Configuration design method for anti-explosion container made of hybrid fiber composite material

A composite material, hybrid fiber technology, used in computing, special data processing applications, instruments, etc., can solve problems such as no composite material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

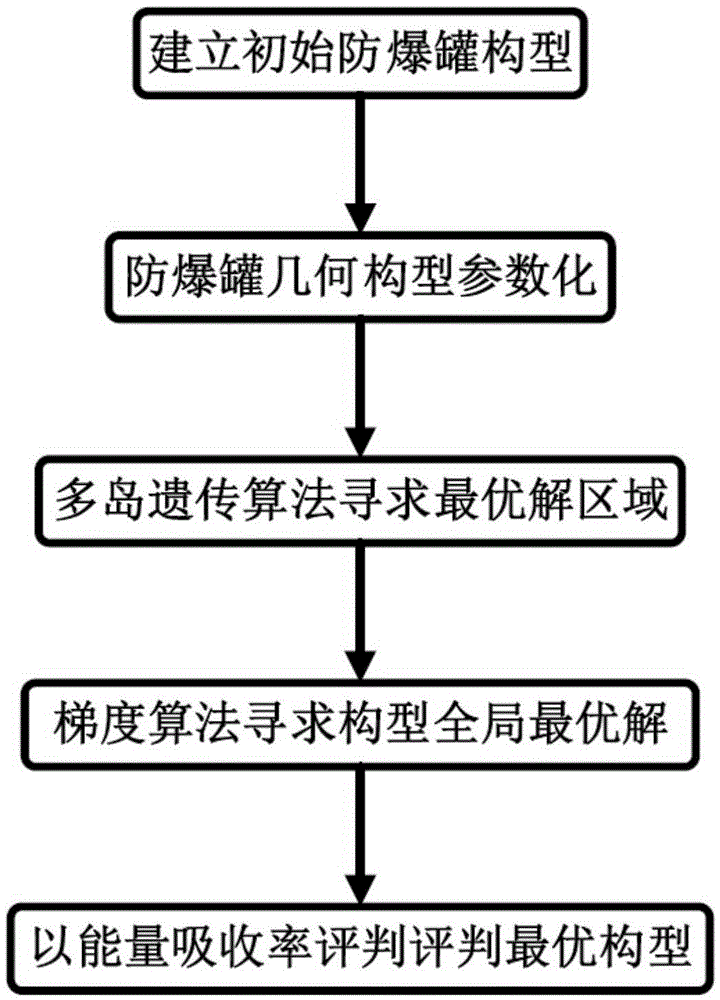

[0110] Such as figure 1 As shown, a hybrid fiber composite explosion-proof tank configuration design method, including the following steps:

[0111] S1. Establish an initial explosion-proof tank configuration that meets the preset conditions;

[0112] Design background: The explosive equivalent is 4 kg of TNT mass, and the initial explosion-proof tank configuration is as follows:

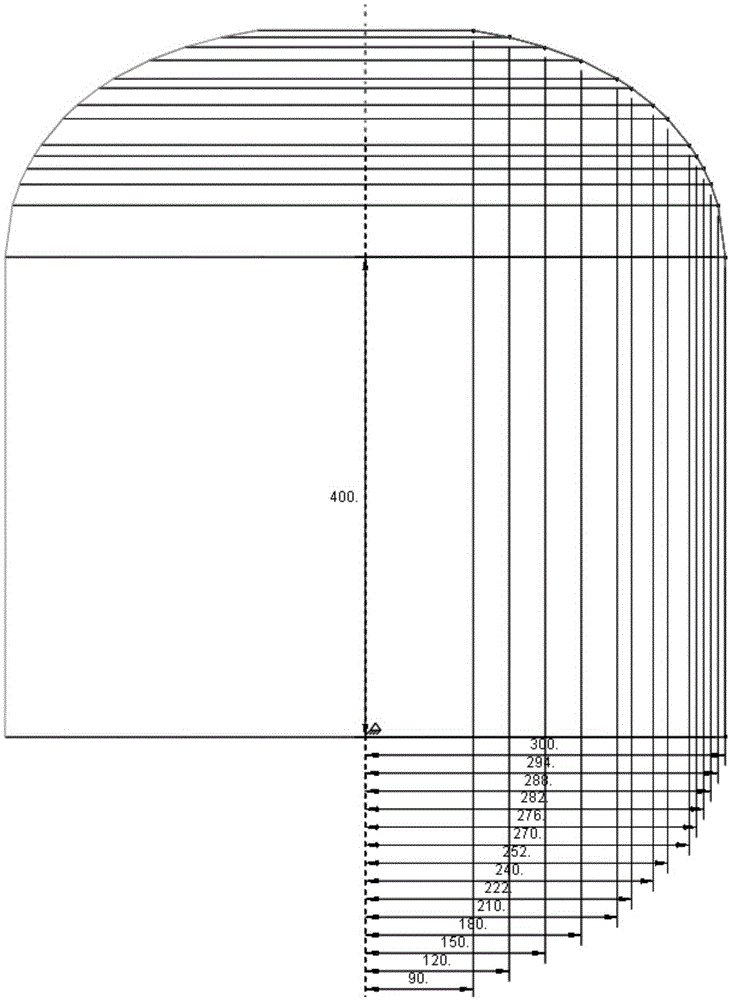

[0113] The initial configuration of the explosion-proof tank is a cylindrical container, and the length of the bus bar of the cylindrical container is set to 0.8m, the diameter is 0.6m, and the diameter of the holes at both ends is 0.18m; the fiber volume content in the composite material is 60%, and the curing degree is >85%. The fiber thickness of each layer of the straight section is 0.2mm; the mass of the straight section is limited to 90kg, the elastic modulus is >150GPa, and the composite fiber mixing ratio is set to Kevlar 49 fiber: carbon fiber = 45%: 55%.

[0114] Establish an ABAQUS mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com