Full-automatic inductance winding machine having large wire diameter

A fully automatic, winding machine technology, used in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of unstable quality of inductors, unstable quality, lack of labor, etc., to achieve stable product quality and service life. Long, productive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

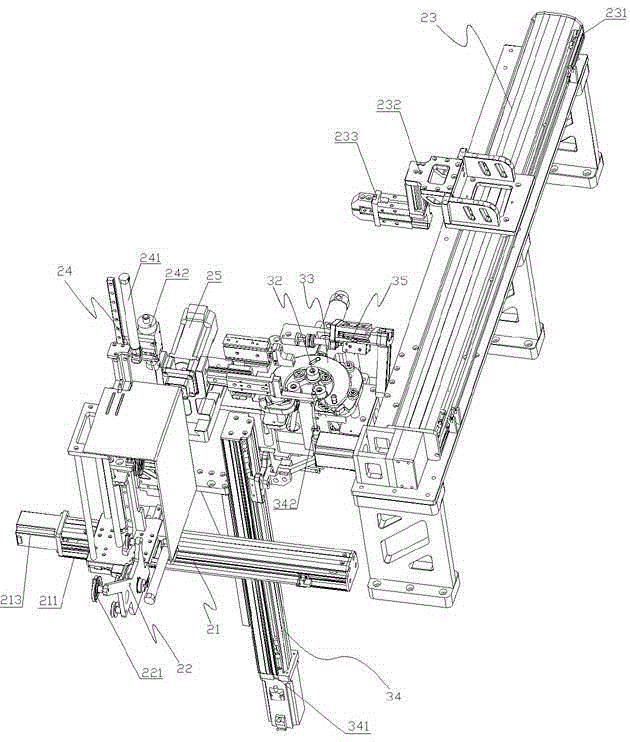

[0033] like Figure 1 to Figure 8 As shown, a fully automatic thick wire diameter inductor winding machine of the present invention is provided with:

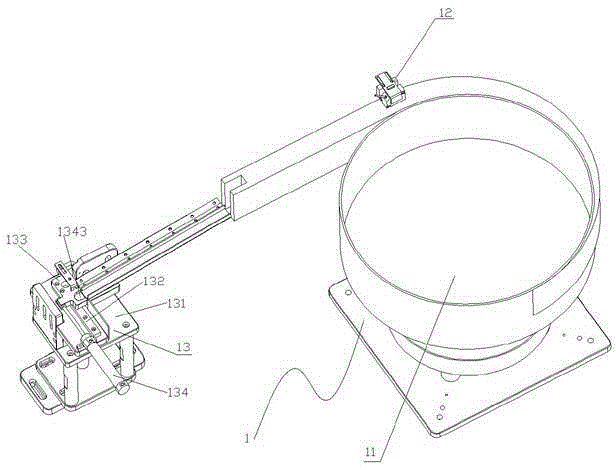

[0034] Magnetic ring feeding system 1, which is provided with a vibrating plate 11 with a discharge port, a screening device 12 installed on the vibrating plate 11, and a positioning device 13 located at the position of the discharge port set by the vibrating plate 11;

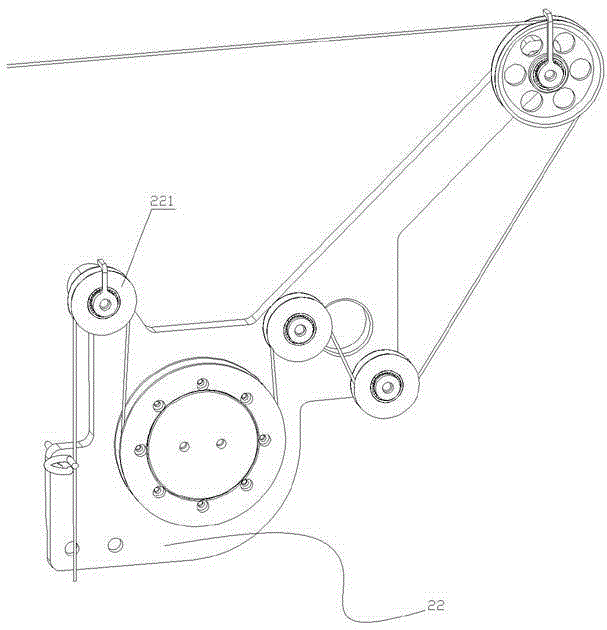

[0035] Wire pay-off system 2, which is provided with a tensioner 22, a wire pulling device 23 and a wire trimming device 24;

[0036] The winding system 3 is provided with an assembly station 31, a magnetic ring rotation device 32 for adjusting the angle of the magnetic ring is arranged at the lower end of the assembly station 31, and a magnetic ring for clamping the magnetic ring is arranged at the upper end of the assembly station 31 a clamping device 33 , a thread hooking device 34 located beside the assembly station 31 and a thread clamping device 35 locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com