A kind of preparation method of Jerusalem artichoke fermented milk drink

A production method and enzyme fermentation technology, applied in the direction of dairy products, lactobacillus, milk preparations, etc., can solve the problems of low number of active lactic acid bacteria, weak lactic acid bacteria, affecting the product market, etc. and flavor, increasing dietary fiber and prebiotic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

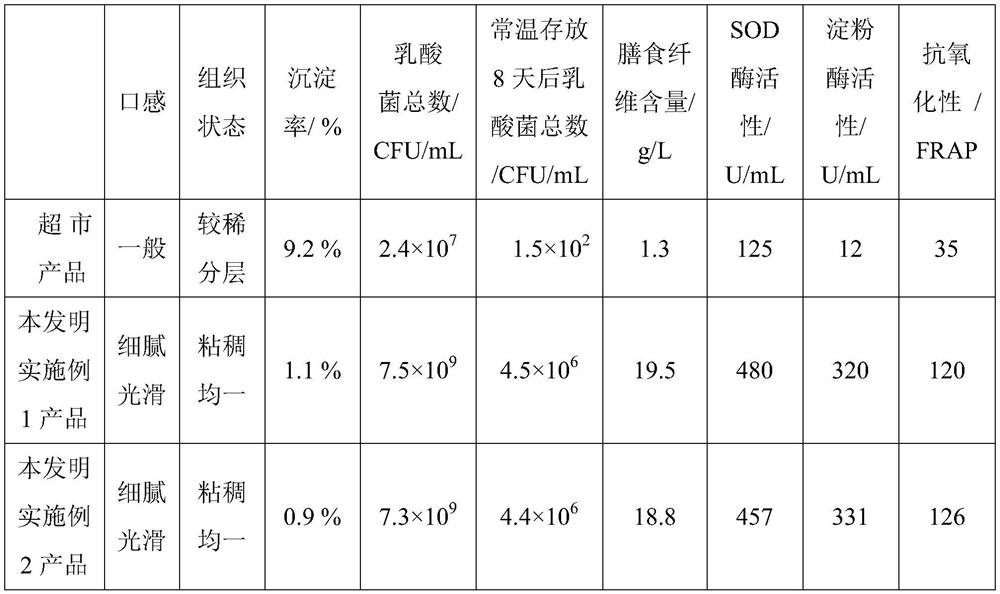

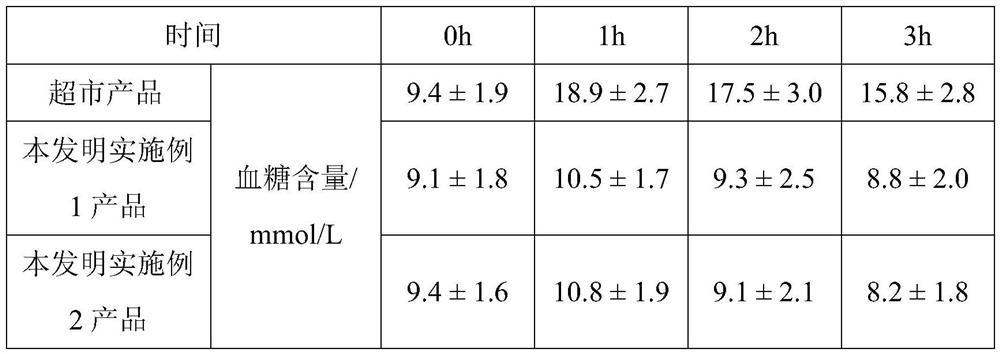

Embodiment 1

[0040] Take 1kg of fresh South Jerusalem artichoke No. 9 Jerusalem artichoke, wash, peel and beat, add 2kg of water, 0.25kg of apple juice and 2g of lactose to the Jerusalem artichoke slurry, mix evenly, quickly heat to 80°C, and ultrasonically treat at this temperature for 20min , the ultrasonic power is 500w, and the ultrasonic treatment mixture is 3.252kg. Take 1.2kg of ultrasonic treatment liquid and filter it with a 300-mesh filter cloth to obtain 0.9kg of filtrate. Take 120g of filtrate and 480g of sterilized milk to mix evenly, 300g of filtrate to mix evenly with 300g of sterilized milk, and 480g of filtrate to mix evenly with 120g of sterilized milk. Prepare 2:8, 5:5, 8:2 acclimation medium. Take 1.5g of Lactobacillus bulgaricus, 1.5g of Streptococcus thermophilus, 1.5g of Lactobacillus plantarum, and 1.5g of Lactobacillus rhamnosus, mix them evenly into the 2:8 medium, cultivate at 42°C for 3h, and then inoculate 30g of the culture solution into In the 5:5 medium, cu...

Embodiment 2

[0054] Take 2kg of fresh South Jerusalem artichoke No. 9 Jerusalem artichoke, wash, peel and beat, add 6kg of water, 0.4kg of tomato juice and 6g of lactose to the Jerusalem artichoke slurry, mix well, heat rapidly to 90°C, and ultrasonically treat at this temperature for 15min, The ultrasonic power is 600w, and 8.406kg of the ultrasonic treatment mixture is obtained. Take 2kg of the ultrasonic treatment solution and filter it with a 400 mesh filter cloth to obtain 1.7kg of filtrate. Take 200g of filtrate and 800g of sterilized milk and mix evenly, 500g of filtrate and 500g of sterilized milk, mix evenly with 800g of filtrate and 200g of sterilized milk, and prepare respectively 2:8, 5:5, 8:2 acclimation medium. Take 3.33g of Lactobacillus bulgaricus, 3.33g of Streptococcus thermophilus, 6.66g of Lactobacillus plantarum, and 6.66g of Lactobacillus rhamnosus, mix them evenly, add them to the 2:8 medium, cultivate at 40°C for 4 hours, and then take 100g of the culture solution f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com