Microwave cavity resonator and spinning preparation machine with same

A technology for cavity resonators and preparation machines, which is applied in resonators, waveguide devices, and material analysis using microwave means, and can solve the problems that air vibration cannot be arbitrarily improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

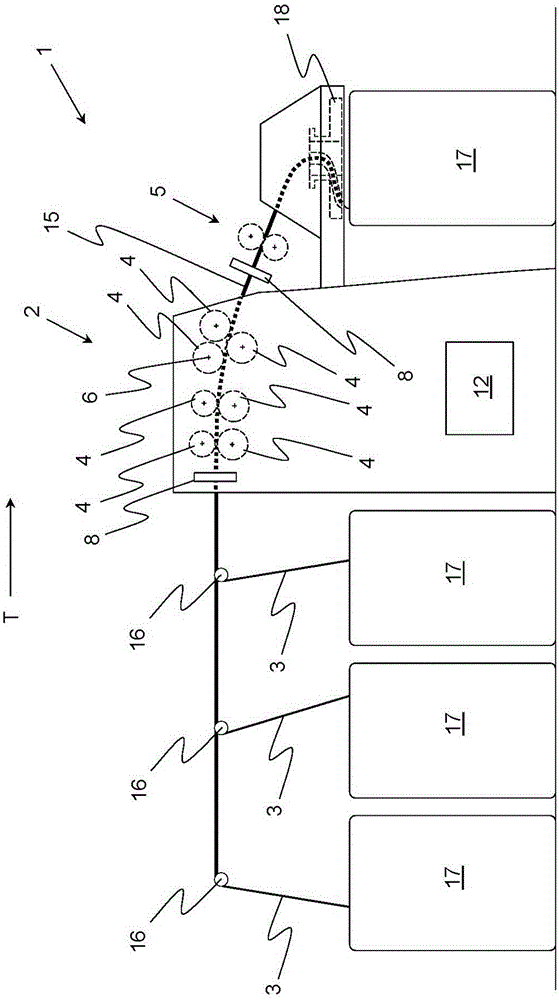

[0037] figure 1 Using a side view, the spinning preparation machine 1 for drawing (equalizing) a bundle of fiber material (fiber bundle 3) according to the present invention will be described using a draw frame as an example. During the operation of the draw frame, the fiber bundles 3 (e.g. individual fiber bundles) are removed from one or more so-called spinning pots 17 by means of a discharge device and passed through corresponding guides 16 of the draw frame drafting device 2 Transport (for example in the case of a multi-head draw frame the drafting unit 2 of the draw frame).

[0038] The drafting device 2 has a plurality of drafting device rollers 4 rotatable along corresponding axes of rotation 6 (only one of which is marked with a reference number) and transports the fiber bundle 3 in a clamped manner. The desired deformation of the fiber bundle 3 is achieved by the respective cylindrical lower rollers and the respective upper rollers in contact therewith having an inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com