High-temperature refractory cable in aero-engine region

An aero-engine, high-temperature refractory technology, applied in the field of high-temperature refractory cables, can solve the problems that the performance does not fully meet the high reliability requirements of aerospace, the outer diameter and weight cannot be achieved, and the service life is short, so as to improve safety and reliability. , Improve the high and low temperature resistance performance, the effect of reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

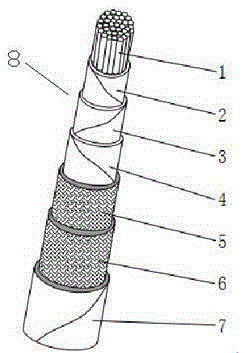

[0013] like figure 1 As shown, a high-temperature fire-resistant cable for an aero-engine area includes a cable body 8, and the cable body 8 includes a conductor 1, an inner insulating layer 2, an outer insulating layer 3 and an outer sheath layer 7, and the inside of the cable body 8 is A plurality of conductors 1 are provided; the conductor 1 is tightly wrapped with an inner insulating layer 2; the inner insulating layer 2 is extruded and wrapped with an outer insulating layer 3; the outer insulating layer 3 is extruded and wrapped with a layer of heat insulation layer 4; the heat insulation layer 4 is extruded and wrapped with a layer of refractory layer 5; the refractory layer 5 is extruded and wrapped with a layer of shielding layer 6; the shielding layer 6 is extruded and wrapped with a layer of outer sheath layer 7.

[0014] The conductor 1 is formed by twisting multiple strands of nickel-plated copper wires, which not only improves the current-carrying capacity of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com