High-efficiency energy-saving heating cooking bench boiler

A high-efficiency, energy-saving, stove-top technology, applied in the field of boilers, can solve the problems of low thermal efficiency, waste coal, and trouble, and achieve the effects of high thermal efficiency, avoiding poisoning, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

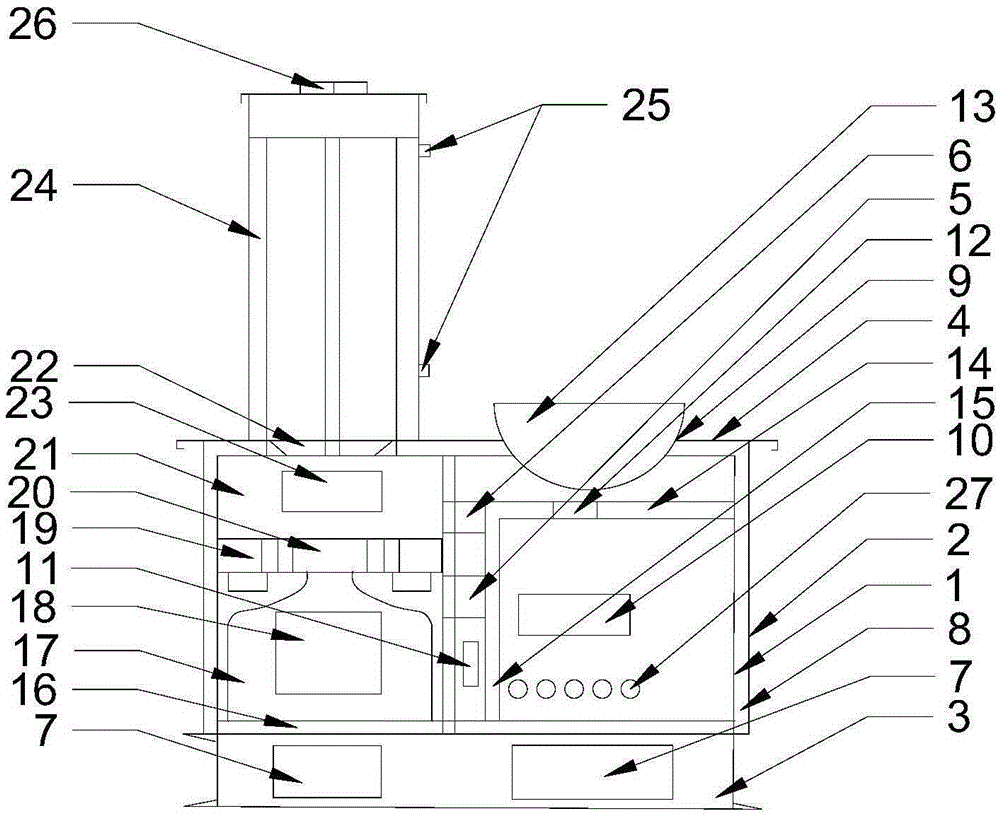

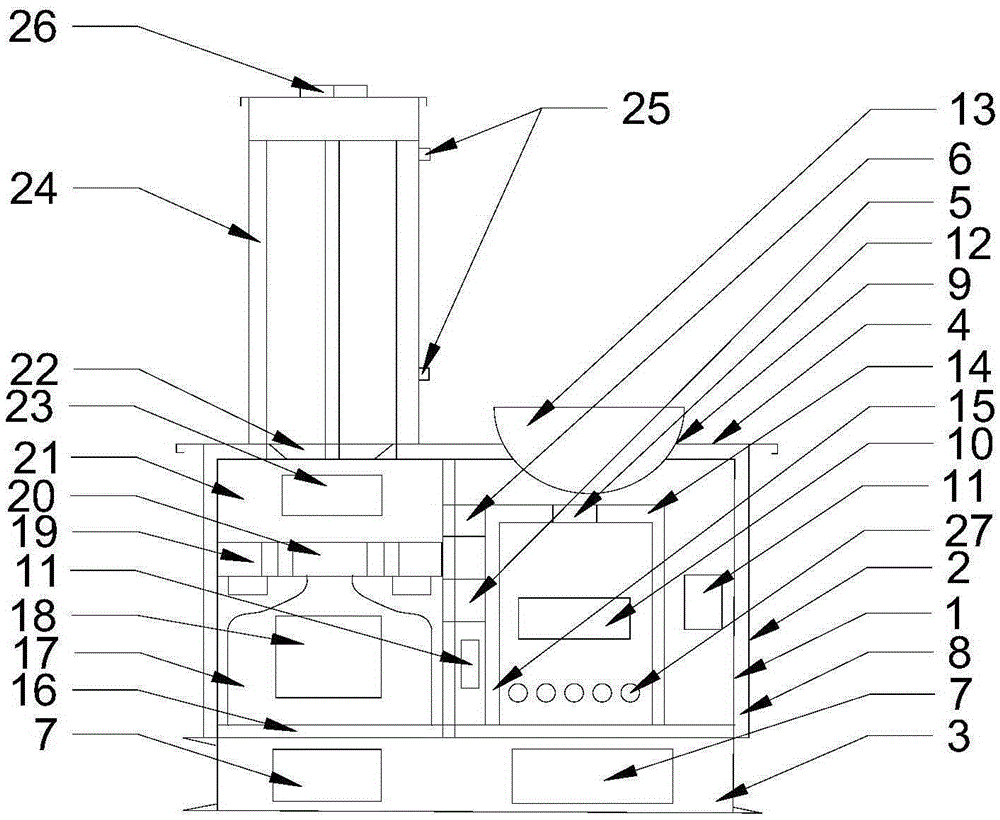

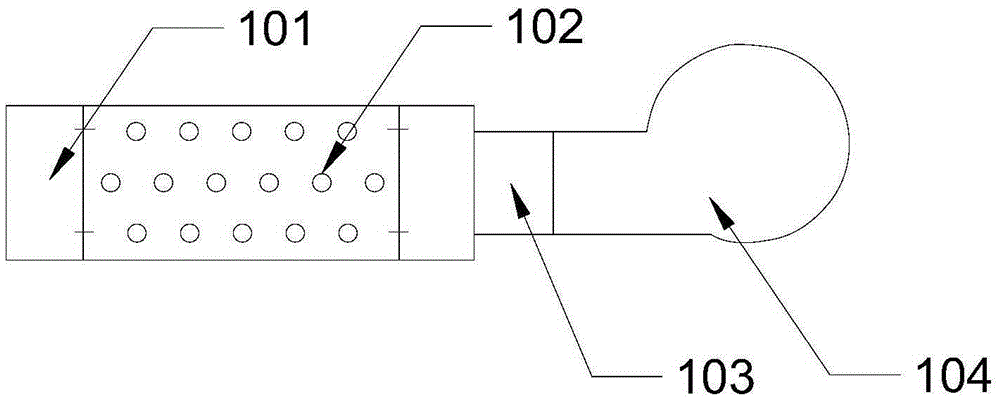

[0021] see Figure 1-3 , a high-efficiency and energy-saving heating stove boiler, comprising a furnace body, a base 3 and a stainless steel hob 4, the furnace body is installed above the base 3, the stainless steel hob 4 is installed above the furnace body, the furnace The body includes a furnace inner tank 1 and an outer furnace tank 2. The furnace inner tank 1 is located inside the furnace outer tank 2. The furnace inner tank 1 is divided into a boiler body and a boiler body by a first passage 5 and a second passage 6. The stove body, the boiler body is located on the left side of the stove body, and the bottom of the boiler body and the base 1 below the stove body are provided with an ash outlet 7, and the stove body also includes a stove eye 9, a furnace mouth 10 and Smoke exhaust port 11, the fire gathering hole 12 is arranged below the stov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com