Boiler monitoring system based on Internet of Things

A monitoring system and Internet of Things technology, applied in the field of boilers, can solve problems such as accident-prone, low boiler life, and inability to monitor boiler working status in real time, so as to improve accuracy and avoid false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

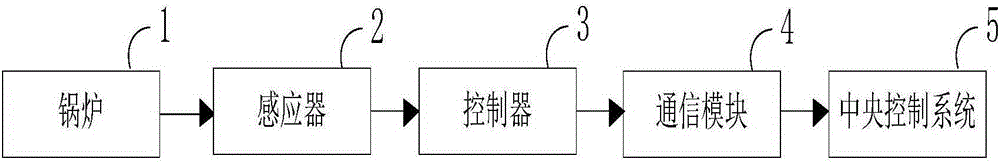

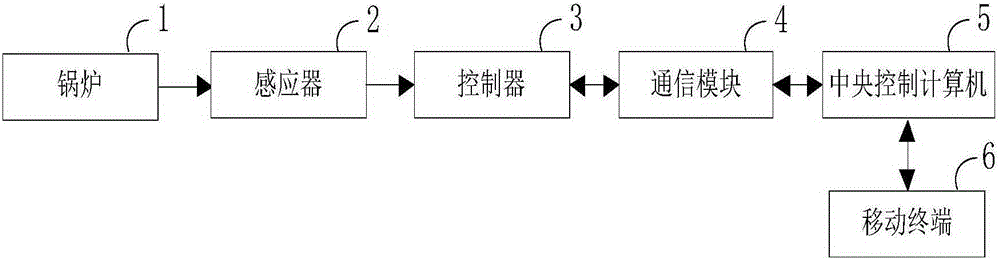

[0029] Such as figure 2 As shown, it is a structural block diagram of the first embodiment of a boiler 1 monitoring system based on the Internet of Things in the embodiment of the present invention.

[0030] The sensor 2 includes at least one or more of a liquid level sensor, a pressure sensor, a temperature sensor or a flame sensor, and sequentially collects the liquid level, pressure, furnace temperature and flame spectrum parameters of the boiler 1 through the above sensors, and sends them to Controller 3.

[0031] Specifically, the liquid level sensor is installed in the furnace, the pressure sensor is also installed in the furnace, the temperature sensor is also installed in the furnace, and their output ends are respectively connected to the controller; the flame sensor is installed outside the furnace A spectrum of the flame was taken close to the boiler heat.

[0032] Described controller 3 is any one in single-chip microcomputer, programmable logic controller 3, di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com