Calculation method of flow process of single-component gas in anisotropic coal seam

An anisotropy and flow process technology, applied in calculation, special data processing applications, instruments, etc., can solve the problems of not considering the anisotropy of coal seams, and the inability to simulate mixed gas pressure injection to enhance coalbed methane mining, etc., to achieve numerical simulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

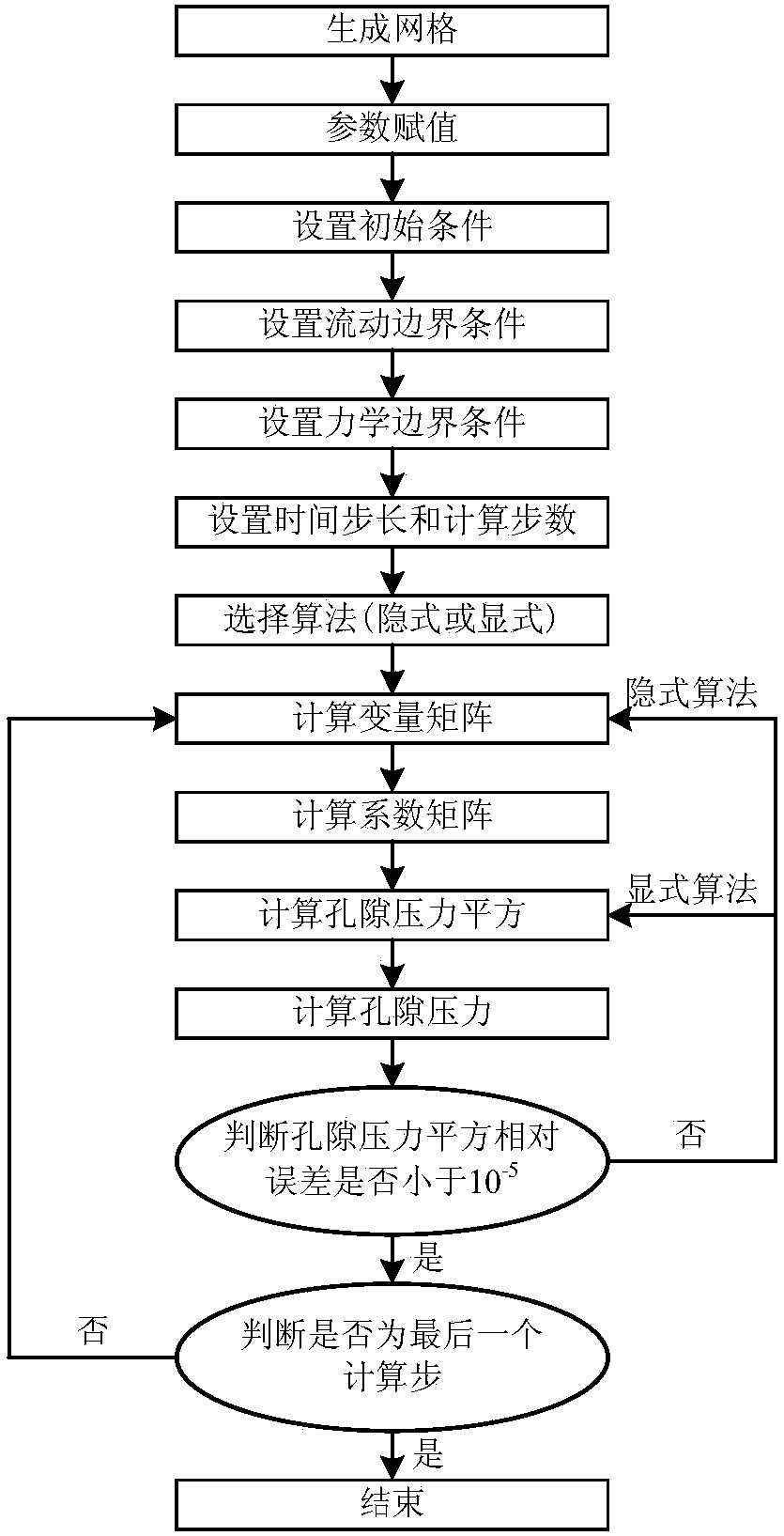

[0036] The calculation method of the single-component gas flow process in the anisotropic coal seam of the present invention, its preferred embodiment is:

[0037] include:

[0038] The model expression of gas flow governing equation in coal is:

[0039]

[0040] In the formula:

[0041]

[0042]

[0043]

[0044]

[0045]

[0046]

[0047]

[0048]

[0049]

[0050]

[0051]

[0052]

[0053]

[0054]

[0055]

[0056]

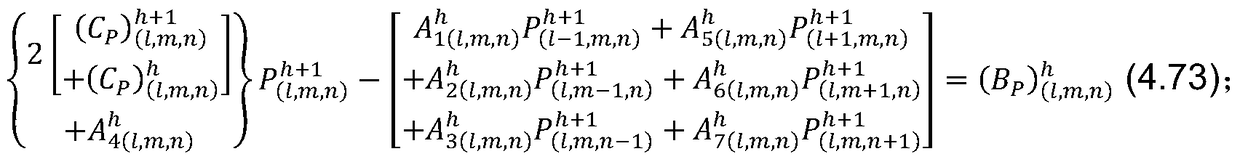

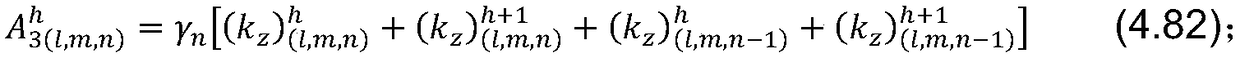

[0057] Neglecting the infinitesimal term in Equation 4.73 gives:

[0058]

[0059] In any time step, the Gauss-Seidel iteration format for solving Equation 4.90 is:

[0060]

[0061] where i is the ith iteration step.

[0062] According to the following basic assumptions:

[0063] Coal contains double pores, which are joints with larger size and pores with smaller size. The gas moves laminarly in the joints, and its motion law conforms to Darcy's law. The gas diffuses in the coal matrix, and its mot...

specific Embodiment

[0071] Basic assumptions:

[0072] Coal contains double porosity, which are joints with larger size and pores with smaller size. The gas moves laminarly in the joints, and its motion law conforms to Darcy's law. The gas diffuses in the coal matrix, and its movement law conforms to Fick's law.

[0073] Coal only contains single-component gas, which exists in the free state in the joints and pores, and exists in the adsorbed state on the surface of the joints and pores.

[0074] The gas in the joint is a Newtonian fluid, and its motion law conforms to Newton's law of viscosity.

[0075] All physical processes of gas in coal (including laminar flow, diffusion, adsorption and desorption) are isothermal processes.

[0076] The adsorption and desorption of gas in coal conform to the Langmuir isotherm adsorption equation, and the adsorption and desorption are reversible processes.

[0077] The solid skeleton of coal is immobile and its deformation velocity is zero.

[0078] The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com