acid bacteria, 4 strains of lactic acid bacteria with high acid production were screened from 6 strains of lactic acid bacteria, namely Lactobacillus plantarum 1.557 (CGMCC), Lactobacillus plantarum 1.2158 (CGMCC), Lactobacillus brevis 1.214 (CGMCC), Bacillus coagulans 1.3220 (CGMCC).

[0081] 2.3 Screening of strains suitable for solid-state fermentation

[0082] First, the 4 strains ...

Embodiment 3

[0084] Optimization of fermentation conditions

[0085] 3.1 Optimization of the mixing ratio of fermented feed spores and lactic acid bacteria

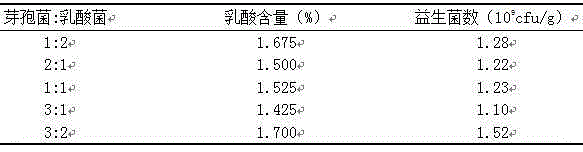

[0086] The 2 strains of spores and 2 strains of lactic acid bacteria that were screened were activated for 2 generations, inserted into the pre-mixed fermentation material, the inoculation amount was 5%, and the inoculation ratios of spores and lactic acid bacteria were 3:1, 3:2, 1:1 respectively. 1. The inoculation ratio of 2 strains of spores is 1:1, and the ratio of inoculation of 2 strains of lactic acid bacteria is 1:1. After fermentation in a constant temperature biochemical incubator at 32°C for 4 days, the lactic acid content and the number of probiotics are detected. According to the results, it is finally determined that the mixing ratio of spores and lactic acid bacteria is 3:2.

[0087] 3.2 Optimization of the ratio of 2 strains of spores in fermented feed

[0088]Activate 2 strains of spores and 2 strains of lactic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com